Sustainable electronics: evaluation of the degradation of mold material for power electronics

Current research

Reliability by protection of electronics

Sustainability is achieved through the reliable longevity of products. In power electronics this is achieved by protecting vulnerable components using isolating encapsulation materials. There are strict requirements for these materials, which depend on extrinsic (environmental conditions) and intrinsic (operating parameters) factors. Power electronics are used especially in electromobility, industrial electronics, and power engineering.

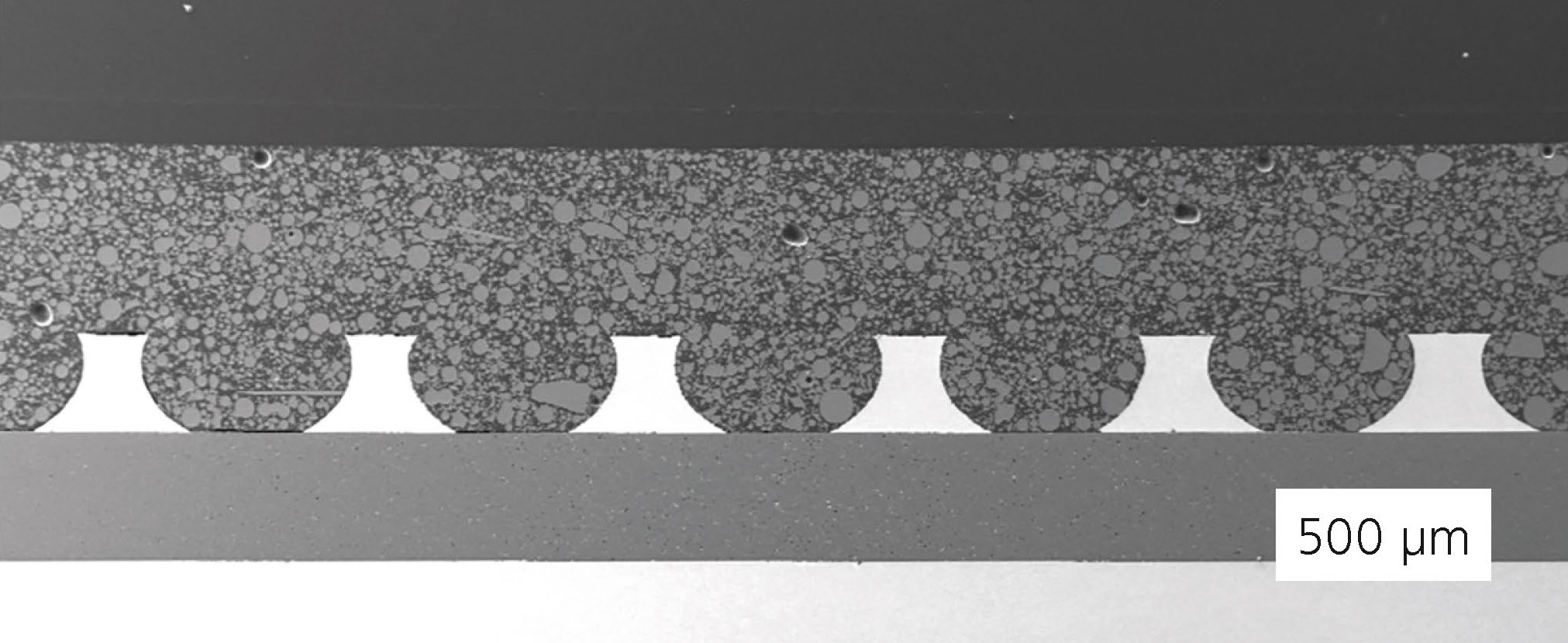

Under harsh conditions (e.g. offshore) the reliability of the active components requires high-quality encapsulating materials, which are also readily available, cost-effective and easy to process. Because they are safety-relevant for high electric currents, these materials must be stable in the long term. Currently, a composite of highly filled epoxy polymer (EMC), which encapsulates power electronics via thermal transfer molding, is most promising.

Detailed knowledge of their degradation mechanisms and kinetics is critical for the reliability and lifetime of power electronic devices.

A novel approach to the characterization of materials

In the past, optical and mechanical methods were frequently used as test methods for the investigation of encapsulations. However, highly filled epoxy mold compounds are optically non-transparent and mechanical tests are destructive.

