Energy

Areas of application

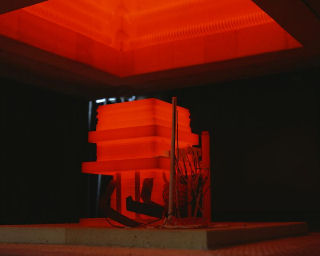

Energy storage

Fraunhofer IKTS is working on lithium-ion batteries and their production methods as well as batteries based on ceramic sodium solid-state ion conductors for cost-effective decentralized energy storage solutions. In particular, the work with batteries using solid-state electrolytes and composite materials based on solid-state ion conductors is unique in this area. Other focal points are metal-air batteries and supercapacitors. The available heat storage media are based on zeolites, phase change materials and components for salt storage systems. The research topics cover the complete value chain for energy storage systems and their manufacturing, from the lab to production scale.

Related Links

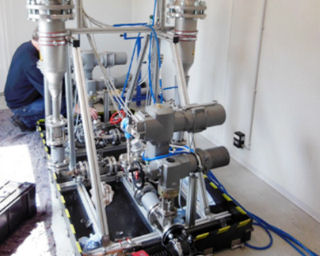

Electrolysis and Power-to-X

The electrolysis of water steam and CO2 at the commercial scale is a key technology for using excess electrical energy from renewable sources. For instance, the energy can be converted to fuels and chemicals, such as hydrogen to be introduced into gas networks and then reconverted into electricity, or transformed into higher value hydrocarbons by conversion with CO2 via synthesis gas. The fuel cell stacks of Fraunhofer IKTS are ideal for electrolysis operation. Our experience in the development of cells, interconnectors and joining methods, gained in our work with commercial SOFC technology, enables rapid design and material iterations as well as largescale modules. Furthermore, Fraunhofer IKTS is working to develop reactor concepts. The institute combines water selective membranes with catalytic converters in the membrane reactor or membrane contactor. Furthermore, our researchers develop catalytic converter systems and engineer processes, methods and plants for the production of fuels and chemicals using the Fischer-Tropsch synthesis.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyPower-to-X Technologies at Fraunhofer IKTS.

