Open-celled ceramic foams can be used, among other applications, as receiver parts of concentrated solar power plants (CSP). Their main task is to collect the solar irradiation that is focused onto the receiver by a field of mirrors, and to transfer the irradiated heat energy to the air flowing across the receiver, all with as little loss as possible. For this purpose, Fraunhofer IKTS is developing silicon carbide (SiC) foams which are able to withstand the desired operation temperatures of above 1000 °C for long periods of time. Current research investigates the influence of the structural properties of foams, such as cell size and strut dimension, on the thermal receiver performance. Based upon these properties, numerical models have been developed and verified which allow to predict each absorber’s thermal performance. Therefore, they can be used to identify the optimal design of the receiver foam elements.

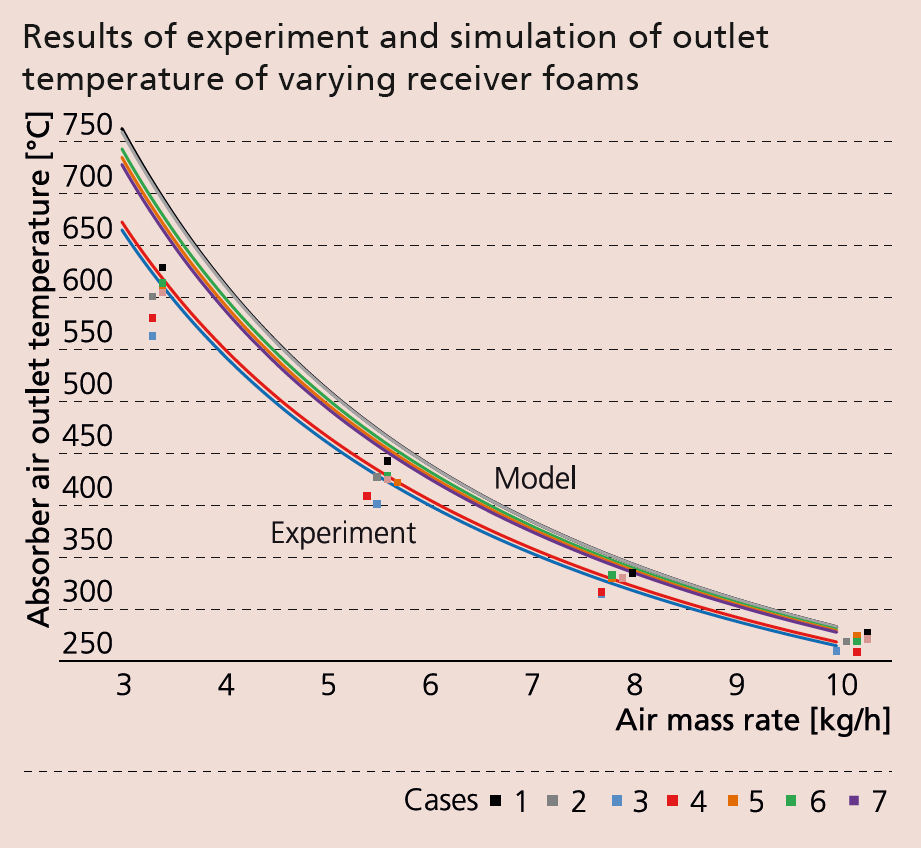

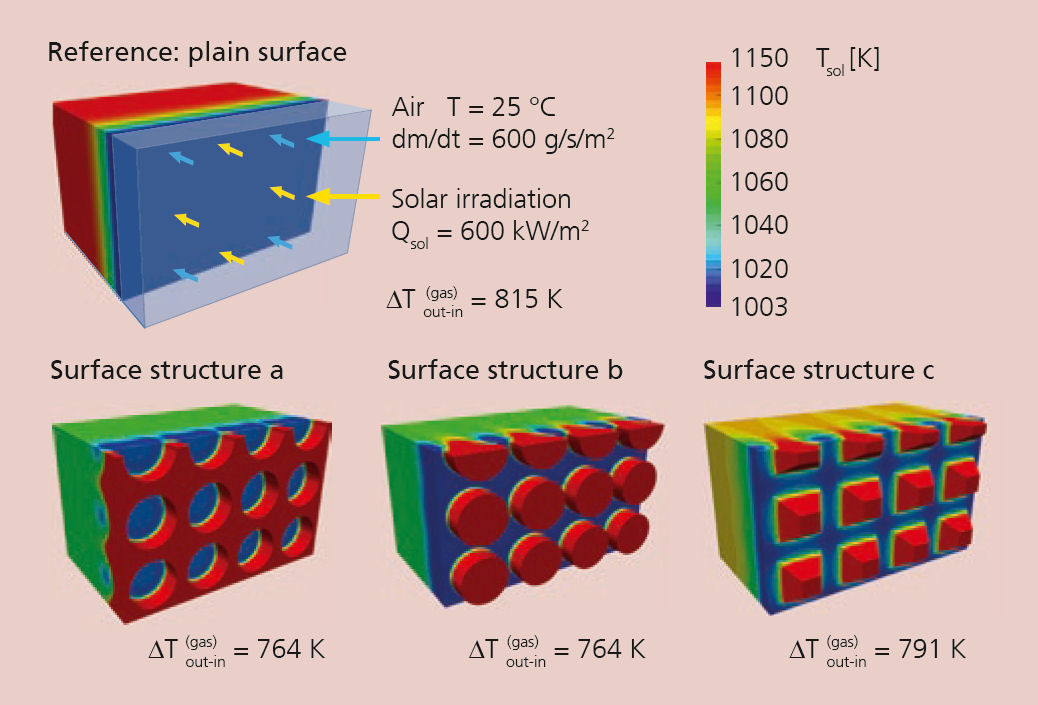

Thermal absorber performance depends on the interaction between absorption and scattering of the solar and thermal radiation emitted by the foam, the heat transfer between solid and fluid domains, and the conductive (solid material) and convective (air) heat transport within the foam structure. All these processes are represented in a sophisticated homogenized continuum multiphysics model approach. In addition to analyzing general trends, the model was also used to examine the potential of multilayered absorbers and surface structuring for improving absorber performance. It was shown that simple, unstructured foams attain the best performance, and their production is more cost-efficient to boot. A cooperation with CENER institute (Spain) under the “CAPTure” EU project provided the opportunity to validate the model results with test data from an experimental absorber test set-up.

Services offered

- Development of open-celled ceramic foams for high-temperature applications

- Manufacturing and analysis of test samples and small series

- Development and adjustment of models for the prediction of the properties of complex structure

We gratefully acknowledge the EU for the funding of the project “CAPTure” (Framework: H2020-LCE-2014-1, No.: 640905).