In-situ detection of cracks in microchips by nano-XCT

Current research

High-resolution transmission x-ray microscopy for in-situ investigation of 3D structures

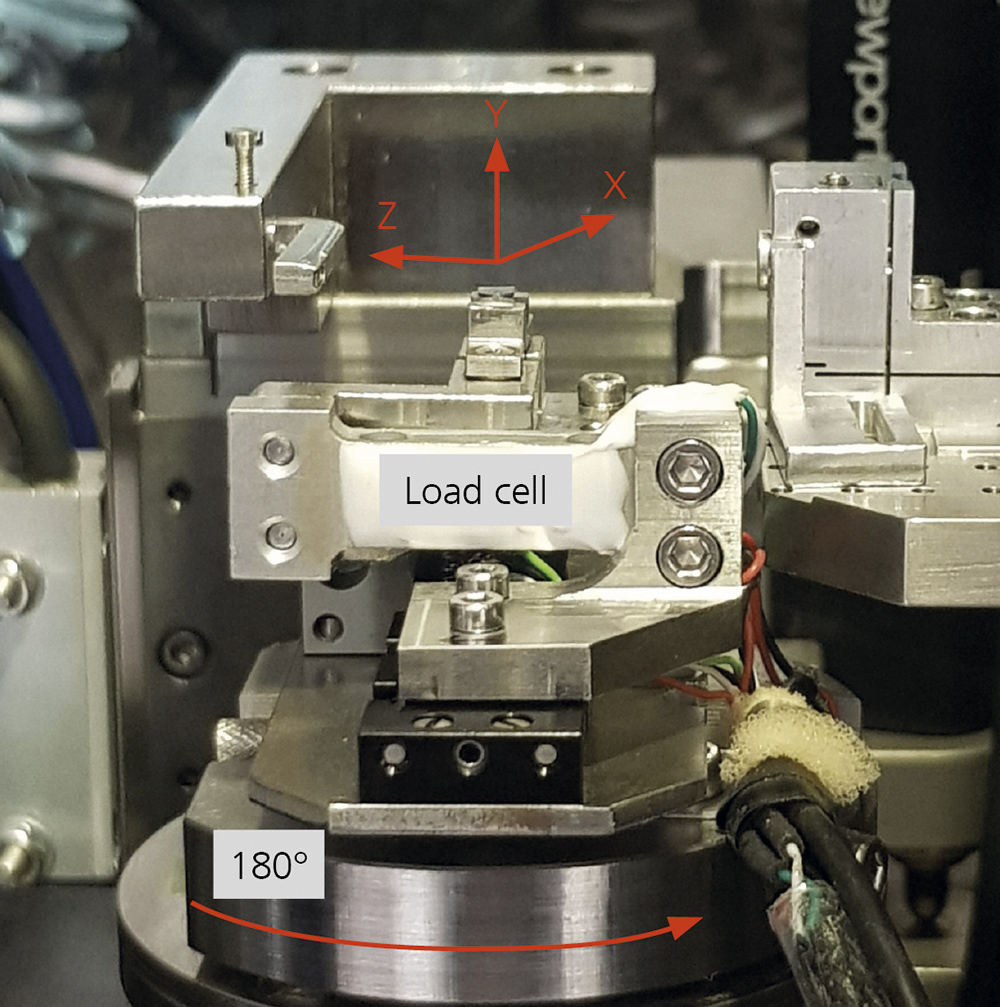

Investigations of crack evolution in microchips currently fail due to the insufficient resolutions achieved by the methods employed. Therefore the Fraunhofer IKTS enhanced a laboratory- based Transmission X-ray Microscope (TXM) which is used for nano-X-Ray Computed Tomography (nano-XCT) with a novel miniaturized Double Cantilever Beam (micro-DCB) test system. This tool allows full tomographic access to the region of interest (ROI) under defined mechanical load, which enables insitu 3D imaging at resolutions of above 100 nm.

