Using waste heat to generate power results in significant energy efficiency potentials. Thermoelectric generators (TEGs) offer the advantage of directly converting thermal energy into electricity without the use of high-maintenance moving components.

However, conventional TEGs use cost-intensive and toxic substances, such as bismuth or lead telluride, as active materials. These can be replaced by new, less expensive and more environmentally friendly materials, such as Half-Heusler alloys made of zirconium, titanium and tin. In addition, these materials allow operation at higher temperatures, which utilizes more waste heat. Due to the current layout of ceramic substrates with structured metallization, applied in multiple process steps, the production of these TEGs is currently still very cost-intensive.

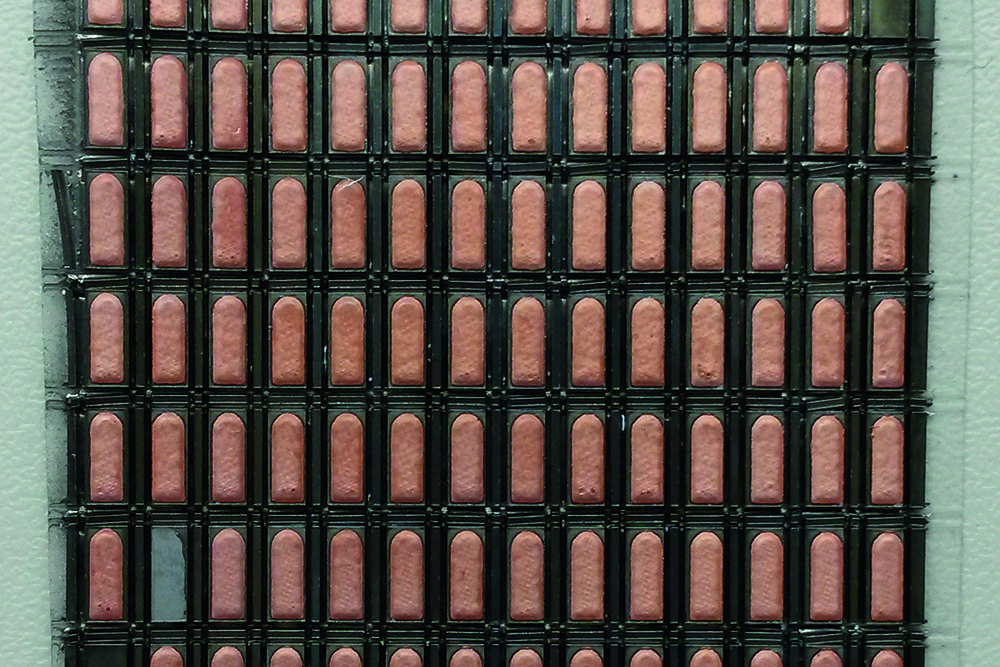

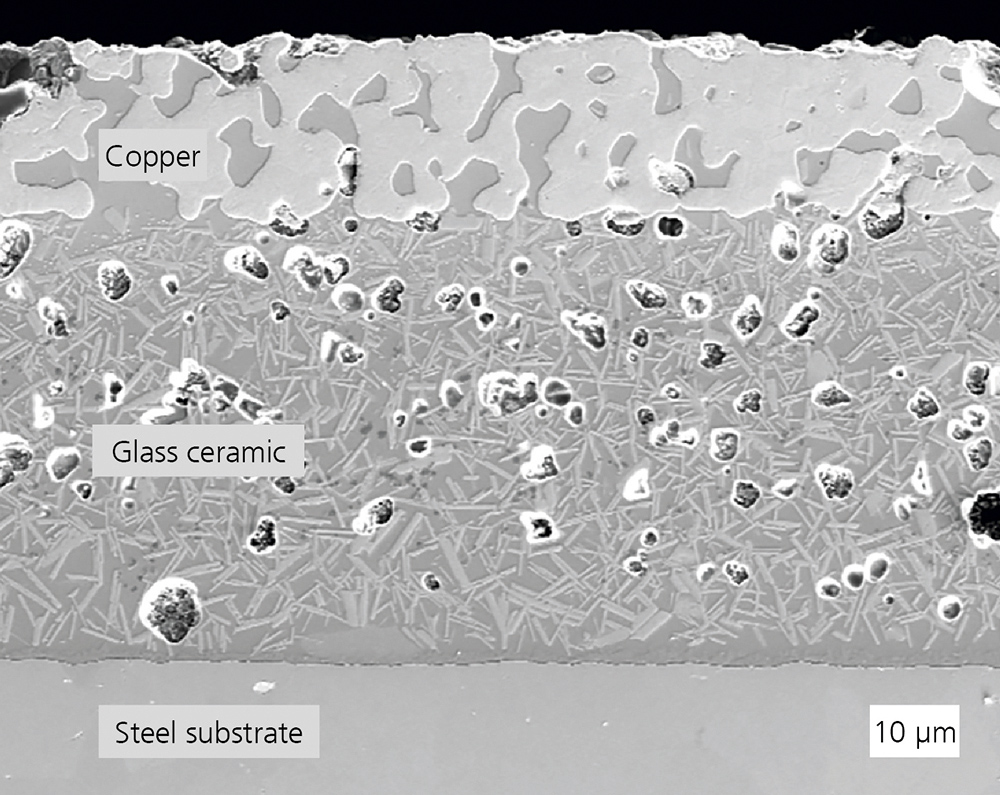

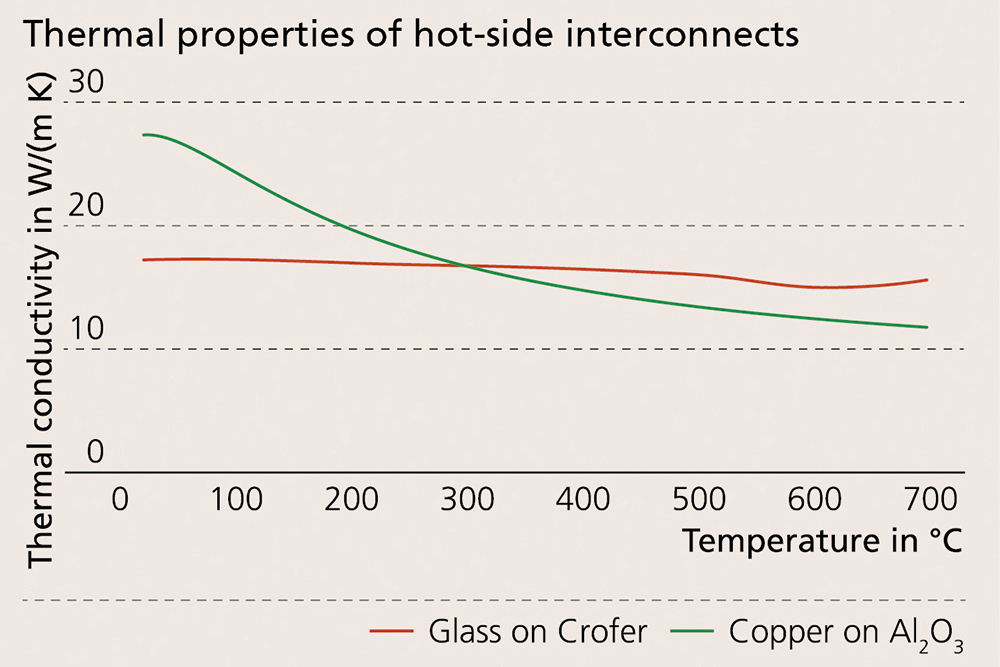

As part of the EU INTEGRAL project, Fraunhofer IKTS has developed an interconnect technology using the more cost-effective ceramic screen printing technology. In this process, inexpensive steel substrates are provided with dielectric coatings based on structured glass ceramics. The developed glass ceramic materials, with a high coefficient of thermal expansion, are particularly suitable for use at temperatures up to 600 °C. They can be applied as pastes using screen printing technology in layer thicknesses of approx. 50 µm and serve as a dielectric insulation layer. Pastes based on copper and silver are applied in thicknesses of up to 200 µm. They serve as contact layers for the thermoelectrically active materials. The thermal conductivity of the developed hot-side interconnects equals that of metallized Al2O3 ceramics at high temperatures. Fraunhofer IKTS can thus offer the technology for cost-effective and environmentally friendly TEGs – even as multiple connectors with increased reliability. In addition, this approach enables the production of segmented and wireable hot-side contacts.

Services offered

- Interconnect technology for elevated temperatures

- High-temperature joining technology

- Development of ceramic and metal pastes for high-temperature applications