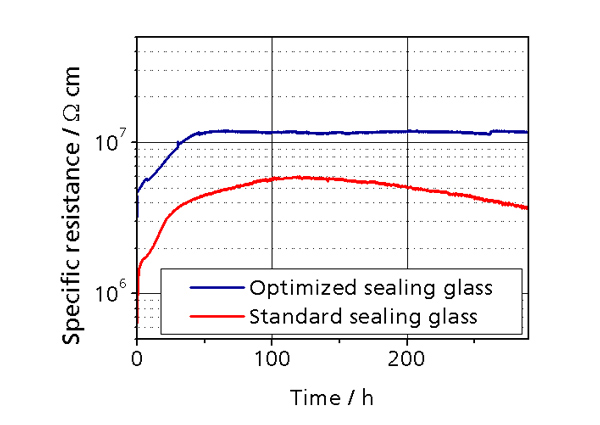

The use of sealing glasses for SOFC is coupled with rigid requirements to the glass properties. Beside a matched thermal expansion > 9 10-6 K-1 and viscosity behaviour the glasses must offer a high stability against interconnector materials, ceramic electrolytes and dual atmospheres under SOFC operating conditions. Additionally they have to guaranty the mechanical stability of SOFC stack. Only a successful match of all the properties and requirements mark longtime stable sealing glass. The Fraunhofer IKTS has developed partial crystallizing glasses for different types of SOFC (ASC, ESC) to seal interconnector frames and ceramic electrolytes. The glasses can be applied as pastes and tapes and have been successfully tested in more than 800 stacks various fuel gas compositions and testing times up to 10.000 h.

Examples and references

- Manufacturing, processing and quality management of glass frits in Charges >100kg from raw materials to ready for application sealing parts for the company Staxera (Dresden).

- Technology transfer of developed sealing glasses to the companies H.C. Starck and Kerafol