The tribological behavior of components often determines a system’s lifetime. The most important influencing factors are the friction coefficient as well as several wear coefficients, which are characteristic for the respective material pairings under a specific load. Understanding the contact surface mechanisms can help to develop the systems further, thereby increasing the durability of machines and components and making industrial processes more effective and economical.

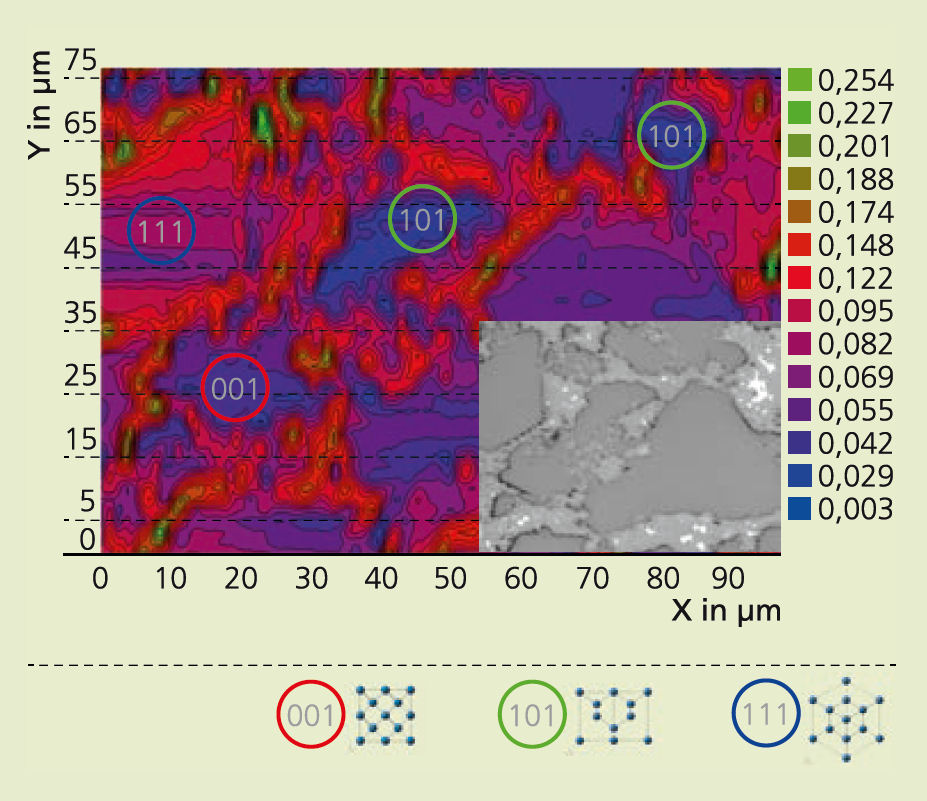

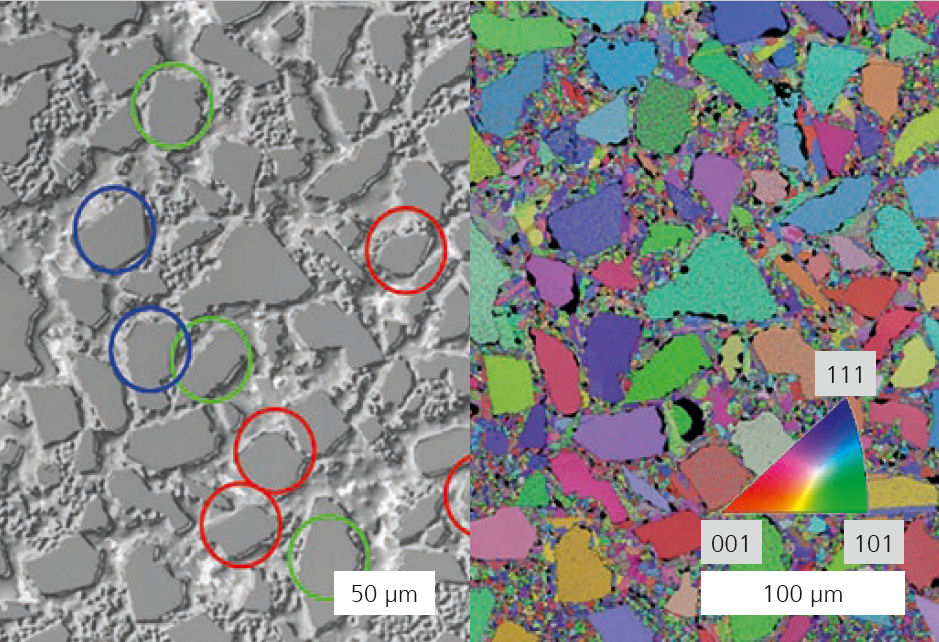

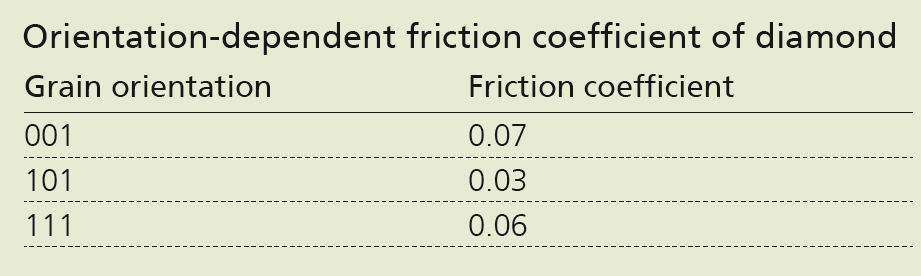

In particular, inorganic and ceramic materials are often used – thanks to their excellent mechanical properties – in applications (e.g. seals, bearings and valves) where high wear resistance is required. In addition, diamond-based materials, such as PCD, ceramic-bonded diamond materials and CVD diamond layers, are increasingly used, as diamond is the material with the lowest known friction coefficient. Since the physical properties are highly dependent on the crystal structure of the components and – in the case of anisotropic properties – on their crystal orientation, experiments were performed on diamond (bonded in a diamond- SiC composite) with a nanomechanical tester (ZHN, ASMEC Advanced Surface Mechanics GmbH) and then correlated with the results of electron backscatter diffraction (EBSD) in the scanning electron microscope. Thus, it was possible to measure the coefficient of friction as a function of the crystallographic orientation on several grains of a sample’s surface. The nanomechanical test also allows two-dimensional (several 100 μm²) measurements of the frictional properties and the modulus of elasticity. The displacement resolution in the normal and lateral direction is around 1 nm and the resolution of the force is 3 to 10 μN at maximum forces of around 2 N, which allows contact pressures (between Brinell indenter and measuring surface) of up to 50 GPa. As a result of these investigations, the orientation dependence of the diamond friction coefficients could be demonstrated (Table 1). They provide a basis for further fundamental investigations of orientation-dependent or anisotropic properties. In addition to the grain orientation, the sliding direction, which can be determined via the EBSD measurement, also has a considerable effect.

Services offered

- Measurement of the grain orientation via EBSD

- Evaluation and correlation of local properties and crystal orientation

The nanomechanical tests were carried out by Dr. Chudoba (ASMEC Advanced Surface Mechanics GmbH) as part of the “EkoDiSc“ project (03X3583H) funded by the German Federa Ministry of Education and Research (BMBF).