Miniaturization and the integration of as many different functions as possible within components and systems are documented as current developments in automotive engineering, mechanical engineering and construction of plants, in chemical process engineering or medical engineering. Against the background of the required precision, quality assurance, reliability, durability and cost optimization these trends make not only high demands on the manufacturing technology, they also provide new possibilities for the application of high-performance materials. Precise and reproducible individual processes are the requirement which can be integrated in a lean, efficient and perfectly designed process chain.

Protection of resources and cost reduction by miniaturization, near-net-shape production and reduction of the high-performance (and high-price) element to the particular function are at the same time challenge and chance. Ceramic manufacturing concepts allow the combination of different shaping processes e.g. for the formation of thin functional layers and composites as well as material transfer as gradients. A spatially resolved realization of different material properties in complex structured and miniaturized components makes it possible to plan and implement new products, such as intelligent cutting tools, full ceramic heating elements or smart wear parts which are able to detect defects.

Products and services offered

- New manufacturing concepts

- Integration of different functions

- Product development

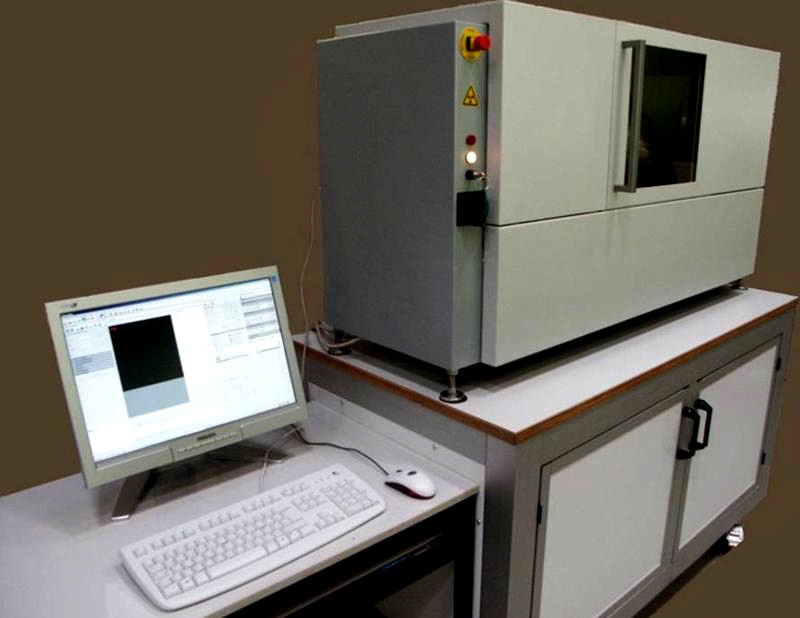

- Non-destructive testing

Examples and references

- Two-component injection molding

- Inmold labeling of powder materials

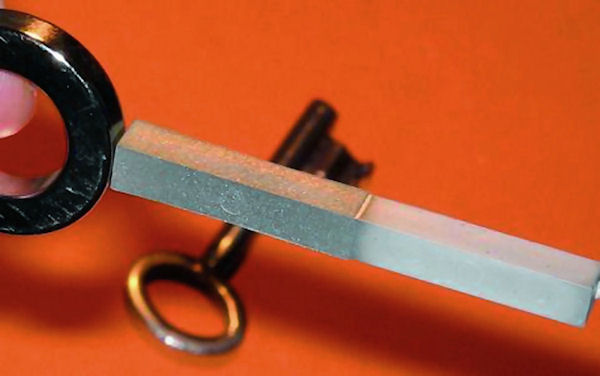

- Steel-ceramic composites