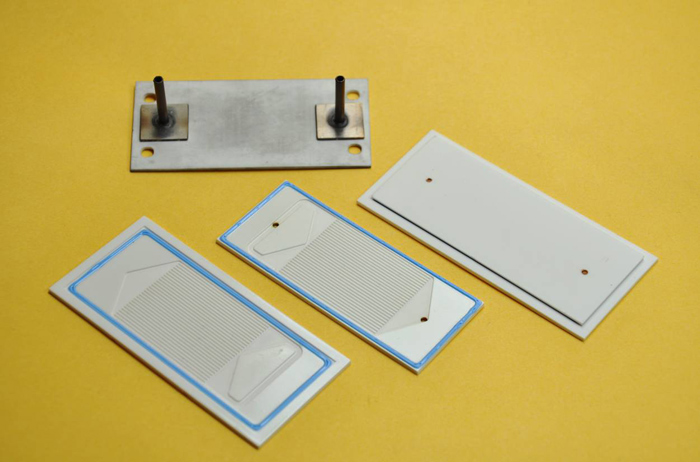

Components of a HTCC-microreactor for reforming processes sealing with crystallizing solder glasses

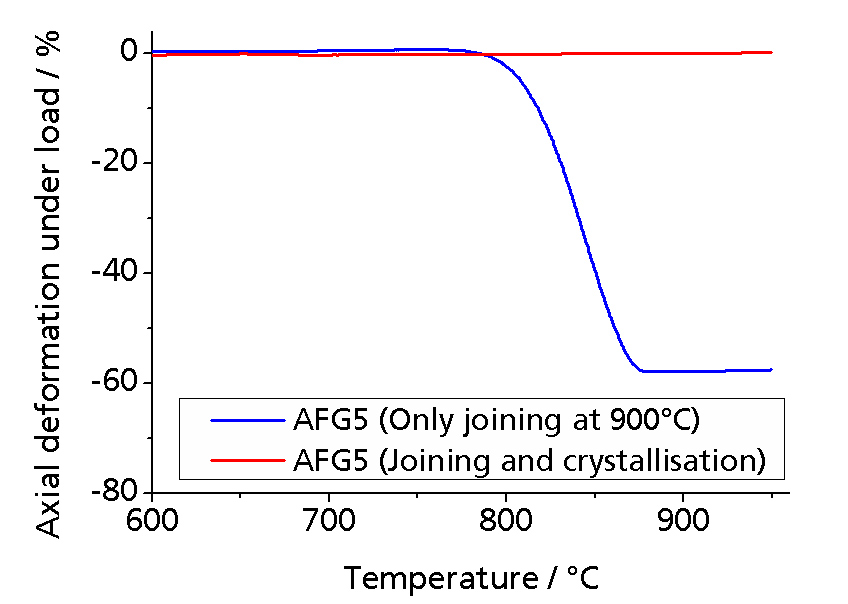

Deformation of a crystallizing glass solder for HTCC-multilayer (Al2O3) under axial load after joining at 900°C and crystallisation at 850°C

HTCC multilayer technologies allow the assembling of ceramic components like micro reactors or sensors for high temperature applications up to 1000°C. Often functional elements like catalytic active layers or thick film structures with limited temperature stability are additionally integrated in these components. As a consequence for the packaging of HTCC components crystallizing solder glasses adapted for firing profiles with peak temperatures below 1000°C are required. Under operating conditions these glass-ceramics provide hermetic seals and offer a good stability against mechanic load.

|

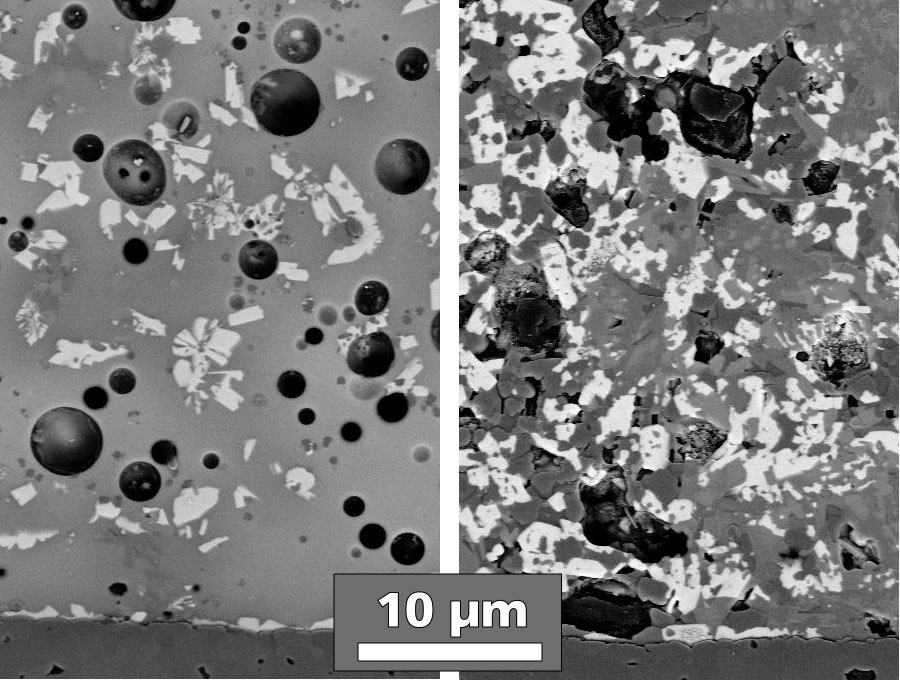

| SEM-images of crystallized glass solder direct after joining procedure and after joining and crystallization |