3D structural analysis on the micro- and nanometer-scale

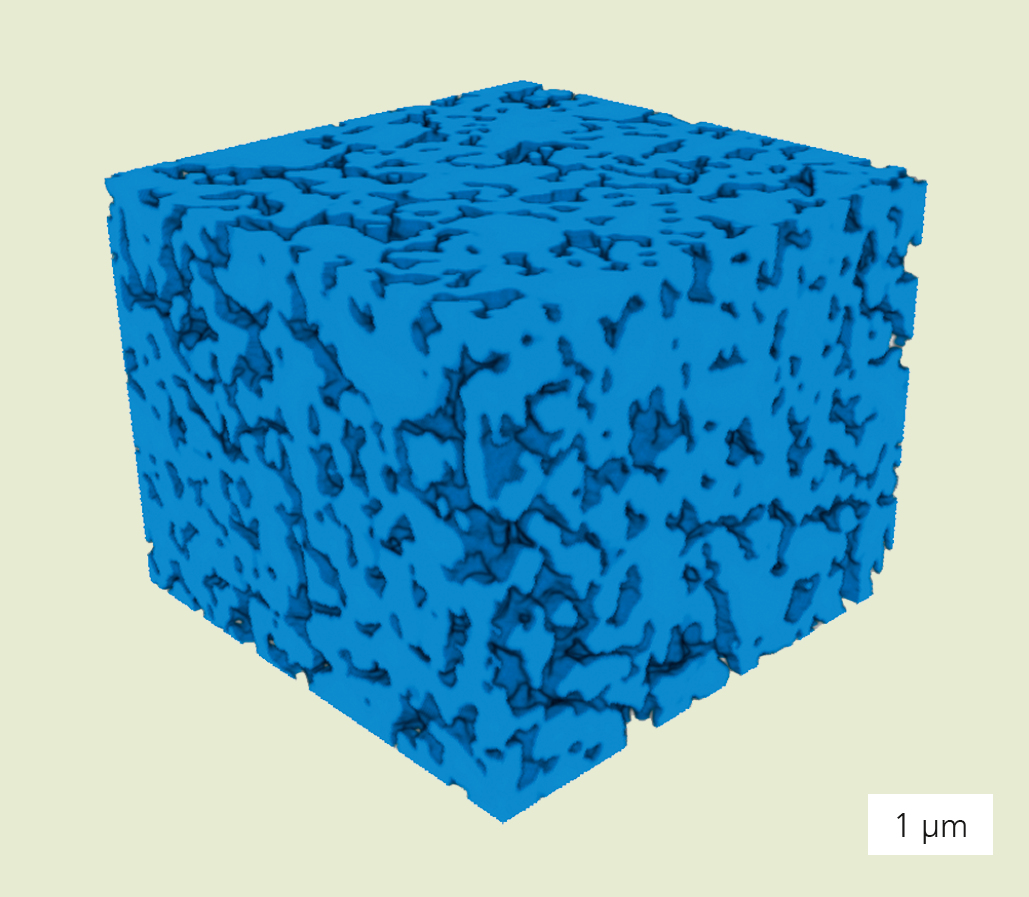

Porous or multi-phase materials can be analyzed using experimental data. This data allows not only for the determination of geometric parameters, but also for the direct creation of models for modeling. Two processes are used for this purpose: X-ray tomography methods (micro-CT and X-ray nanotomography) are suitable for larger volumes with moderate resolution, and for samples of several hundred micrometers in size with a high resolution of up to 50 nm. Serial section methods (FIB tomography) are used for the highest resolutions – up to several nano-meters per voxel. In this second method, the scanning electron microscope with focused ion beam selectively removes material slice by slice (slice-and-view). The numerous imaging and analysis tools (EDS, EBSD) of the scanning electron microscope make high-contrast 3D microstructural data sets possible. Algorithms developed at Fraunhofer ITWM were used to assemble primary data of Fraunhofer IKTS into a 3D image. The quantifiable sample volumes are reconstructed from the several hundred two-dimensional sectional images (Figure 1).

