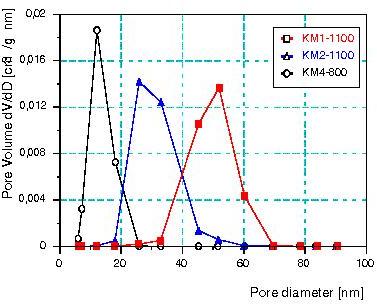

Pore size distribution in mesoporous corundum (temperature of calcination see insert, open porosity of examples about 45 %).

Highly porous corundum ceramics with average pore sizes between 10 and > 100 nm

Selected modifications of the IKTS-synthesis of NanoCorundum give mesoporous corundum products for filtration, catalyst and sensor applications, manufactured optionally by sol/gel or powder technical approaches.

Advantages

- Improved chemical and thermal stability of corundum compared with transitional alumina phases avoiding slitshaped pores of high tortuosity

- Common, inexpensive raw materials (Al-nitrate) for controlled hydrolysis

- Options: Powder technology enabling a leap to a new quality by avoiding flaws; Sol/gel synthesis

- Controlled hydrolysis: transformation to Nanocorundum completed at low temperatures >750°C * high open porosity of the products (45-55 %)

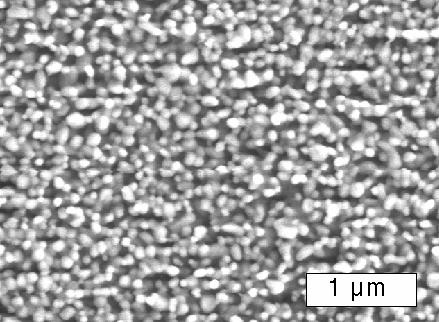

- Inexpensive options: use of commercial powders/sols * open porosity 40 % with same pore size/α-Al2O3

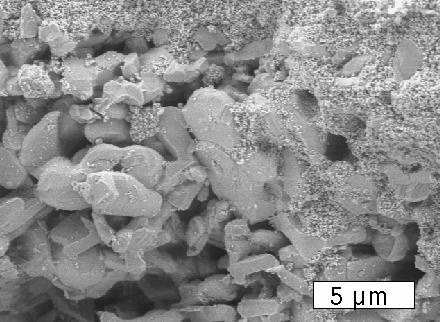

- Coarser pores up to about 200 nm (sol/gel) and more (powder technology)

- High biaxial strength of coarser microstructures: 80-100 MPa at pore size 150-200 nm/porosity 40-45 %

Products and services offered

- Development of technologies for mesoporous corundum products

- Development of optimized materials for specific applications

- Upscaling investigations supporting the development of new products

- Investigations of the technical performance (e.g. penetration, deposition on different substrates [e.g. metals])