Finite element simulation of chip molding compounds based on nano-XCT data

Current research

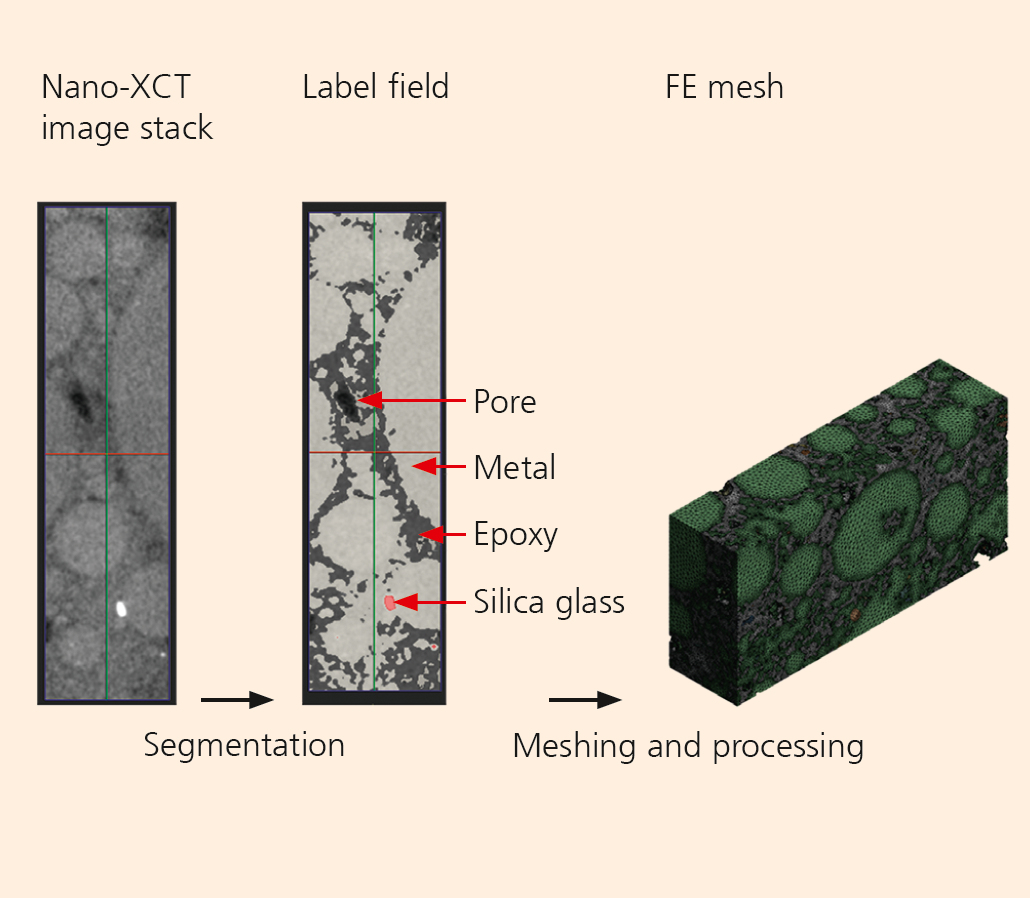

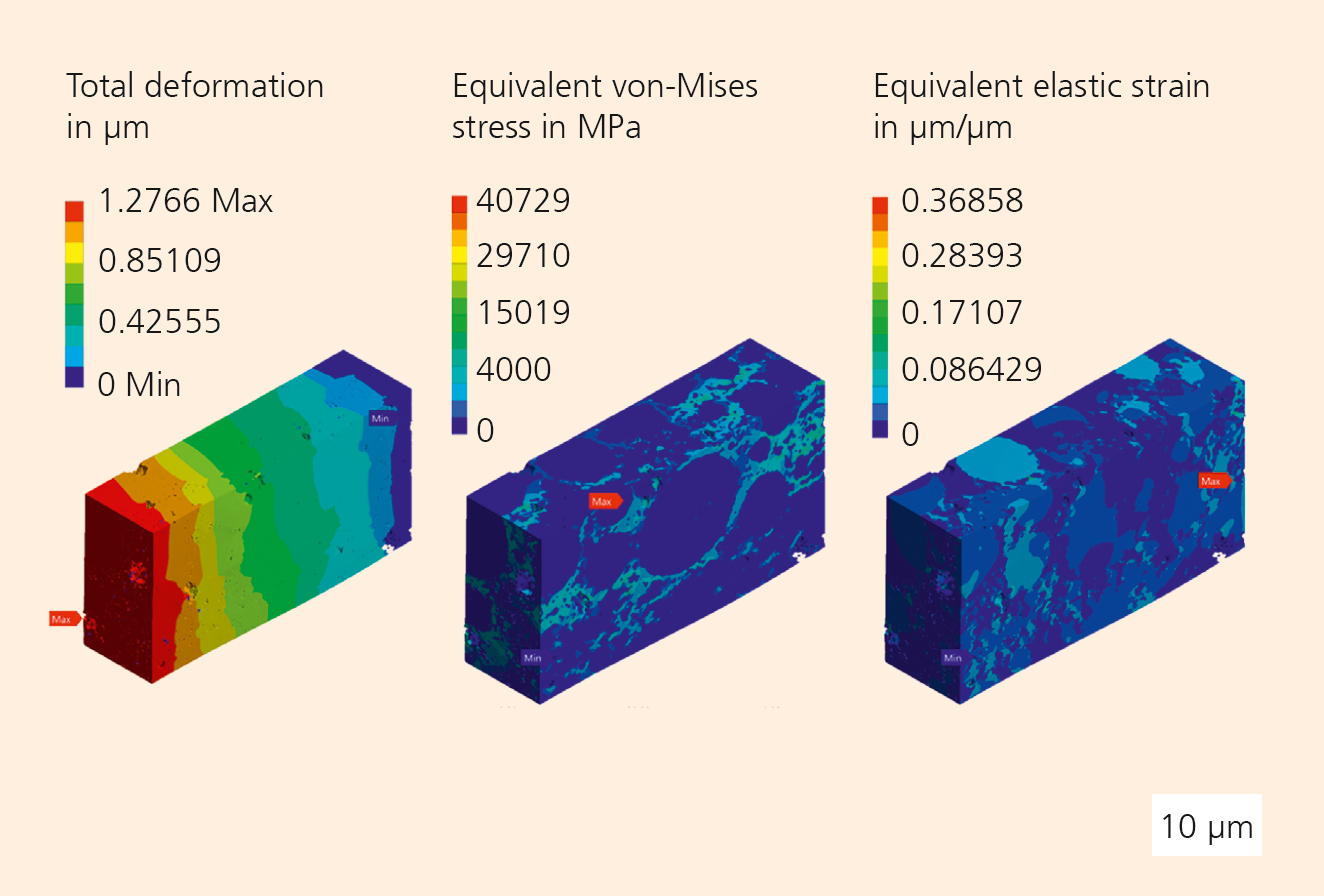

X-ray computed tomography (XCT) is a non-destructive method for the 3D characterization of the internal structures of an object, familiar in particular from diagnostic medicine. Over the last decade, high-resolution nano-XCT has been increasingly used in material science and engineering to image the internal structure of objects and the microstructure of materials in high resolution below 100 nm. Images taken from different perspectives are assembled to reconstruct the acquired 3D data. In the process, problems can occur, such as mechanical axis instabilities, misalignment, motion of samples, missing data, and physical artifacts. In order to reduce or eliminate these and gain artifact-free volume data, scientists of TU Dresden and Fraunhofer IKTS have jointly developed specific correction methods. The resulting software package employs machine learning for data recovery, computer vision for motion compensation, and statistical optimization methods for misalignment correction, in order to improve the reconstruction quality and accuracy of the acquired data. With these precise 3D data, it becomes possible to create computer models which consider the hierarchical microstructure of materials and morphological features, such as pores or reinforcement components. Simplified models, currently used to reduce the complexity of the material system in finite element simulations, can then be replaced by these more complex nano-XCT-based models, which allow to understand the local material response of the real material structure to an applied load. Chip molding compounds are polymers used to encapsulate microelectronic products, such as processors and memory chips. Material simulations have become a critical part of the design process of these materials to ensure performance and reliability. The 3D morphological data of the molding compounds obtained by using nano-XCT are used as input for the simulation model. First, a segmented surface geometry of a three-dimensional object is produced from the image stack (Figure 1). Then, the surface geometry is transformed into a volume geometry using ANSYS reverse-engineering tools. In the example shown above, a tetrahedral mesh with 1.2 million nodes and 4.6 million elements was generated in order to conduct compressive stress simulations. The resulting total deformation, equivalent von-Mises stress and equivalent elastic strain fields of the heterogeneous molding compound model are illustrated in Figure 2. The results show that the size and placement of the glass spheres included in the material considerably influences the mechanical properties of heterogeneous molding compounds. The methodology is suitable for all kinds of material systems and allows to establish models based on real geometries by transforming 3D image data into a finite element model with accurate morphological features.