Superhard materials of hardness > 45 GPa are typically composed of wear-resistant materials based on diamond and cubic boron nitride (cBN). Commercially available superhard materials include PCD (polycrystalline diamond) and PCBN (polycrystalline cubic boron nitride). In addition, wear-resistant ceramic-bonded cBN and diamond materials have been developed at Fraunhofer IKTS. These materials are prepared in ambient pressure conditions,

allowing for geometries that are unattainable in highpressure processes. The possibilities for SiC-bonded diamond

materials are especially diverse and include such geometries as pipes, seals, and bearings.

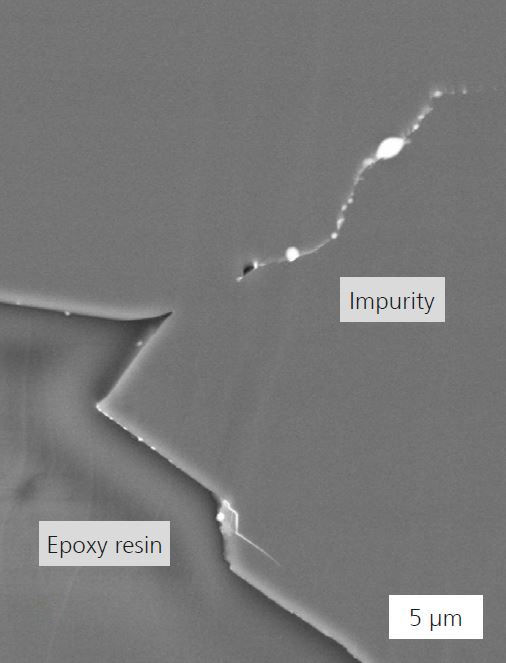

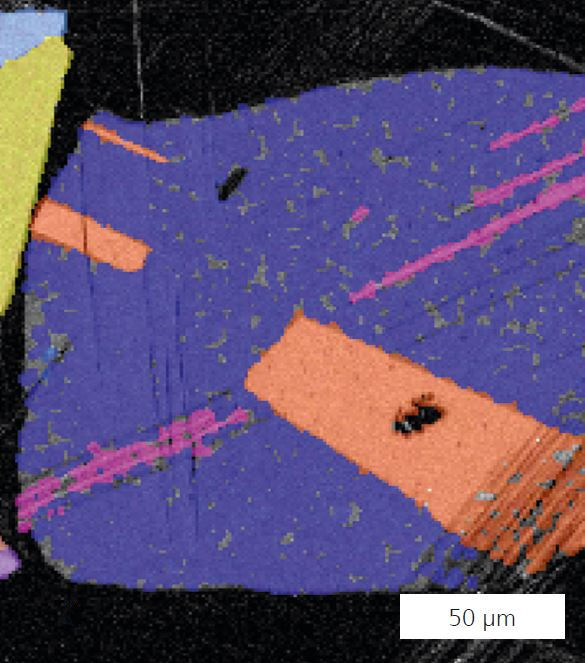

The strong effect of interfaces and damage to the metastable hard materials in the material preparation stage on the properties of superhard materials spurred the development and testing of suitable preparation and characterization methods at Fraunhofer IKTS. Besides methods for determining mechanical properties, damage-free methods for preparing superhard powders, materials, and hard component-matrix interfaces were developed for subsequent analysis of microstructureproperty correlations. Scanning electron microscopy can be

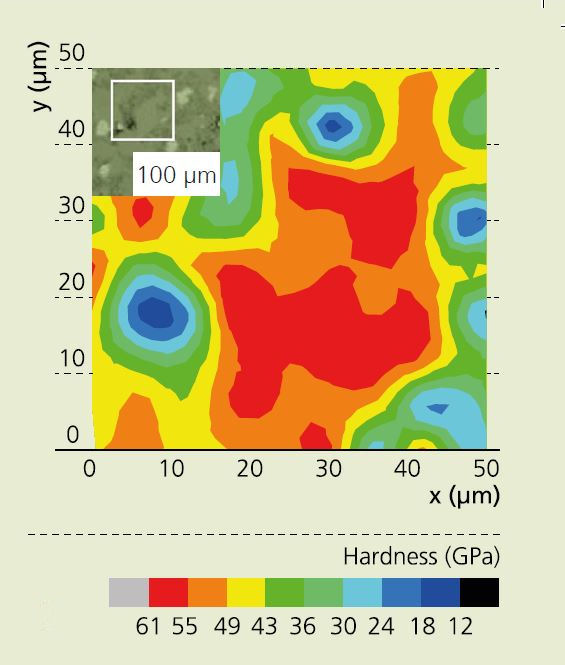

employed, e.g., for detection of defects in diamond or CBN grains (Figure 1). The use of an EBSD (electron backscatter diffraction) detector enables determination of twinning or the precise grain size distribution of diamond grains in PCD. Epitaxial growth of SiC on diamond in reactively produced diamond-SiC composites can also be detected using these methods. Transformation of cubic boron nitride to the stable hexagonal boron nitride modification or of diamond to graphite can be verified by micro-Raman spectroscopy with local internal stress analysis. Improvement of nanoindentation techniques to allow integration of an in-situ indenter into the SEM has created the possibility of detecting distributions of elastic properties and hard-ness in materials with submicron resolution. This in turn enables investigation of grain boundary phases in multiphase materials. Figure 3 shows a hardness map for a boron suboxide (B6O) material. The high hardness of the B6O grains and the pronounced drop in hardness at the grain boundaries and in the oxide binder phase regions are evident. This drop in hardness is also the reason for the extreme differences in hardness between B6O single crystals and sintered materials (< 33–38 GPa).

Services offered

- Microstructural and failure analysis of materials and components

- Characterization of diamond and cBN powders and materials

- High-resolution mapping of elastic properties and hardness