Sealing ceramic fiber composites with laser technology

Current research

Oxide ceramic matrix composites (OCMC) are materials with excellent high-temperature stability up to approx. 1200 °C and damage-tolerant behavior. Furthermore, these materials are characterized by a high chemical resistance in many media and a low density. For this reason, the OCMC materials are well suited for demanding applications in combustion technology (gas turbines, engines, burners), in the heat treatment of steel (charging racks, baskets) and the chemical industry (reactors, heat exchangers, swirlers).

Pores as show stoppers for many applications

In order for the material to retain its damagetolerant properties, it needs to be porous. This, however allows liquids and gases to enter or pass through the material. In addition, the pores make the material susceptible to wear.

Why not just coat it?

Common coating processes, such as plasma spraying, allow OCMC to be sealed. However, under mechanical stress or thermal shock, such coatings tend to crack or flake off. This severely limits the service life of the component.

Coating adhesion by laser radiation

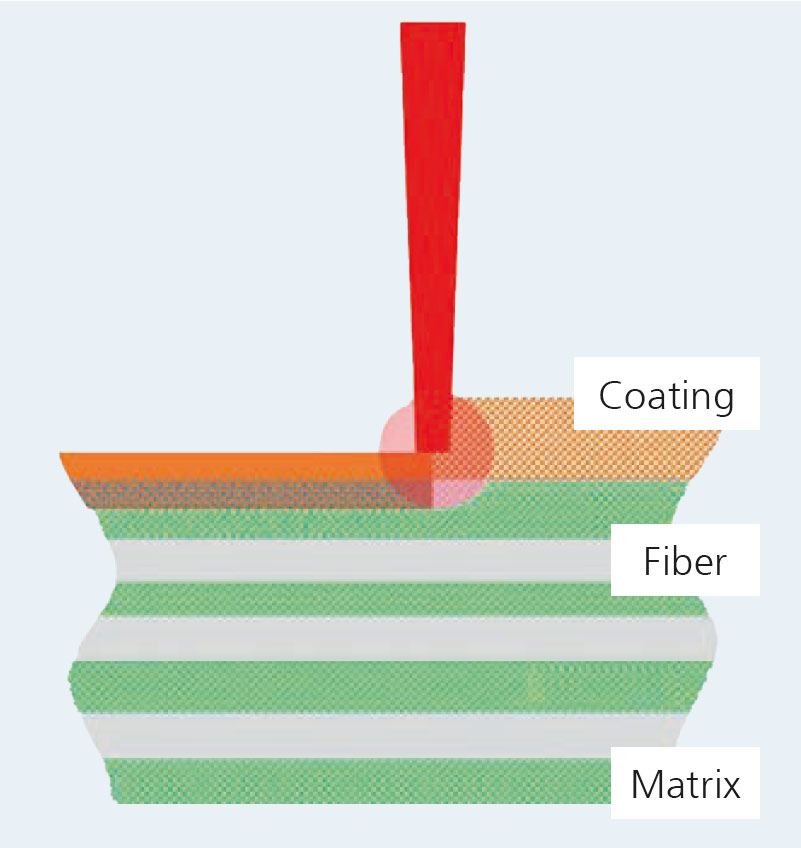

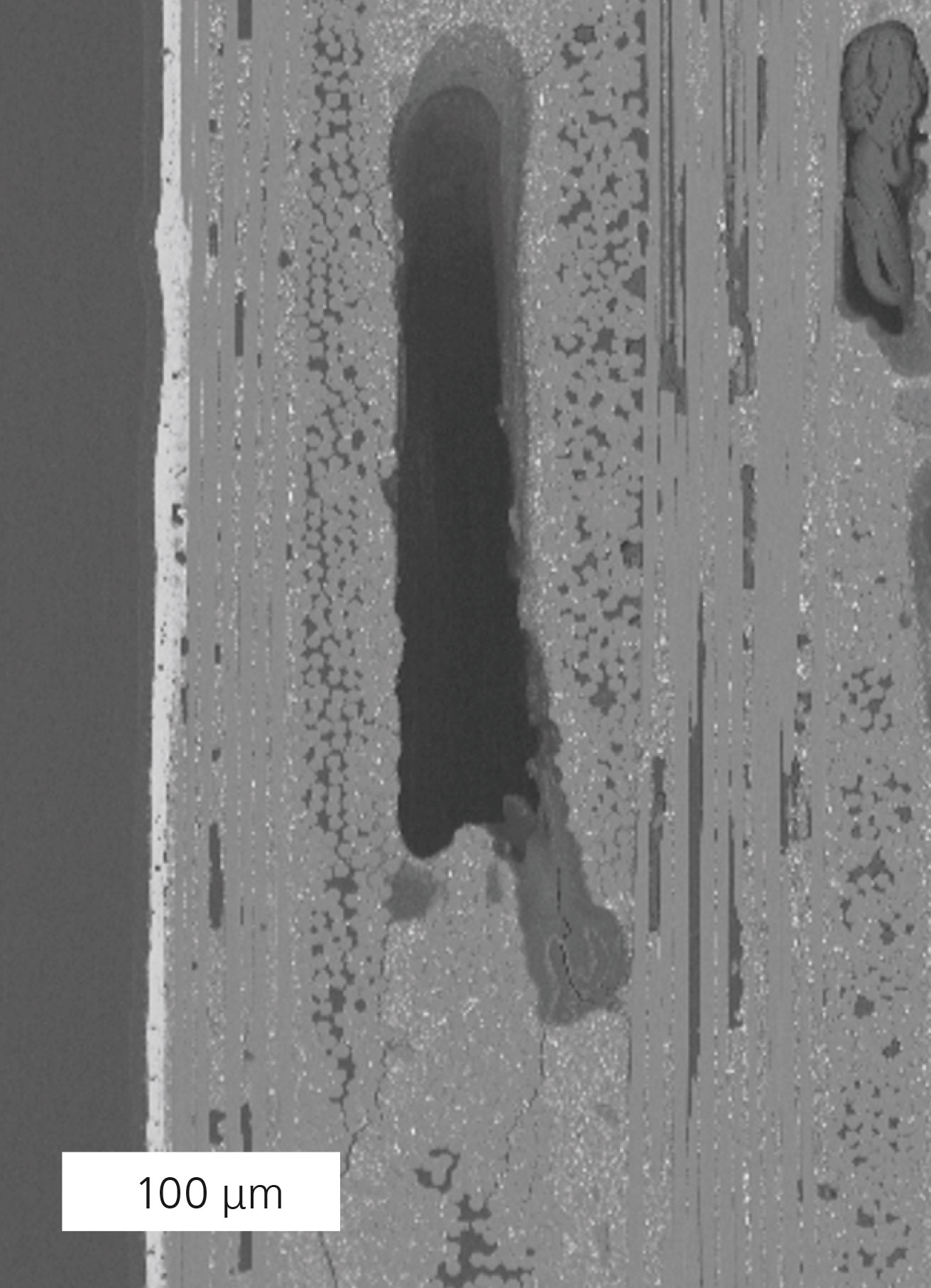

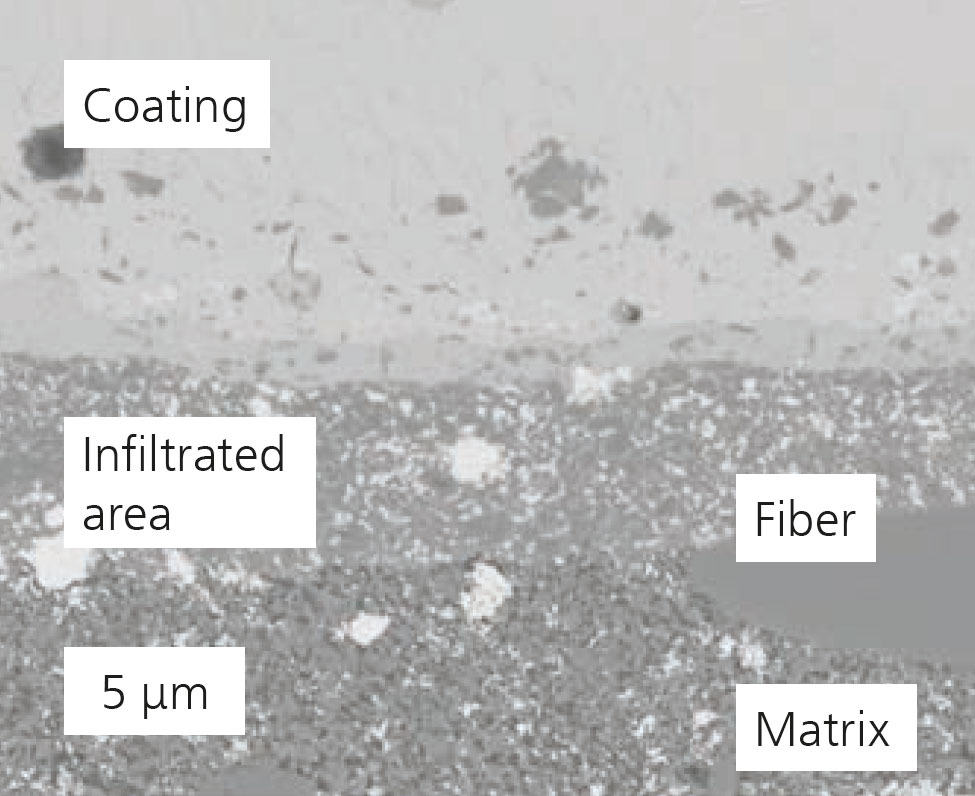

To improve the durability of the coating, Fraunhofer IKTS is currently developing a new coating process: By means of laser radiation, a ceramic powder applied to the surface is melted, and the surface of the OCMC infiltrated.

The coating material does not just lie on the surface, it also bonds with the base material. This significantly improves the adhesion of the coating and seals the material.

The new approach uses a special physical principle, which is used to heat up and melt the high-temperature-resistant coating materials locally without overheating the component.

A micro-optically optimized diode laser array that delivers a line-shaped focused beam (Focuslight/LIMO GmbH) serves as a cost-efficient laser source. It enables fast processing of larger areas and ensures higher energy efficiency compared with conventional lasers with a point-shaped focused beam.

In parallel, IKTS is working on quantifying the component properties of such sealed OCMC (tightness, strength, etc.).

Services offered

- Surface sealing: liquids and gases no longer penetrate the material. Pressure differences can exist without mass transport through the material.

- Adaptation of the coating system to the application: Corrosion or abrasion? The choice of the appropriate coating material is decisive.

- Measurement and evaluation of material properties: investigation of thermal and corrosive resistance as well as microstructure and mechanical properties.