Homogeneous porous Al2O3 components with pores > 1 µm

Corundum (α-Al2O3) is a premium material for applications in corrosive media or at higher temperature, preferentially avoiding or with a minimum of glassy binders. However, with bigger particles it becomes increasingly difficult to obtain a sufficient strength by pure solid state sintering.

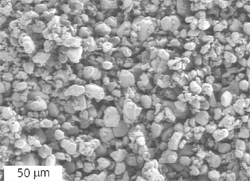

Homogeneous microstructures may contribute to a solution of this difficulty, e.g. by means of wet shaping approaches as gelcasting. Because of sedimentation problems such casting processes are commonly limited to the processing of finer particles - a problem that was overcome here by the use of modified polysaccarides (e.g. agarose) as gelling agents with tunable viscosity. Fig. 1 shows tubes (∅ 1 cm) manufactured by this approach from a corundum powder with 14 µm particle size (-> pore size ≈ 4 µm), Fig. 2 displays a sintered microstructure

Corundum (α-Al2O3) is a premium material for applications in corrosive media or at higher temperature, preferentially avoiding or with a minimum of glassy binders. However, with bigger particles it becomes increasingly difficult to obtain a sufficient strength by pure solid state sintering.

Homogeneous microstructures may contribute to a solution of this difficulty, e.g. by means of wet shaping approaches as gelcasting. Because of sedimentation problems such casting processes are commonly limited to the processing of finer particles - a problem that was overcome here by the use of modified polysaccarides (e.g. agarose) as gelling agents with tunable viscosity. Fig. 1 shows tubes (∅ 1 cm) manufactured by this approach from a corundum powder with 14 µm particle size (-> pore size ≈ 4 µm), Fig. 2 displays a sintered microstructure

Advantages

- Simple process with low organic additive, applicable for different ceramic materials; High strength of green bodies

- Manufacture of porous components with larger pores from one raw powder (e.g. corundum) as from mixtures of different components (e.g. with an additive of a finer binder phase)

Products and services offered

- Development of manufacturing processes for compact porous components with defined pore structure, chemical, thermal and mechanical properties

- Upscaling investigations supporting the development of new products in different fields as e.g. filtration, catalysis, grinding tools

- Investigation of the technical performance on application