Modeling of material behavior

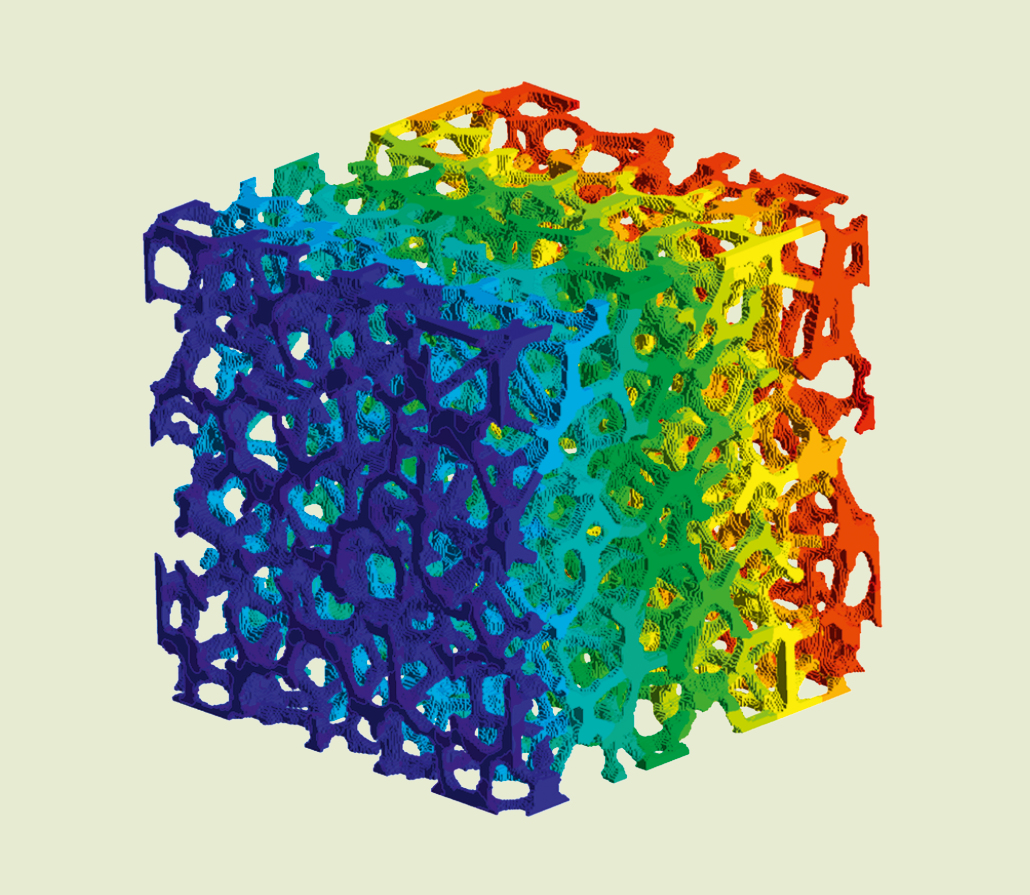

Microstructure simulation on virtual test specimens represents an interesting option for determining structure-dependent material properties and for investigating the correlations between structural parameters and properties. Such simulation makes it possible to circumvent metrological limitations when determining properties, for example in the micro range. Furthermore, it is possible, through virtual analysis campaigns, to reduce the experimental effort involved in sample preparation and characterization. Mechanical properties as well as thermal and electrical conductivities of composite materials and cellular structures, flow and diffusion properties of porous structures can be represented. At first, geometric models are created from the 3D microstructure data sets or with the help of synthetic structure generators (e.g. GeoDict). The physical modeling for basic properties is then done directly in the software tools (GeoDict). For more complex analyses, it is possible to export the microstructure as CAD geometry models into powerful CFD and FEM tools (Fluent, COMSOL, ANSYS). All these options are available to clients at IKTS. The competences for this were developed through exemplary sample applications.

Services offered

- Analysis of ceramic 3D structures in the macro-, micro- and nano range

- Modeling of material behavior on the basis of 3D microstructrure models