Tape casting can be used in a novel way to manufacture metalceramic composites with high process and resource utilization efficiency. This process, which includes the conventional sintering process, can be used with a wide range of products, especially steel-zirconia composites. The combination of Crofer 22 APU and zirconia is employed in fuel cell technology, a field in which Fraunhofer IKTS researchers are among the leaders. This material combination can also be applied in the manufacturing of hightemperature filter systems, membranes for gas separation, and tooling equipment.

The second group of suitable materials is the combination of zirconia with high-alloy 17-4 PH steel, commonly known as “surgical steel“. These composites can be interesting alternatives for typical surgical instruments, such as bipolar scissors, grippers, and tweezers (Figure 1).

The properties of these products can only be improved when an understanding of the behavior of the incorporated materials at the microscale and the nanoscale is given. A key enabler for the further development of co-sintered steel-ceramic composites is knowledge of the mechanical, chemical, and long-term properties. The established characterization methods (optical and scanning electron microscopy) must be supplemented with imaging and analytical transmission electron microscopy (TEM). This requires the development of a proper method for preparation based on the focused ion beam technique (FIB).

The first experiments were focused on the application of a liftout preparation technique at the boundary between steel and ceramics using the experience gained from other categories of materials.

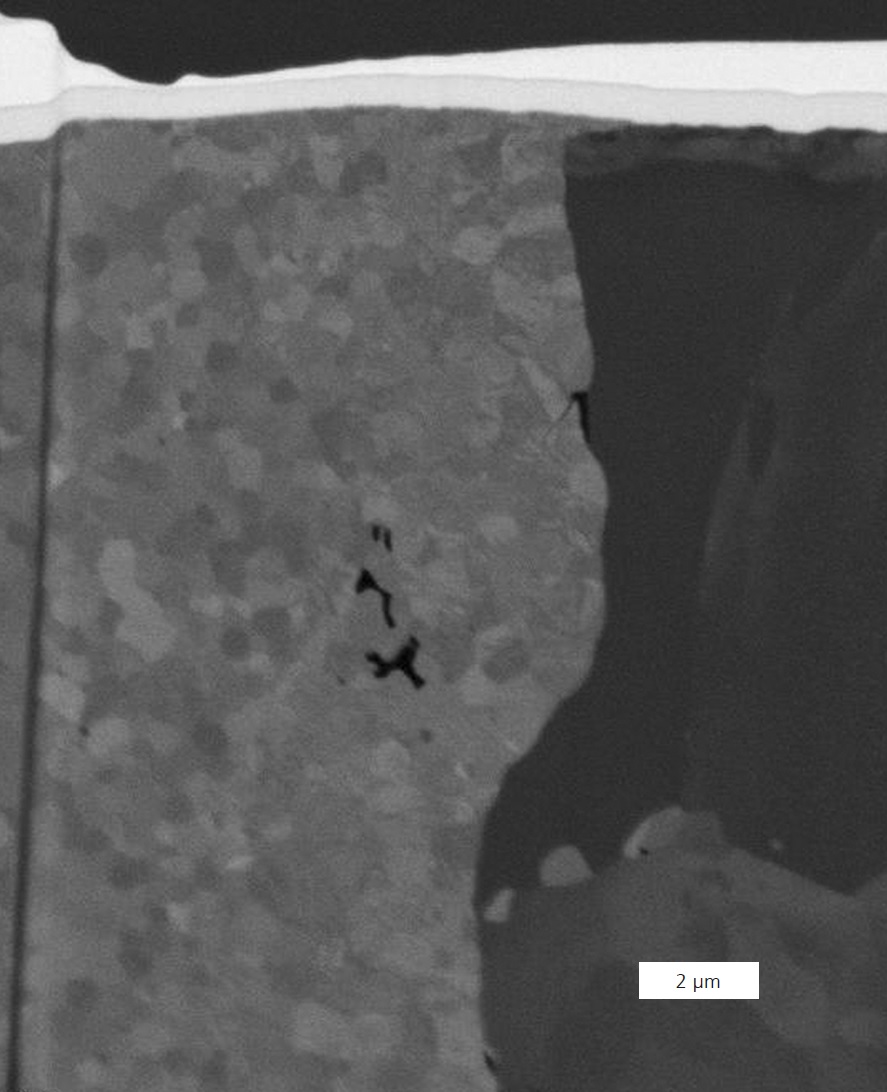

This preparation technique was successfully used with various combinations of materials, especially densly sintered materials (Figure 2). The stability and feasibility of porous materials were achieved through infiltration with an epoxy material and subsequent curing.

