Biomass is a limited resource that may not compete with food or feed production. Therefore it is crucial to develop sustainable and also economic concepts and methods for energy but also material use of biomass. In that field a direct transfer of results from the laboratory scale to industrial practice is hardly possible. Therefore a technical intermediate step is necessary and useful in order to work with practically relevant quantities of biomass and to ensure controlled conditions at the same time. The application Center Bioenergy has appropriate infrastructure in terms of that and technical equipment to close the gap between laboratory and practice. This is interesting for a variety of complex research activities as well as for technology developers, plant engineers, manufacturers of measuring equipment, etc. from the private sector who want to test their products in a practical but at the same time carefully controlled scientific and technological environment. For public and industrial research many space with modern equipment are available. Test facilities can be supplied with biomass, fermentation substrate, with raw or upgraded biogas. Similarly the safe disposal of process products according to all rules of compliance is guaranteed. Necessary analyzes can be performed directly in a new laboratory on site.

Technical Equipment

- biogas pilot plant (fully automated, active volume 10m³) (figure 2)

- plug flow reactor (fully automated, workload 1m³)

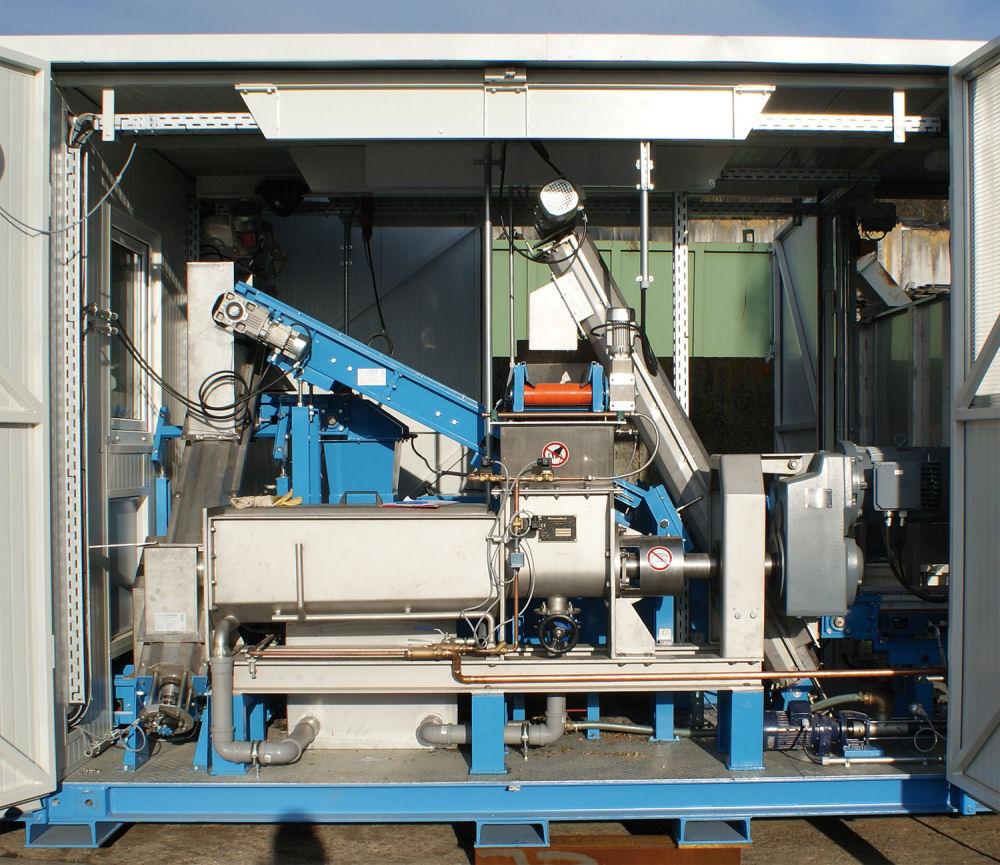

- Integrated biomass treatment system (container)

- Test rigs for biomass treatment

- Mechanical disintegration (extrusion)

- Separation (deconservation of silage)

- Test rigs for digestate

- Drainage

- Compaction

- Test rigs for biogas upgrading

- catalytic desulfurization

- activated carbon adsorption

- membrane preparation

- Ultrasonic degasification reactor (fully automated workload 1m³)

- pilot fermenter for analysis of stirring and mixing processes

Services offered

- Analytical determination of specific biogas yields in continuous processes

- testing of systems for biomass conversion

- Determination of nutrient and trace element limitations in the fermentation process

- Process definition and design of fermentation processes

- Process development for on-demand production of biogas

- Feasibility studies and economical evaluations

- Measuring and monitoring of existing plants in order to improve performance

- Development and implementation of special solutions for biogas cleaning and digestate treatment