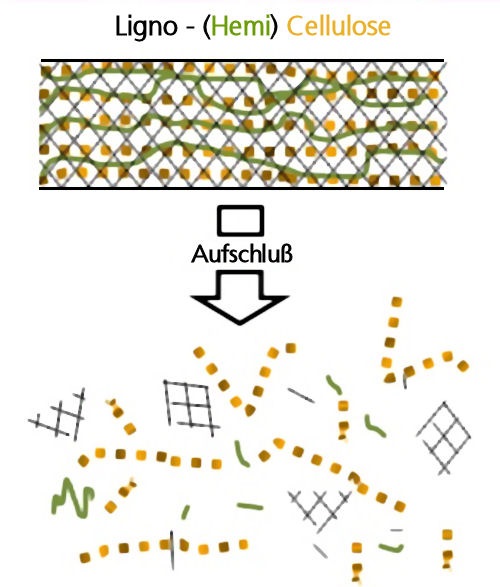

The Transformation of solid organic matter into water-soluble basic building blocks – so called hydrolysis - is a crucial step in microbial conversion and thus essential for efficient utilization of chemical and energy potential of biomass at all. Hydrolysis is rate-limiting for a variety of biological processes often caused by a complex molecular structure of the organic feedstock. Against this background it is obvious that acceleration of this step by physical, chemical or biological means will improve most or even enable subsequent industrial processes for production of renewable energy like biogas or bio-fuels.

Working group does research in terms of development, optimization and evaluation of disintegration processes for various biomasses. Main criteria for efficiency of particular disintegration device or method are effects on subsequent processes like hydrolysis, saccharification, fermentation as well as impact on particle size distribution, enzyme activity and viscosity. This kind of testing can be conducted in lab scale as well as in large pilot scale. According equipment, e.g. a substrate treatment container with several disintegration devices is available at “Application Center Bioenergy” (see Application Center Bioenergy Pöhl).

Services offered

- Development of treatment strategies for substrate-and application-specific disintegration (e.g. in the fields of biogas, bioethanol, biorefinery),

- Evaluation and comparison disintegration methods from lab to pilot scale

- Assessment of primary disintegration effects by means of rheological, chemical, biochemical and particle size analysis

- Evaluation of impact on subsequent processes by means of fermentation tests (see biomass fermentation), process tomography (see mixing processes and reactor optimization) and adjusted fermentation experiments

Equipment

- Mechanical shredding technology (laboratory scale to industrial scale) as Granulator, several homogenizers , disc mills, twin-screw extruder

- Reactors for biological hydrolysis

- Reactors for thermal and / or chemical digestion

- Measurement technique for assessing particle size distribution from nanometer to millimeter (laser diffraction spectrometer)

- Measurement for the evaluation of particle size and shape of fibrous solids in micron to cm – range with imaging methods (fiber shape, QICPIC)