Bulk behavior – Process analysis and complex characterization

Current Research

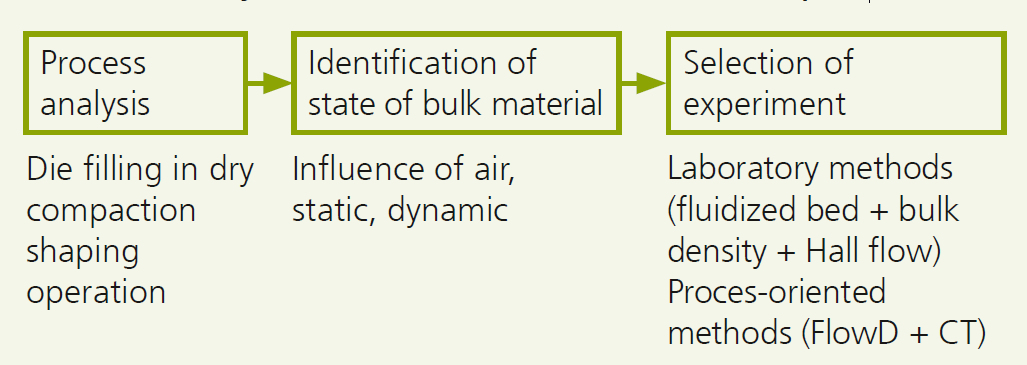

Finely dispersed powders and granules are stored, transported and processed as raw material, as intermediate or final product in almost all branches of industry. Bulk and flow behavior of these materials substantially affect the efficiency of the manufacturing process, as well as the resulting product quality. Comprehensive process analysis and adjusted methods for characterizing flow properties, ideally under process conditions, are the foundation for the development and optimization of tailor-made finely dispersed materials and their associated processing methods. Research and development projects at Fraunhofer IKTS identify the state of bulk materials through process analyzes and create specific characterization concepts. A variety of standardized laboratory methods and self-developed process-oriented methods are available for this analysis. These methods allow for bulk characterization under real process conditions and enable the analysis of basic mechanisms of bulk behavior. In particular, ceramic granules for dry compaction shaping operations can be evaluated comprehensively and in a process-oriented way. In addition, the developed methods are available for the analysis of powders for additive manufacturing, e.g. for 3D powder printing or the evaluation of functional powders. If necessary, methods will be qualified and adapted to meet specific needs of the client. The following specific, process-oriented methods were developed for the analysis of the state of bulk material along the transport route of an uniaxial press:

