Based on enormous growth rates, achieved for integration densities of semiconductor elements at chip level in the last years, there is an increasing demand to transfer this trend of miniaturization and extension of functions to the next integration level, i.e. to microelectronic devices and systems. In most cases passive elements, such as capacitors, are a limiting factor of this development as – due to their dimension – they mainly determine the energy density of an assembly or system particularly in the field of power electronics.

As the energy density of a capacitor is primarily determined by the permittivity of the dielectric material there is an increasing demand for highly dielectric materials which can be co-sintered with inexpensive electrode materials such as silver at temperatures below 950°C. The development of low-sintering highly dielectric materials is in the focus of current research. In this connection we have many years of experience in:Aufbereitung hoch dielektrischer Pulver auf Basis von BaTiO3

- Preparation of high-k powders based on BaTiO3

- Evaluation of sintering additives to reduce the sintering temperature of BaTiO3 powders

- Development of low-loss dielectrics

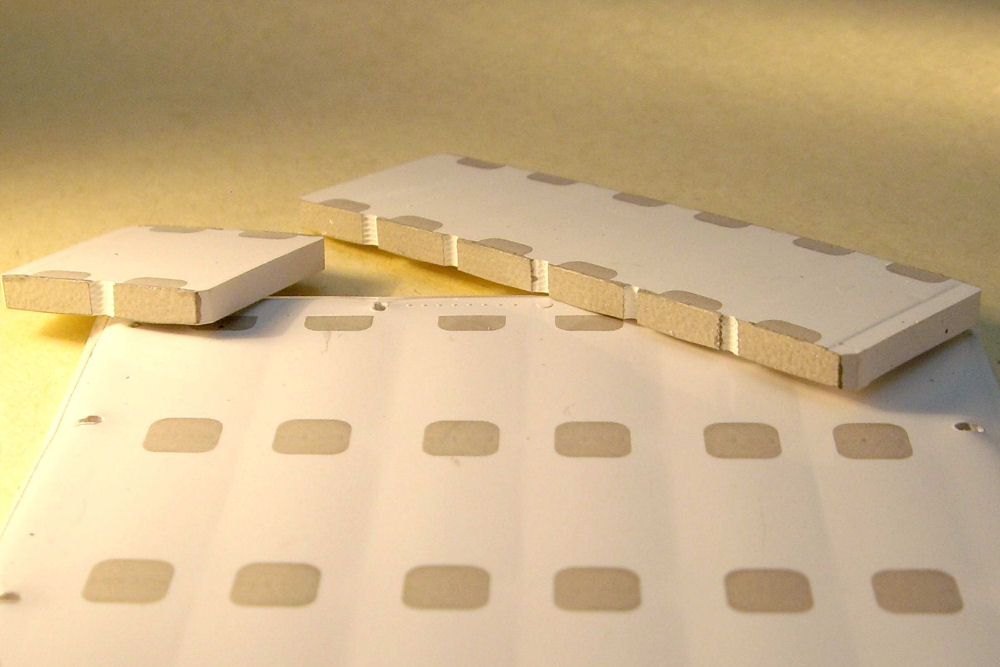

- Development of green high-k tapes

- Shaping of complex bodies

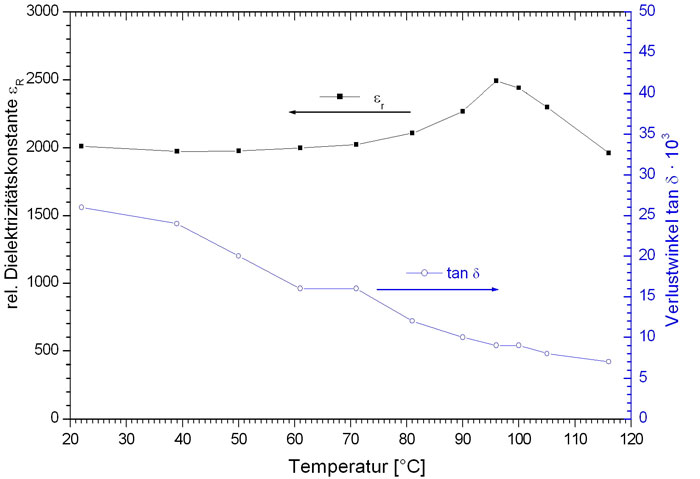

- Characterization of dielectric materials

Services offered

- Development of dielectric materials

- Development of green high-k tapes

- Development of shaping technologies for dielectric powders

- Metallization of dielectric test specimen

- Measurement of basic dielectric material parameters such as permittivity and loss

Technical equipment

- Various grinding aggregates for fine-grinding of dielectric powders

- Tape caster for dielectric tapes

- Various sintering furnaces

- Test site for the determination of dielectric material parameters

Examples and references

- Highly dielectric material with a permittivity > 2000

- Pb-free X7R material with a sintering temperature of 900°C

- High-k tapes with thicknesses of < 40 µm

- Ceramic multilayer capacitors with silver inner electrodes