Large-area target preparation through correlative work with laser/FIB in FESEM

Current research

High-performance ceramics for structural and functional applications have specially developed microstructures to achieve dedicated properties. To realize this, flawless structures are essential. Errors that occur must therefore be localized, uncovered and characterized quickly.

The new correlative preparation and analysis technique of field emission scanning electron microscopy (FESEM), laser cutting and focused ion beam cutting (FIB) at Fraunhofer IKTS enables fast and accurate preparation, as well as artefact-free microstructure documentation and characterization of the material. Elemental analysis using energy-dispersive X-ray analysis (EDX) also provides exact information about the chemical composition of the microstructure. Other analysis methods, such as computed tomographic (CT) measurements, can be integrated into the analysis process.

The sample is placed once on a holder for preparation and the subsequent analysis steps. All analysis steps are carried out in the FESEM in a correlative, contamination-free manner, without repeated contact with atmospheric oxygen.

The sample point to be examined is localized in the FESEM, documented and saved with its coordinates. The laser module creates crosssections in the microstructure at the stored coordinates. Cutting lengths of up to one millimeter are possible. Using the integrated FIB technology, selected structural areas are finely polished and therefore accessible for high-resolution microanalysis.

The potential of the method is demonstrated by characterizing electrical breakdowns in Si3N4 substrates.

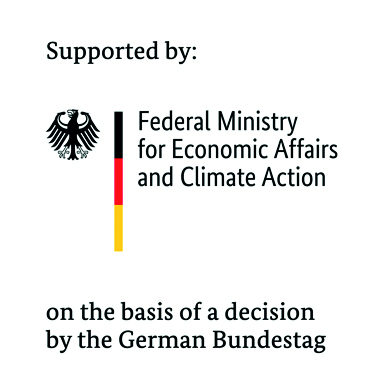

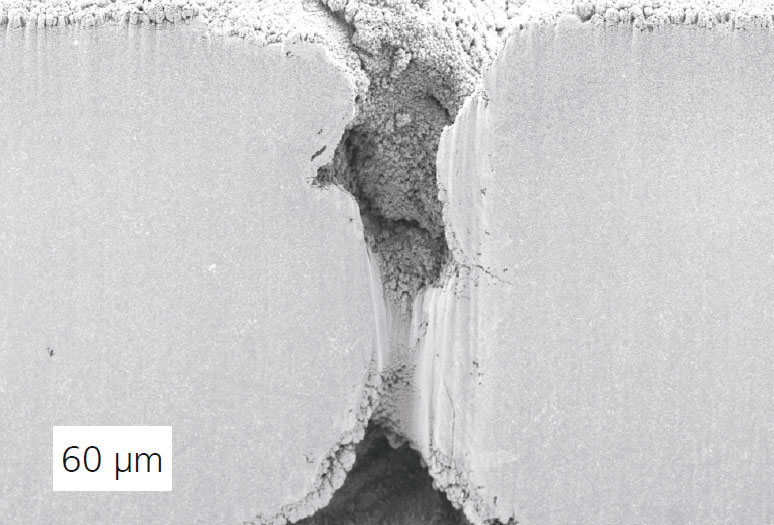

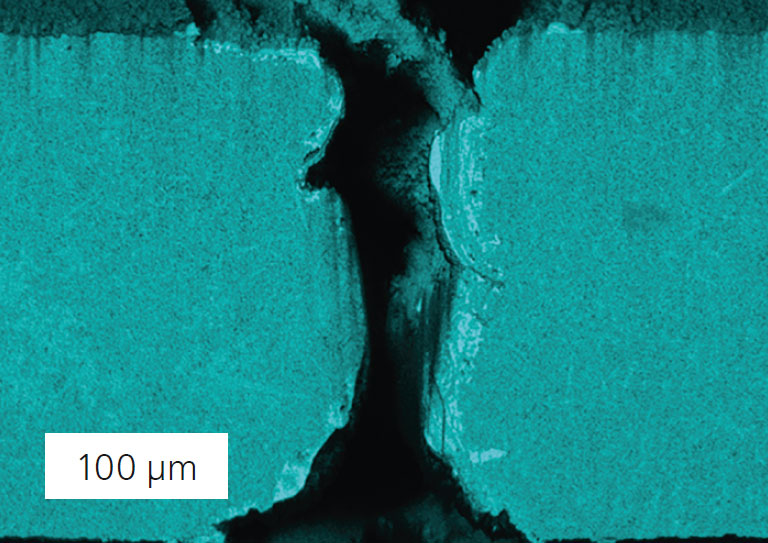

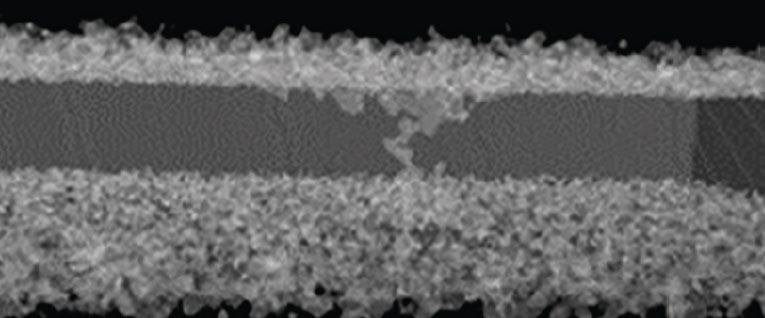

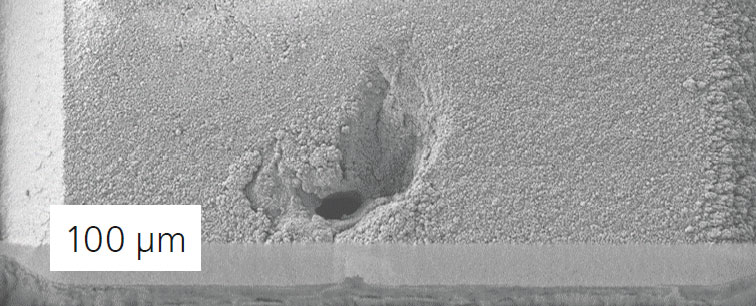

As part of the BMWK project CuSiN (see Zschippang et al., p. 27), a Si3N4 material with thermal conductivity > 85 W/(mK) was developed at Fraunhofer IKTS for applications in power electronics. Dielectric strengths > 40 kV/mm were determined on the substrates. The breakdown channels from such measurements were examined more closely using CT and correlative FESEM/laser-FIB technology to gain a better understanding of the processes taking place. The cut was made through the breakdown channel (Figures 1–4). A crosssectional area of approx. 1000 μm x 300 μm was prepared with laser coarse and fine cuts and then characterized by scanning electron microscopy. The analysis shows that decomposition of the material occurs only in a relatively narrow zone (< 50 μm) around the channel (Figure 5).

Great potential for error analysis

The correlative target preparation using laser and FIB is characterized by excellent target accuracy and the effective and damage-free preparation of crosssections. In many cases, the established mechanical target preparation can be replaced.

We thank the German Federal Ministry of Economics and Climate Protection (BMWK) for funding the CuSiN project (grant no.: 03ETE025A).

Sponsored by