Energy-dispersive X-ray spectroscopy (EDX) in the TEM was mainly used for elemental analysis. Crystallographic structures were investigated using electron diffraction. For both applications, the thickness of the TEM foil was maintained above a minimum value for ensuring the robustness of the specimen.

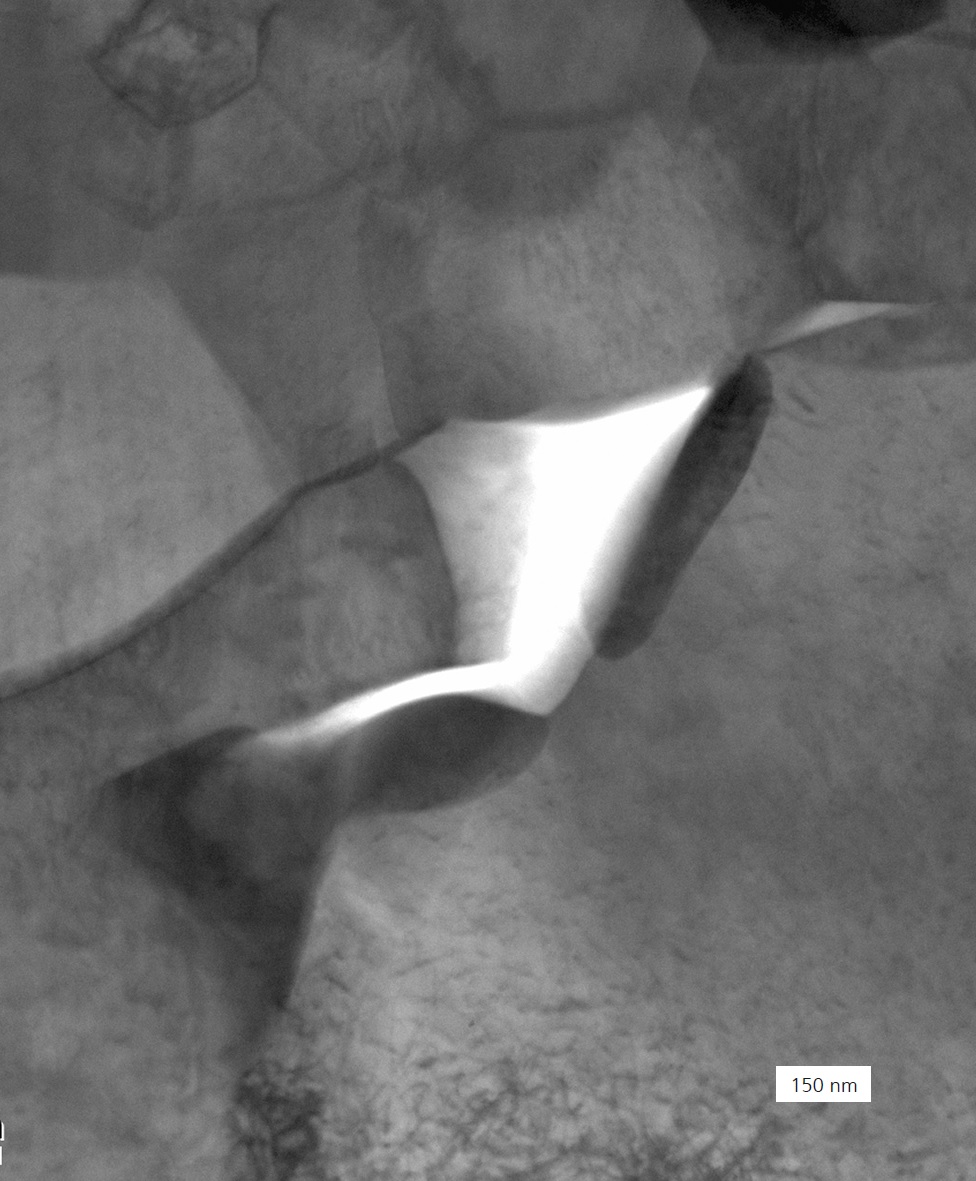

The scanning TEM (STEM) was operated in bright field mode to give the best results due to the high beam intensity used (Figure 3). In this mode, EDX spectra and elemental mappings of regions of interest were obtained. The alloying elements in the steel formed precipitations of oxidic nature at the interface between the steel and the ceramic layer. The effect of these precipitations on the mechanical behavior and under corrosion conditions will be the subject of further investigations.