In industrial processes and plants, measurement of various parameters and quantities at high temperatures in corrosive environments by means of sensors is necessary for optimal process control. Sensors based on ceramic materials are becoming increasingly important because of their ability to be used at very high temperatures in aggressive liquid as well as gaseous environments.

In addition to ceramic sensors for measurement of temperature and chemical parameters, especially the measure of pressure, force, flow, and position sensors, occupying about onethird of the market volume for sensors, are being increasingly targeted as a market for ceramic materials. Integration of ceramic sensors represents a challenge due to the need for a hermetically sealed, thermally stable, corrosion-resistant, and lowstress metal-ceramic composite designs for the implementation of ready-to-use standard housings and connections for end users.

In order to meet these challenging joining tasks, Fraunhofer IKTS can develop and adapt the compositions of solder glasses to properties, such as softening behavior, coefficient of thermal expansion, corrosion stability, and compatibility with ceramic and metal joining partners. Furthermore, the processing of glass frits to form powders with defined properties and their transfer to ready-to-use slurries, pastes, and cast tapes offer flexible technological solutions.

Active metal brazing (AMB) technology based on metal alloys provides reliable and thermally stable metal-to-ceramic joints. Joining processes using active metal brazes have been developed at Fraunhofer IKTS not only for sensor applications but also for thermoelectric modules, fuel cells (SOFCs), high-temperature batteries (ZEBRA) and structural ceramic components. With simulation-assisted component design, ceramic-compatible joints can be realized.

These joining technologies can be combined to yield adjusted multistage joining processes for process capability, reliable thermal loading of components, and thermomechanical stressfree integration of ceramic sensor elements into ceramic as well as metal housings and connections.

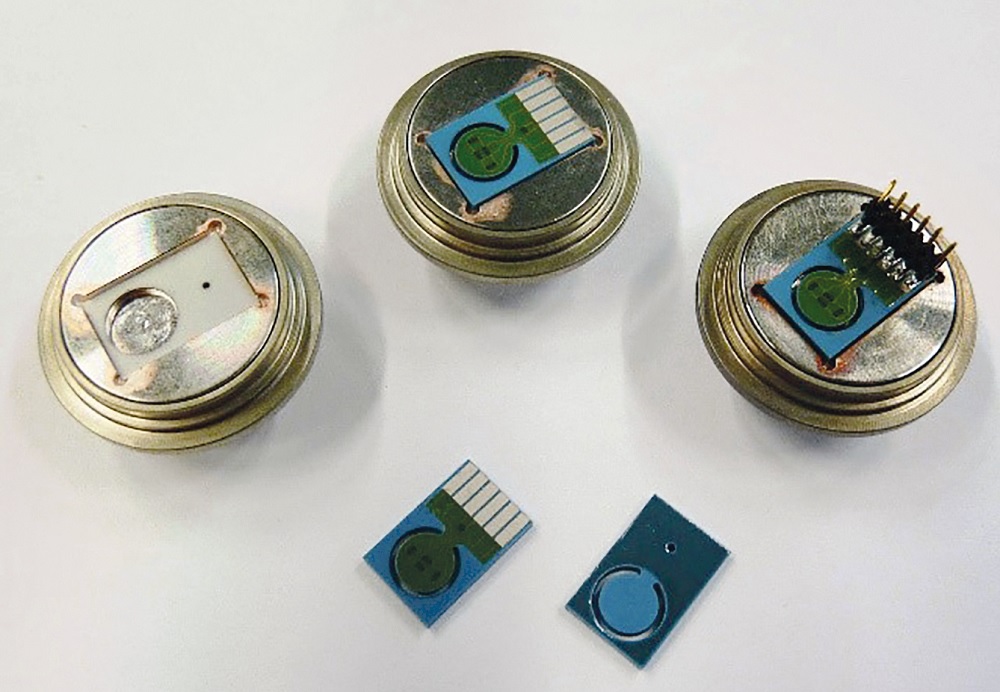

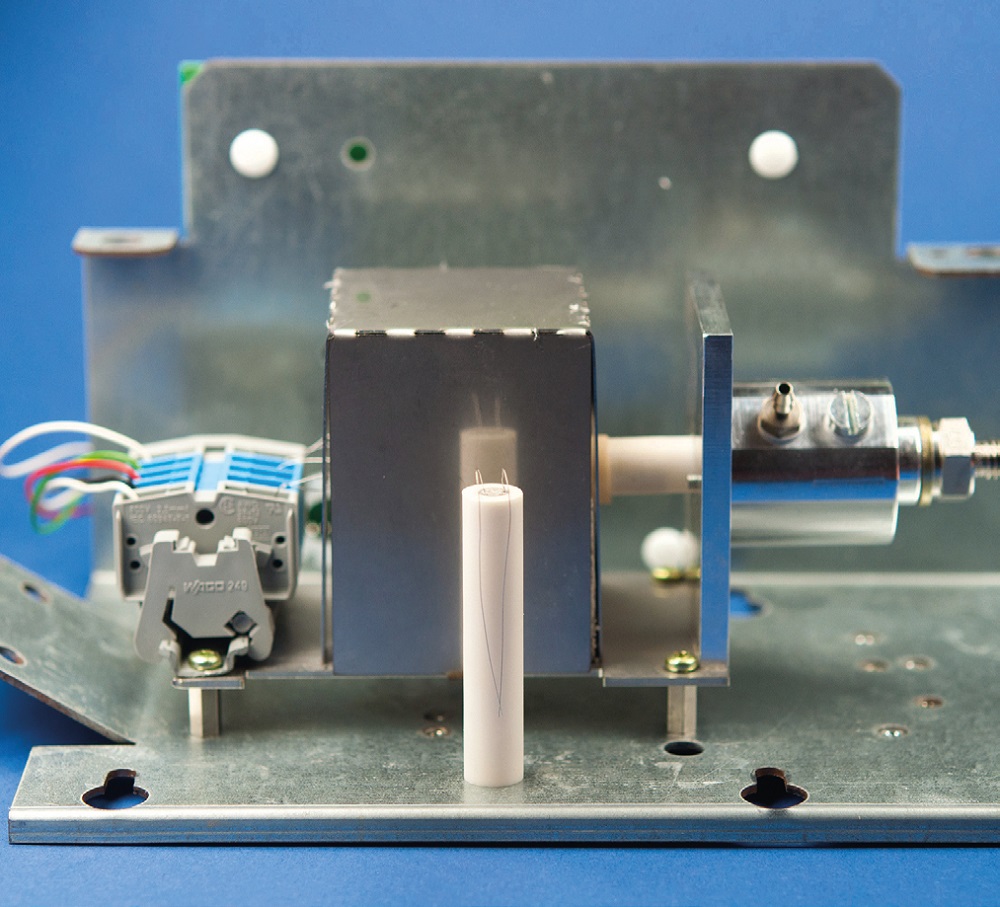

Selected examples illustrate the possibilities for different sensor types. Glass-ceramic solders from SOFC technology were adapted to join ZrO2-based oxygen sensors (400 °C to 800 °C) (Figure 2). Miniaturized semiconductor technology-based MEMS sensor elements bonded to ceramic bodies with low-melting glass solders enable the measurement of pressure and acceleration in attitude sensors up to 160 °C. LTCC-based pressure sensors were integrated into standard steel threaded and bayonet connections for measurements up to 250 bar at 300 °C via a three-stage joining process using brazes, active filler metals, and glass solders (Figure 1). Glass solders with optimized corrosion resistance extend the application ranges of capacitive pressure sensors made of Al2O3 ceramics in extremely corrosive liquid media to 150 °C and 180 bar.