The pressing of ceramic powders and granulates is the oldest and most widespread shaping technology for advanced ceramics. The methods of uniaxial and isostatic dry pressing are applied at a high level at IKTS, are constantly developed further and are available to a wide user group for development tasks and also as service.

Products and services offered

- Development of ready-to-press granulates

- Characterization of processability and moldability

- Characterization of the compaction and compression behavior

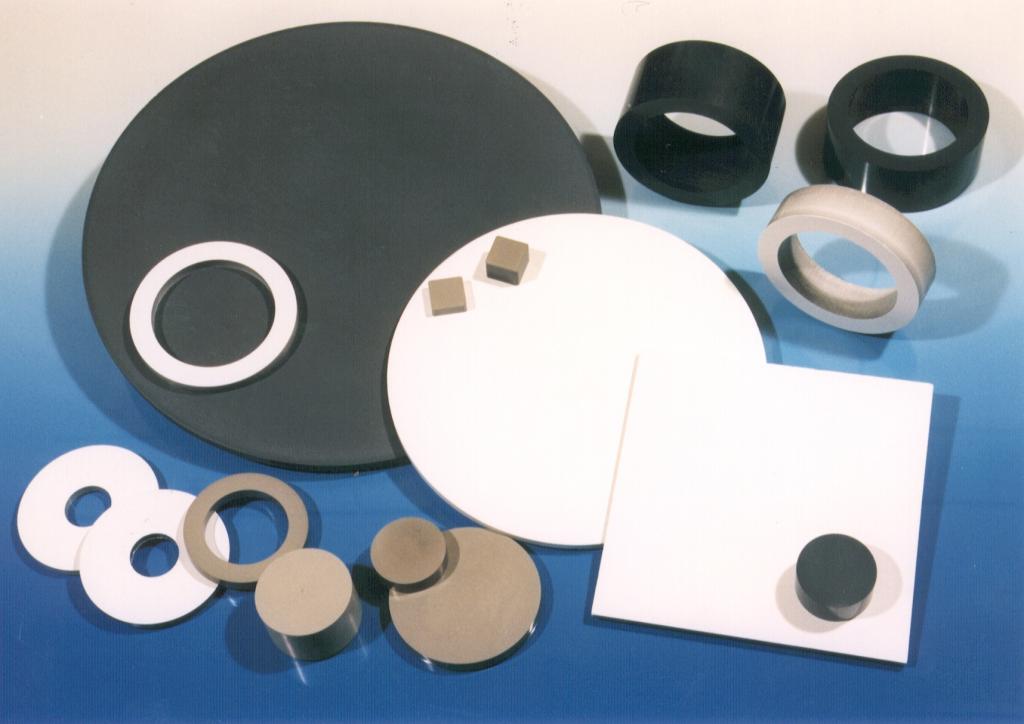

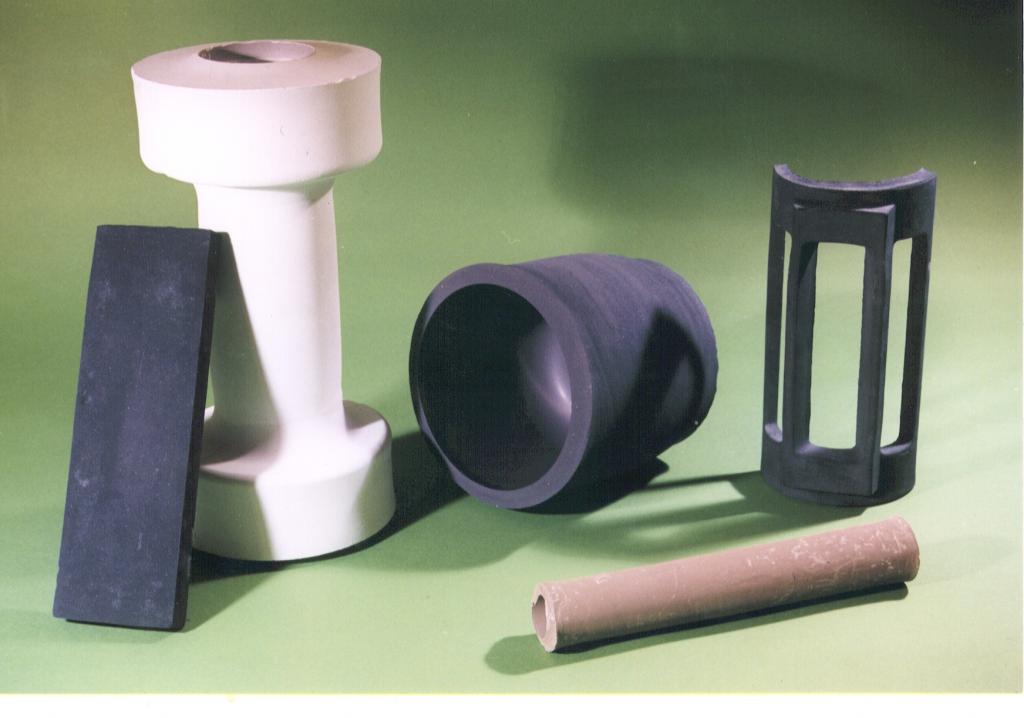

- Component development in connection with the production of prototypes and small series

- Product-related process and technology development/technology transfer

- Special pressing methods (pressing and rolling of layer composites)

- Development of isostatic pressing dies for complex green bodies

- Encapsulation and isostatic pressing of porous green bodies

- Selection and testing of tool coatings

- Pressing of customized powders/granulates with existing plants and tools

Technical equipment

Uniaxial dry pressing

Hydraulic powder press CA NC II (OSTERWALDER AG, max. pressing force 250 kN)

Hydraulic powder press PYXT 200 (EMG GmbH, max. pressing force 2000 kN)

Isostatic dry pressing

Isostatic laboratory press (Weber, max. pressing force 10,000 bar)

Isostatic pilot plant press (EPSI, max. pressing force 4000 bar)