AI-based quantitative microstructural analysis of ceramic materials

Current research

The quality and properties of ceramic materials strongly depend on their microstructure. In quantitative microstructural analysis, the grain boundaries must be identified correctly to form the basis for further steps. These boundary data are indispensable for reproducible results in both planimetric and line cutting methods. Traditional image processing methods used for this purpose, such as segmentation based on simple threshold values or other separation methods, reach their limits depending on the optical appearance of the microstructure. Therefore, grain boundaries are often detected manually in practice, leading to high costs, time expenditure and subjective results.

In recent years, modern AI-based image processing methods have proven their worth in diverse use cases with complex visual problems. They are becoming more and more popular in the field of material science.

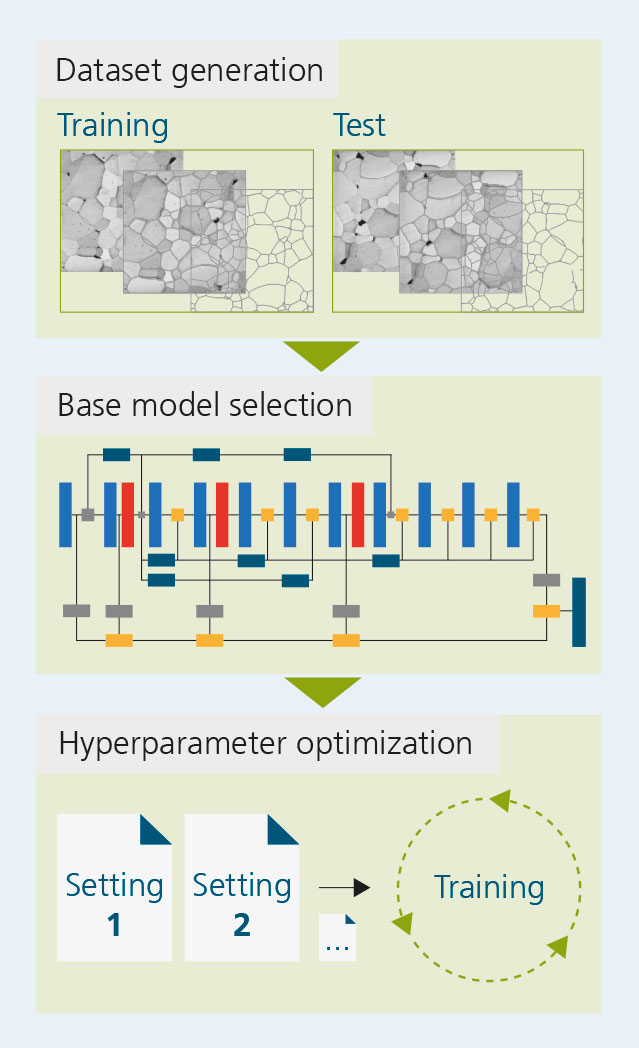

Fraunhofer IKTS has developed a deep learning approach based on convolutional neural networks (CNN) for the detection of grain boundaries. This approach is based on a data set consisting of microstructural images of the material to be analyzed and the corresponding manually marked grain boundaries (ground truth). A special architecture from the field of edge segmentation was chosen for the CNN. The CNN was trained with specific, specially developed loss functions. Extensive automated hyperparameter tuning helped to find optimal hyperparameters, i.e. parameters that influence the training process and thus the final performance of the CNN.