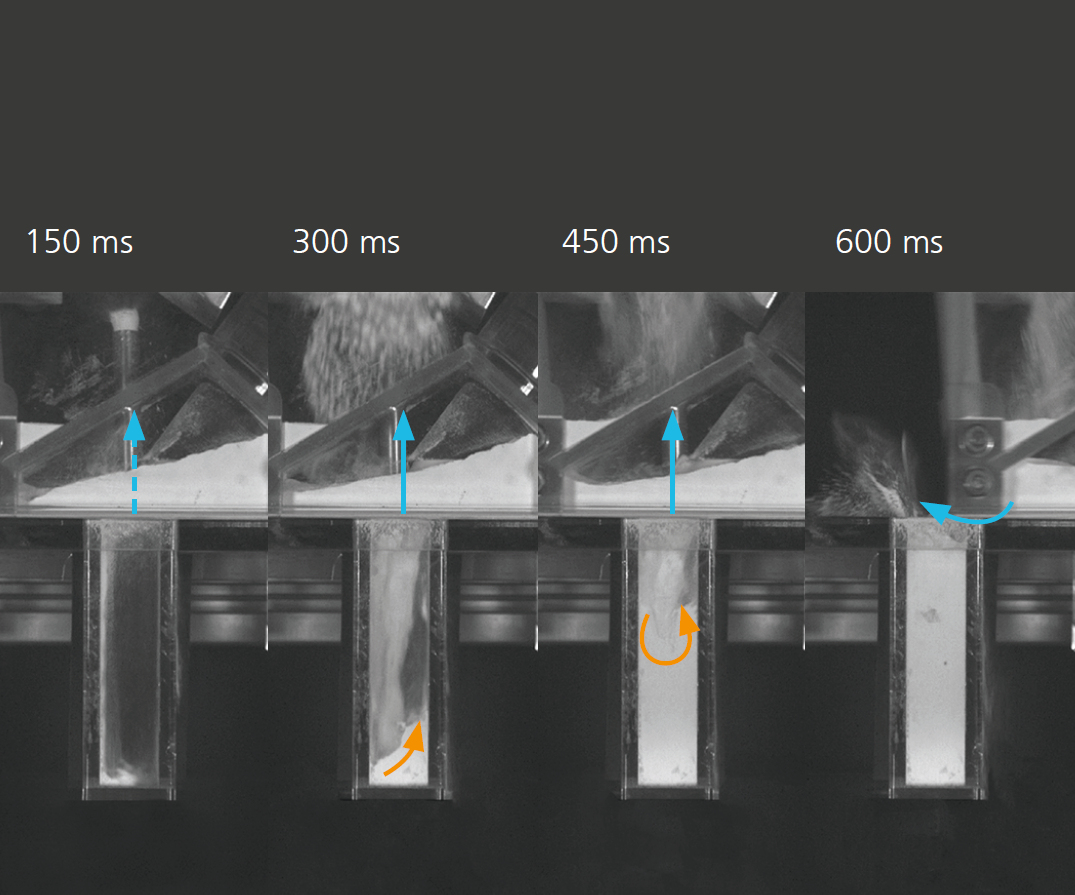

- Visualization of macroscopic flow behavior during the filling process (Figure 1), as well as in the filling shoe, using high-speed video recordings with subsequent qualitative and quantitative assessment.

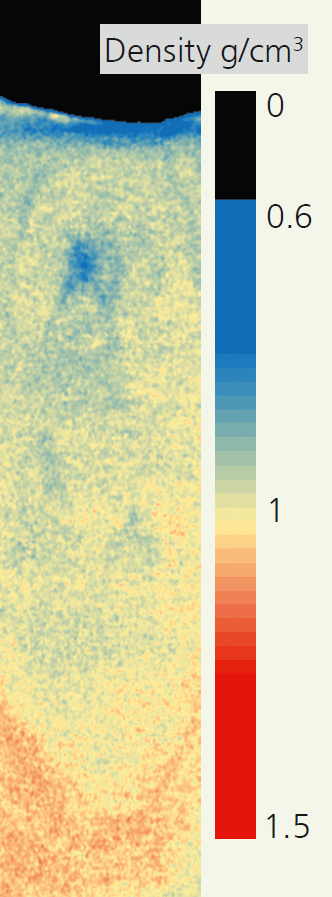

- Qualitative and quantitative analysis of the density distribution of the bulk material in the die (Figure 2) and in the filling shoe by means of non-invasive computer tomography delivers information on the bulk structure.

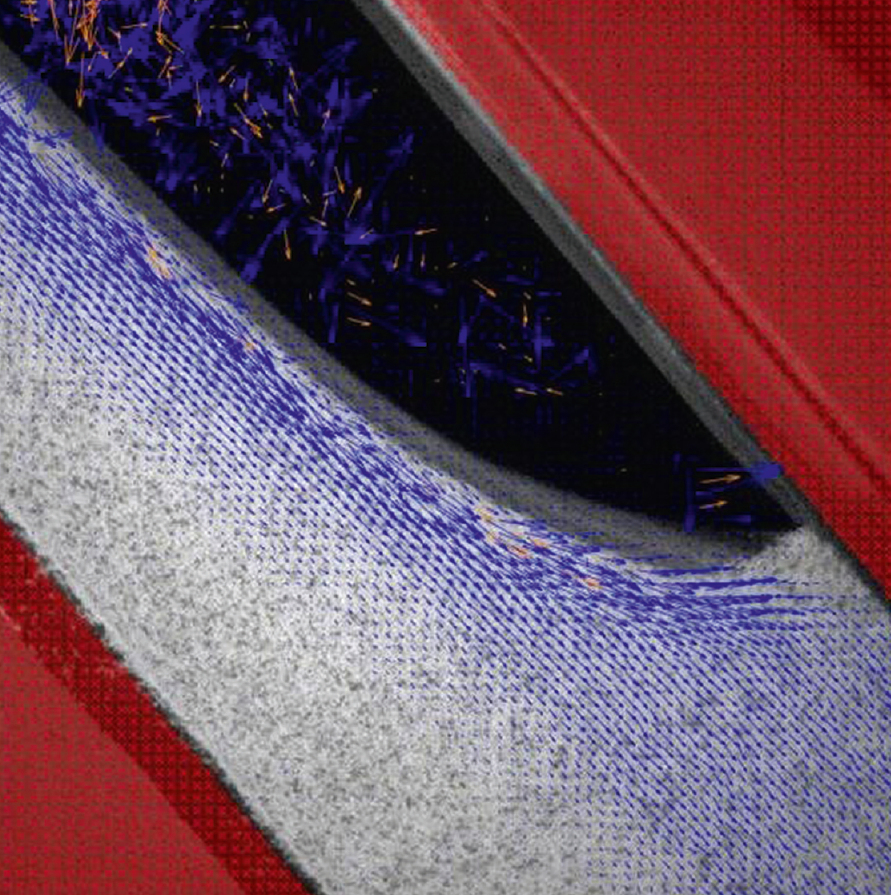

- Within a planar transport route, a high-speed camera captures the microscopic flow behavior. Direction of motion and velocity of the particles can be quantified using “particle image velocimetry” analysis (PIV, Figure 3), down to 40 μm particle size and at a maximum flow rate of 0.3 m/s.

- Assessment of local and temporal segregation of bulk material by space-resolved sampling and particle-size measurement.