Thin-film photovoltaics on technical textiles – PhotoTex

Current research

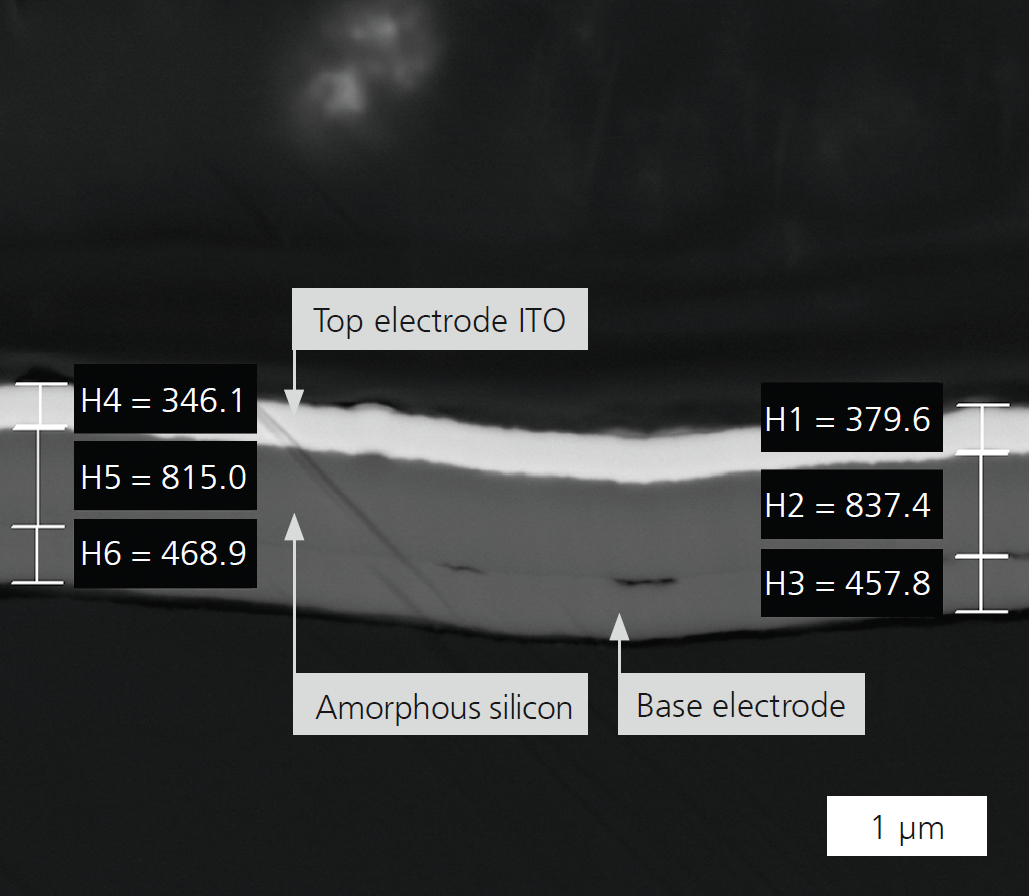

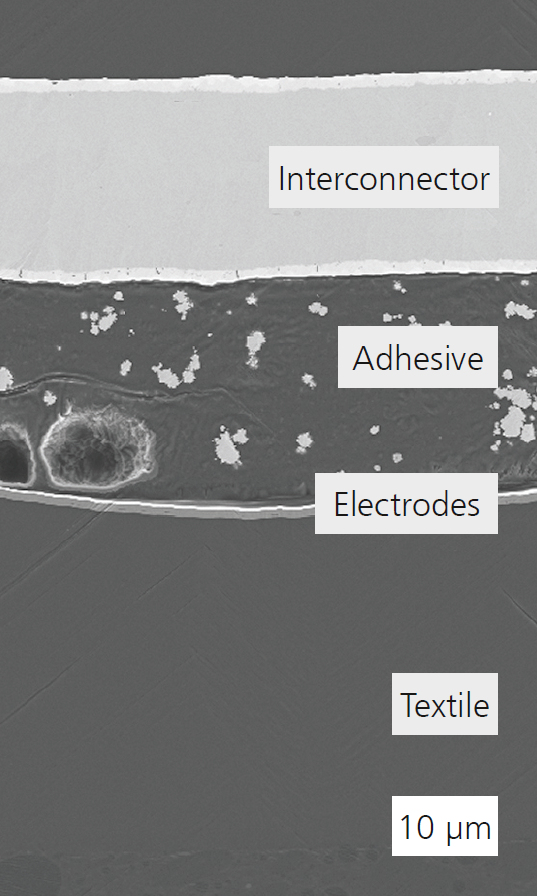

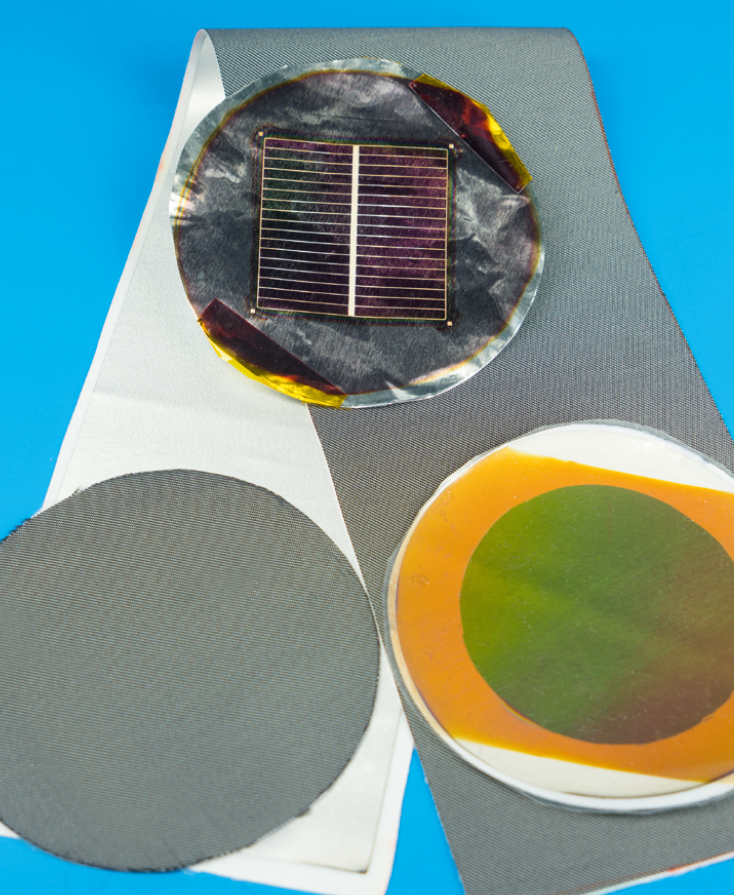

In the future, marquees, slats and sun sails may not only protect against the sun, but also generate solar power. This power can be used for the energy-autonomous control of the marquee, and for many other things. As part of the “PhotoTex” project, Fraunhofer IKTS is working with partners to equip, for the first time, flexible technical textiles with practical photovoltaic layers. This is done by combining thin- and thick-film technologies with textile technology. The goal is to develop and validate different photovoltaic coating systems, which are applied to textile substrates using different processes. A prerequisite for the uniform application of thin-film solar cells on the rough textile surfaces, besides pretreating the substrate, is a base coating of the textiles. In a first step, textiles and compensating materials need to be found whose temperature behavior is compatible with thin-film technologies. To build up the layers, electrically conductive base electrodes made of aluminum and molybdenum were sputtered onto the leveling layers using DC magnetron sputtering. An electrode layer made of aluminum film laminations proved even more efficient. Photovoltaic active layers consisting of amorphous silicon layers were generated using PECVD. An indium tin oxide (ITO) layer generates the electrically conductive top electrode. Electrical conductive polymers were screen-printed on the ITO layer as interconnection areas. The latter are of particular importance as mounting levels for power tapping. Soldering processes at low temperatures, conductive adhesives and connection solutions using rivets were investigated as interconnection technologies compatible with textile industry standards. Additionally, masking technology had to be developed to minimize shorts and shunts between the electrical conductive hybrid layers. Finally, hermetic sealing using a film lamination process facilitates a stable, long-term operation. Trials and prototypes have shown that the production of technical textiles with photovoltaic active thin-film layers is possible. To assess efficiency and long-term stability, a small batch with active photovoltaic areas of up to 250 mm² per system was produced. All modules show an efficiency between 0.1 and 0.3 % under AM 1.5 sun spectrum. The project members believe that an efficiency increase of up to 2–5 % is realistic as the basic concept is developed further. This makes the economically viable use of solar-active sun protection-textiles a real possibility in the near future.

We gratefully acknowledge the German Federal Ministry of Education and Research BMBF for funding the project “PhotoTex” (funding reference 03ZZ0614A).

Services offered

- Development and validation of functional layers on textiles

- Development and realization of packaging technologies

- Realization and characterization of small-batch production