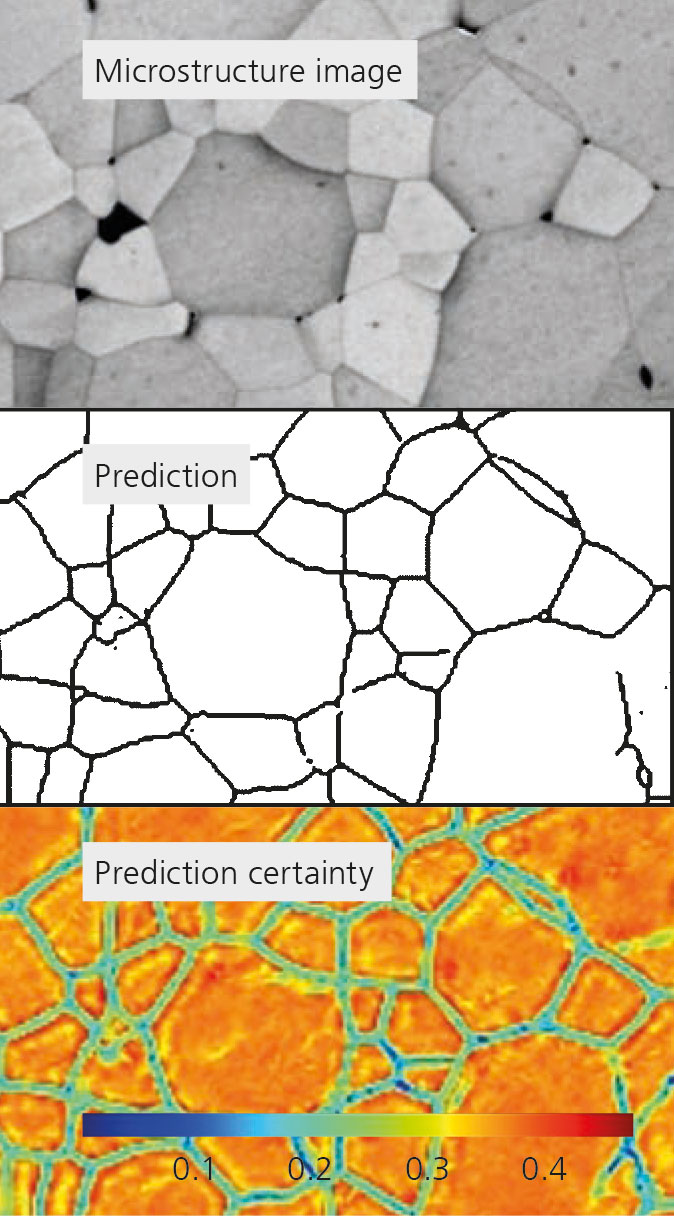

The model performance is evaluated both visually and statistically. For the visual evaluation, model predictions are compared with the ground truths. In addition, visualizations of the predictive security provide information on which areas of the structure are challenging for the model.

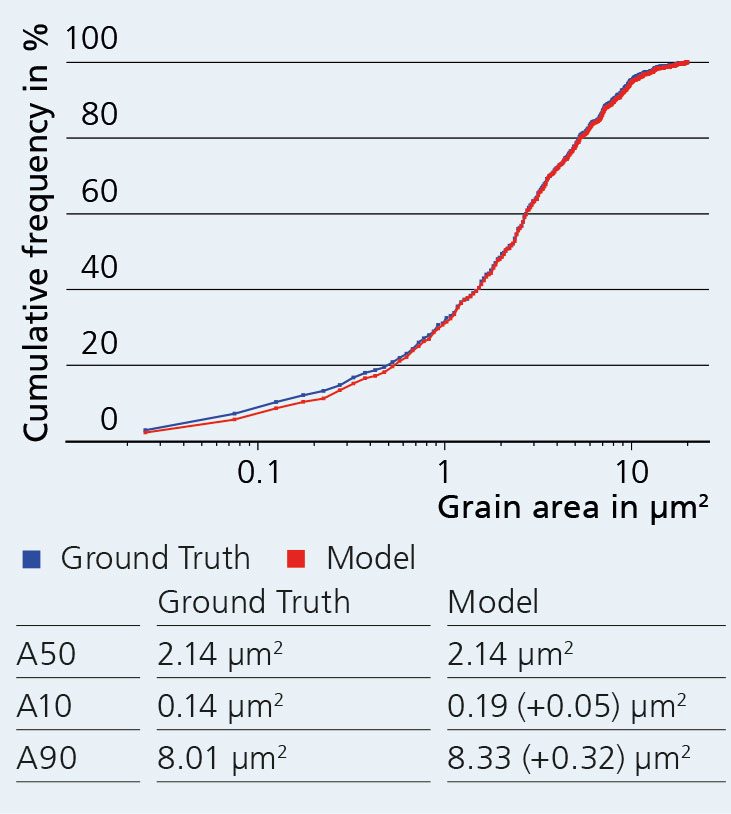

During the statistical evaluation, both ground truth and model predictions are analyzed and compared planimetrically. The following diagram shows results using aluminum oxide (Al2O3) as an example. The training of the

underlying model is based on microstructural images with only about 1300 grains.

Services offered

- Reproducible microstructural analysis incl. adapted ceramographic microstructural preparation and FE-SEM images

- Development of AI models for the microstructural analysis of different material systems

- Training and analysis of customer data and materials for evaluation of the models