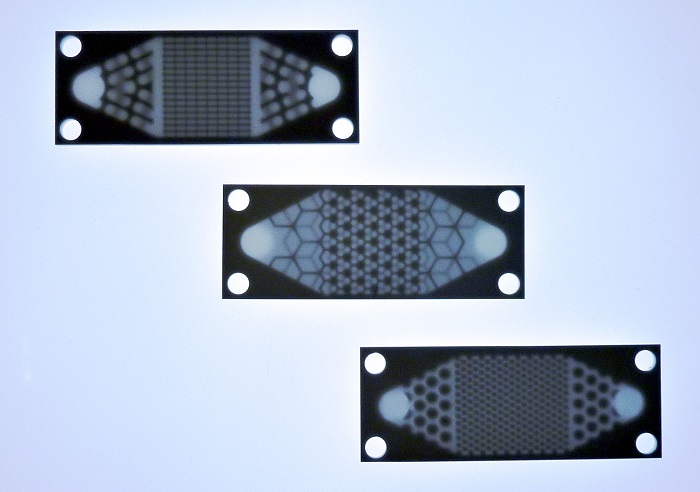

The geometric structuring of ceramic green sheets by punching, laser technology and embossing enables the integration of channels, reaction chambers and mixer structures in a monolithic ceramic body. This allows for the production of ceramic-based miniaturized chemical reactors. Besides the complete production line for LTCC/HTCC, Fraunhofer IKTS has the possibility for simulation (analytically, numerically) and constructive interpretation of the fluidic reactor structures. Ceramics offer a number of advantages for reactor systems because of their high temperature stability and chemical resistance. In addition micro-reactions can be precisely controlled by integrated heater structures and sensor elements (temperature, flow, pressure, pH ...).

Technical characteristics:

- Integrated channel structures and cavities with structure widths from 40 micron to millimeter range,

- Flow rate: a few µl/min to 100 ml/min (0.4 bar pressure difference),

- Implementation of heaters, sensor elements and optical windows for stimulation or process monitoring.

Services offered:

- Development of micromixers, evaporators and reactors for microfluidic applications,

- Design and layout of customized solutions and

- Manufacturing of Prototypes up to sample production.