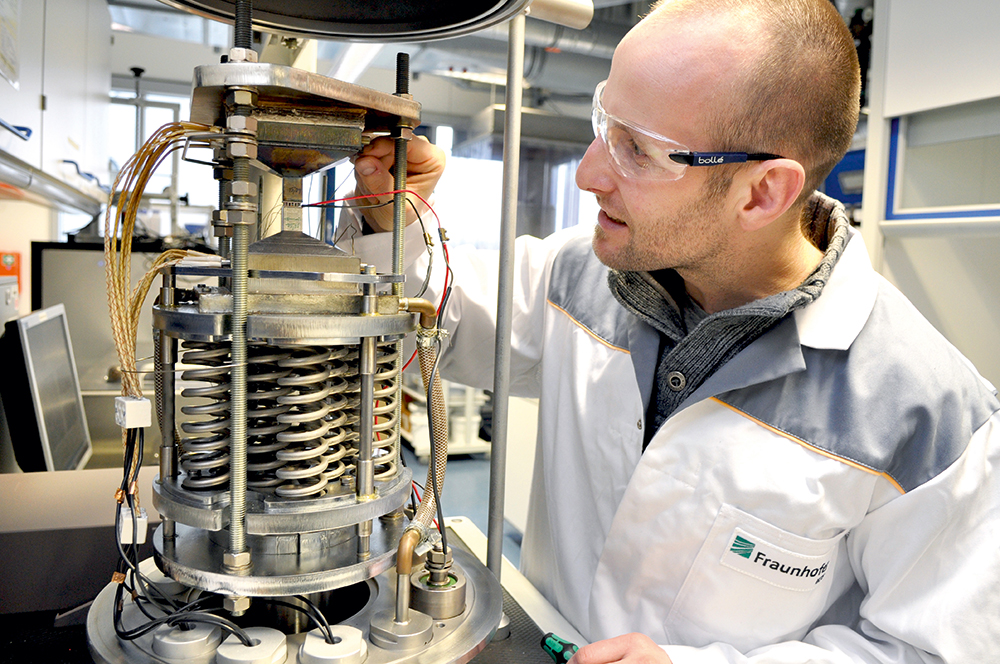

Fuel cells

Producing electricity with SOFCs and MCFCs is in its first stage of market introduction. New production methods are investigated for PEM fuel cells with the aim of reducing the platinum content. Other efforts focus on the consistent reduction of manufacturing costs, extending service life, increasing the number of usable fuel types, and on system integration. The IKTS is a leading international partner with decades of experience. Its capabilities cover the full value chain: The IKTS develops cells and stacks, manufactures these on the prototype scale and integrates them in client-specific systems through modular methods, in order to demonstrate compact and energy-efficient solutions for the cogeneration of heat and power. The performance range of such systems includes portable devices in the 50 W range, as well as stationary plants in the MW range. The most varied fuels are used for these systems, such as biogas, LPG and hydrogen.

Related Links

Bioenergy

The IKTS supplies a large number of process engineering solutions for bioenergy technologies, such as disintegration, mixing and stirring processes. For the treatment of biogas, adsorptive and membrane methods are used to optimize the processes for methane enrichment, gas dehydration, nutrient recovery and process water treatment. The focus is on making biogas plants more flexible in responding to fluctuations in energy demand. Furthermore, bioethanol manufacturing processes are improved through membranes at various points in the production process, e.g. during saccharification, dewatering or substrate treatment. Novel organophile pervaporation membranes and ultrafiltration membranes help to make production processes more efficient.

Related Links

Deep geothermics

In deep geothermal plants, extreme conditions, such as high pressures, temperatures and salt content, often cause corrosion and incrustation, affecting their economic viability and operational safety. Based on its long years of experience with incrustation phenomena and its excellent analytical equipment, Fraunhofer IKTS also focuses on developing corrosion-resistant components and plants, and on process design. Experimental and corrosion testing rigs enable real-time on-site monitoring. Electrochemical treatment of the thermal fluids allows toxic substances and geogenic radionuclides to be retained and disposal problems to be avoided. During this process the recovery of strategically important metals is also possible.

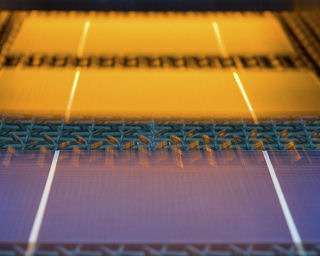

Photovoltaics and concentrated solar power

The efficiency of solar cells depends to a large degree on the electric conductivity provided by the metal collector electrodes. Highly efficient thick-film and direct-write techniques enable the cost-efficient metallization of cells. Fraunhofer IKTS develops pastes and inks for existing and novel cell concepts. In the field of concentrated solar power (CSP), Fraunhofer IKTS is working on receiver materials and high-temperature materials for heat exchangers and heat storage systems. The integration of thermal energy storage solutions makes it possible to provide energy when it is needed.

Energy harvesting

For energy supply of decentralized microsystems, such as sensors or medical or consumer devices, it is possible to use energy from the environment such as waste heat or vibration. Based on long years of experience with ceramic active materials (thermoelectric and piezoceramic materials), the Fraunhofer IKTS researchers are developing so-called energy harvesters, e.g. piezo and thermoelectric generators.

Related Links

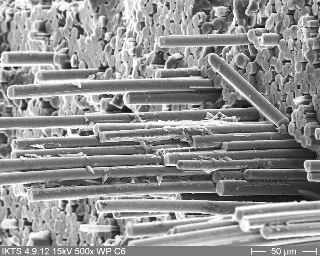

High-temperature gas turbines and thermal energy systems

Increasing the eco-friendliness and efficiency of hot gas turbines and reducing emissions requires higher process temperatures, and therefore materials with high thermal shock resistance. Therefore, monolithic ceramics and ceramic matrix composites (CMC) are an interesting alternative to metals. Beyond this, Fraunhofer IKTS also focuses on environmental barrier coatings based on oxide and non-oxide ceramic systems.