Efficient fertilization: adapted nitrogen contents in fertilizers

Current research

Nitrogen: valuable and problematic

Nitrogen is an essential plant nutrient for agriculture. Manure and fermentation products from biogas plants are important sources of nitrogen. However, high production volumes, as they occur along with intensive livestock farming, cannot be applied to fields throughout the year. Thus, the nitrogen volume from autumn must be stored until the following spring. Low nitrogen concentrations require large slurry storages. With the beginning of plant growth in spring, large nutrient quantities have to be applied in a very short time, which means a lot of stress for the soil and strains the machinery.

Changing the nitrogen concentration

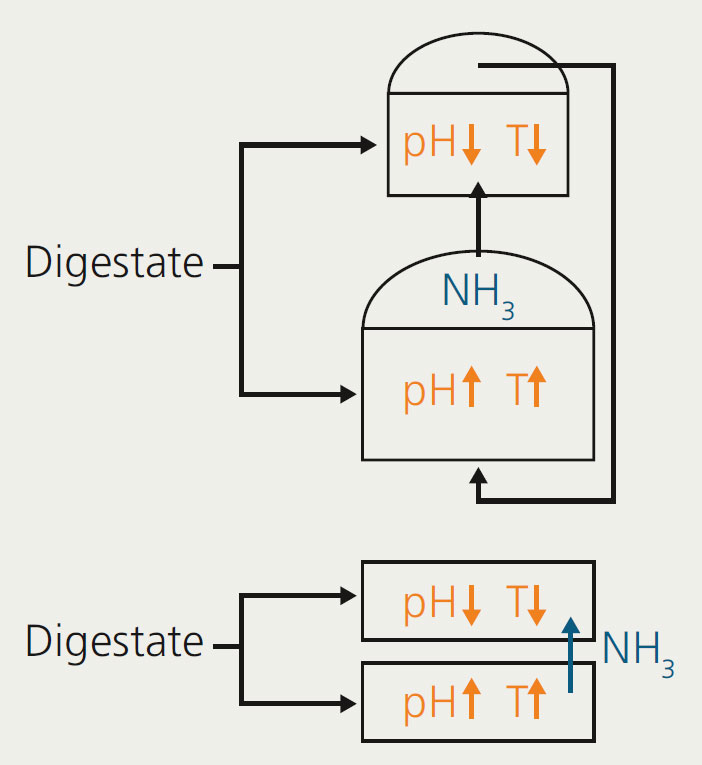

In the “N-Shift” project, two methods were tested to influence the nitrogen content in fermentation products in such a way that optimized autumn and spring fertilization becomes possible. Ammonia was transferred from one part of the fermentation product to another part by means of circular stripping or membrane contactor processes. The solubility of the ammonia and thus the driving force for the mass transfer were specifically influenced by varying temperature and pH value.

Circulation stripping

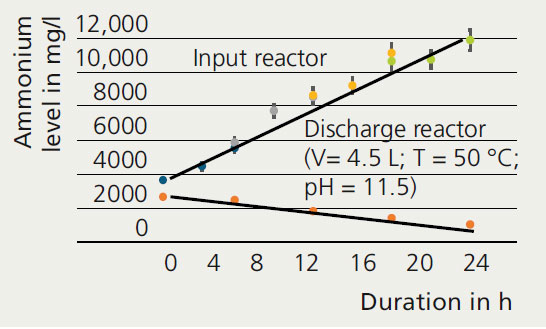

During circulation stripping, an active exchange of stripping gas takes place between two reactors in a closed loop. In the basic discharge reactor, the stripping gas absorbs ammonia from the fermentation product. In the acidic feed reactor, ammonia from the stripping gas is dissolved as ammonium in the fermentation product. Depending on the set milieu conditions and intensity of stripping, up to 3.2 % of the ammonia load could be transferred per hour.

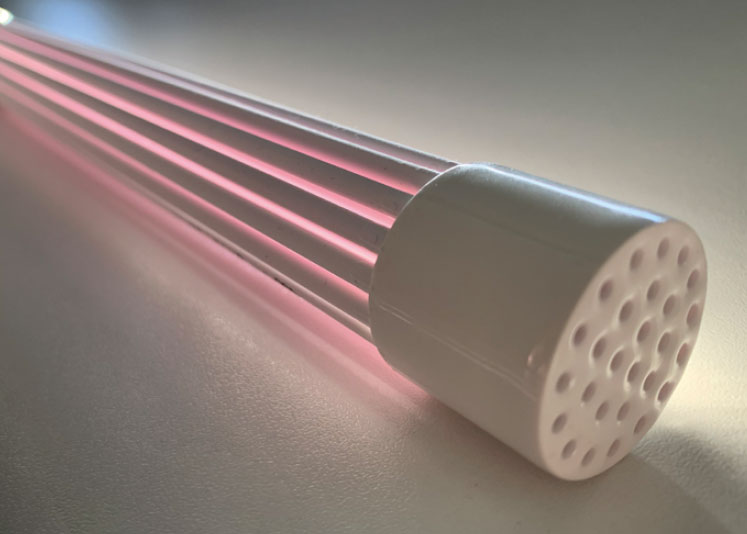

Membrane contactor

In the membrane contactor, both fermentation product phases are separated by a hydrophobic ceramic membrane, which must not be wetted by liquid and only allow the gaseous transport of ammonia. The membranes developed showed stable hydrophobic properties and prevented effectively any mixing of the liquid phases. Ammonia concentrations in the receiving phase were 3 times higher than in the discharging phase.

Advantages for fertilization

The autumn fertilizer produced in the project is characterized by very low nitrogen contents (especially NH3), phosphorus fixation and alkaline properties (lime substitute). The spring fertilizer contains high concentrations of available nitrogen and phosphorus. This means that more mass can be applied in autumn, which saves storage capacity. Overall, nitrogen losses are significantly reduced and the plants are fertilized in a targeted manner.

Sponsored by