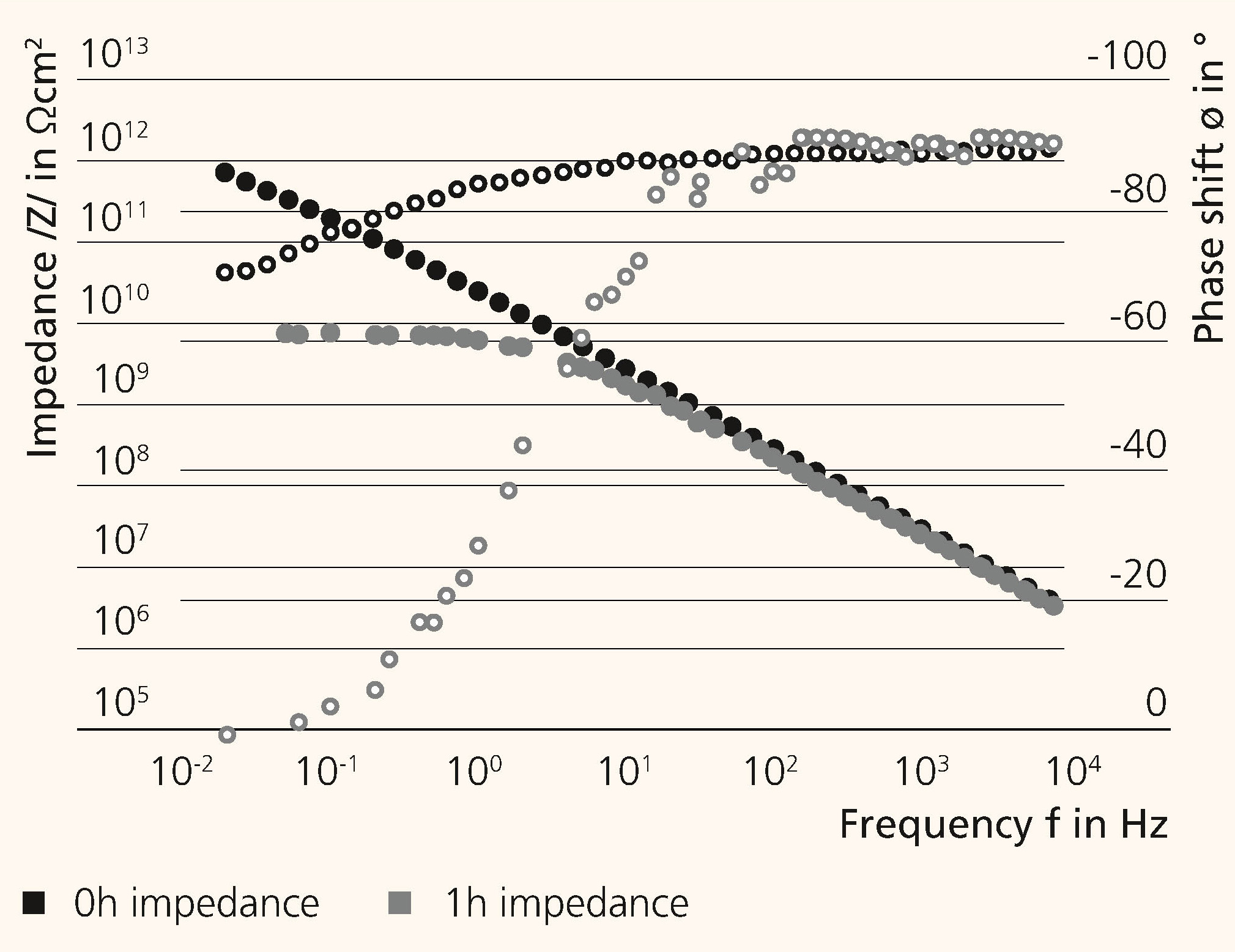

Impedance spectroscopy is an alternative non-destructive test method. The use of so-called electrical equivalent circuits makes it possible to interpret the measured spectra as a temporary degradation condition. The degradation kinetics can be determined from the time-dependent repetition of the measurements (monitoring) and, with certain limitations, lifetime predictions become possible.

The high specific resistance of the encapsulation and the miniaturized structures available for measurement require precise current signal detection in the pico-ampere range. To realize this, the joint project “TTM-Process Reliability” develops high-impedance measuring devices and setups with sufficient shielding while defining industrially transferable parameters.

Image 2 shows exemplarily impedance spectra of EMC-encapsulated copper substrates before (0 h) and after one hour (1 h) of exposure under multiple stressors consisting of temperature, pressure, and humidity. The frequency-dependent changes in the impedance spectra impressively reflect the degradation process of the loaded encapsulation material and illustrate that impedance spectroscopy is very well-suited for the non-destructive evaluation of encapsulation materials.

Supported by