Luminescent material-based composites for lighting technology

Current research

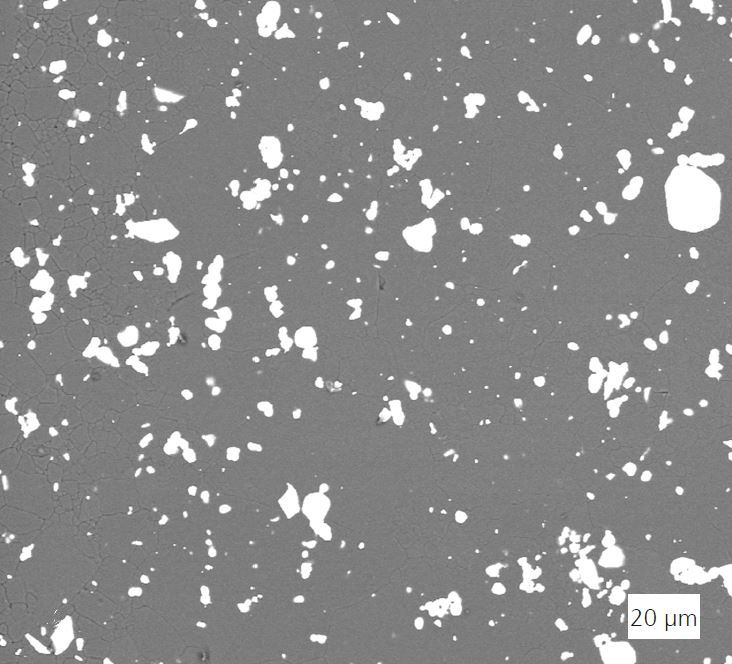

Light-emitting diodes (LEDs) with high power densities are currently revolutionizing nearly all areas of lighting technology due to their outstanding performance characteristics, such as light output and service life. Unlike conventional incandescent or halogen light bulbs, LEDs can only emit colored light over a very narrow range of wavelengths because of their underlying excitation mechanisms. For color perception reasons, general lighting applications normally use white light, which has a spectral composition largely approximating that of a thermal radiator to achieve good color rendering properties. The colored light of an LED must hence be converted to white light. Suitable converter phosphors that, due to electron excitation processes, absorb light at short wavelengths and emit the incoming energy in the form of light at longer wavelengths are used for this. For reproduction of all of the colors in the visible light spectrum, blue light is converted to white light with a yellow phosphor or a phosphor mixture. The phosphor is incorporated into a transparent binder matrix made of silicone or siloxane resin, applied as a paste to the LED chip, and thermally cured. With increasing LED power density, especially in the case of high-power LEDs, the phosphor and the organic binder matrix are subjected to increasingly high thermal and UV radiation loads, which affect both service life and quantum yield of the converter. With innovative converter materials in which the phosphor is either embedded in a transparent ceramic carrier material with high thermal and UV stability or applied to glasses or transparent ceramic substrates via a ceramic thick-film process, these disadvantages can be avoided and the stability and service life of these white light converters significantly improved.

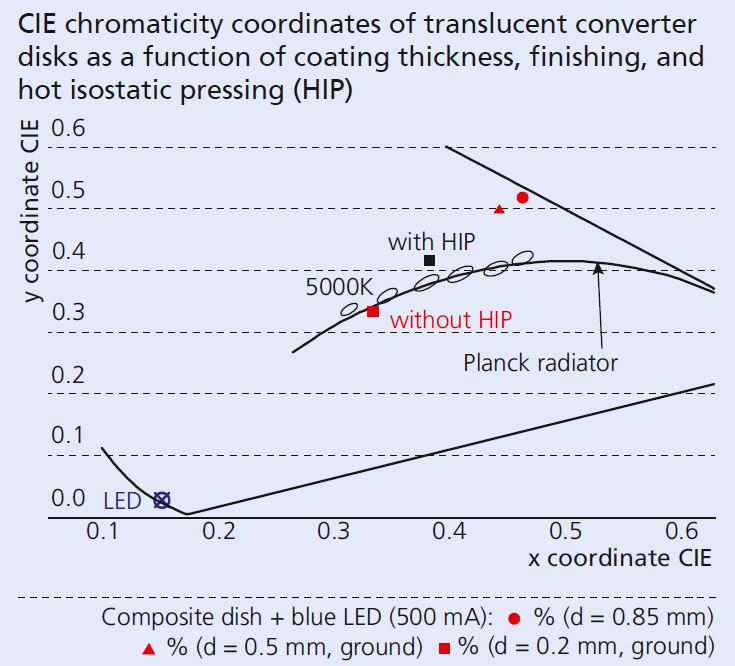

Both through the implementation of luminescent YAG:Ce3+ materials in a transparent spinel matrix and with the help of glass-ceramic YAG:Ce3+ thick films, translucent converter disks that can be combined with a blue LED to achieve the white light curve in the CIE diagram can be fabricated. The outstanding thermomechanical properties of these converter disks predestine them for use in high-power LEDs.

Supported by