For optimal imaging, the micro-DCB sample needs to be about 50–80 μm thick. The crack growth is driven by controlled piezo displacement with steps of 50 to 100 nm during continuous force measurement.

In-situ micro-DCB study of crack propagation in microchips

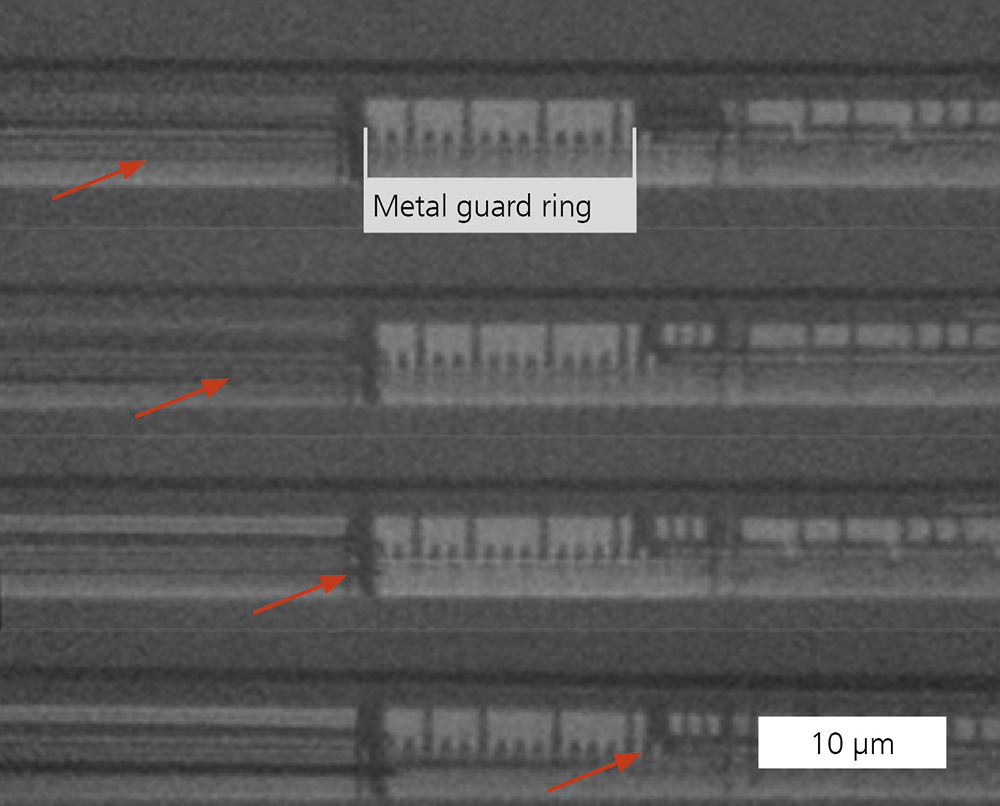

Crack propagation was localized and visualized in an in-situ study of the pathways of cracks in fully integrated multilevel interconnect structures during mechanical loading. Also, the delamination of the crack in weak dielectrics and along dielectric interfaces was determined. To prevent fracture and mechanical damage of the microchip, metal guard ring (GR) structures are integrated into the on-chip interconnect stack, with the aim of stopping the micro-crack propagation or redirecting cracks. The in-situ micro-DCB test allows a non-destructive study of the complex failure modes in real interconnect stacks. This opens the discussion of the impact of process-induced thermomechanical stress and Chip-Package-Interaction (CPI) on reliability. These studies provide the information needed to design guard ring structures for future advanced technology nodes and to guarantee the requested product lifetime.

Services offered

- In-situ visualization of cracks in materials with sub-100 nm resolution

- Determination of weakest components and interfaces in materials based on 3D data

- Quantitative determination of the fracture toughness of materials

The project was funded by SRC in accordance with the member-specific research agreement.