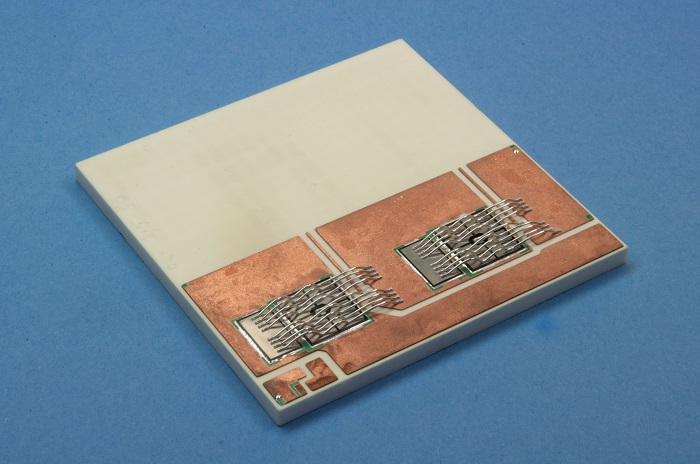

Cooling is a central need for power electronics. Thus, for example, in the operation of IGBT the power dissipation can be up to 100 W/cm. The used base substrates have to meet requirements both in terms of the highest possible heat conduction and heat resistance as well as in terms of their electrical insulation function. Instead of the application of monolithic ceramic substrates we use HTCC technology to integrate channels for liquid cooling in the ceramic body. This allows an active cooling close to the power-IC.

The integration of signal and power electronics for better modularization and simplification of the electrical and electronic architecture of electric vehicles using a combination of ceramic multilayer technology (LTCC, HTCC), high-density passive functions, direct copper bonding technology and integrated passive and active cooling is a challenging technology approach for novel components represent.

- Reduction of conduction loss,

- Monolithic integration of directed heat paths through highly thermal conductive materials in LTCC/HTCC in combination with fluidic convective cooling in the HTCC/DCB circuit board to achieve effective thermal resistance below 0.5 K/W (1 cm²).

The attractiveness of such ceramic solutions is based on compactness, robustness and weight savings of such designs, avoiding errors between plug, bond and cable connections, low electro-magnetic susceptibility and the resulting increase in operating safety.

Technical characteristics:

- Cooler sizes: 1x1 to 20x20 cm²

- Cooling capacity: <100 W/cm²

- Rth <0.5 K cm²/W

- Material: HTCC, LTCC

Services offered:

- Development of efficient cooling and heating structures for microfluidic applications in the areas of power electronics, medical applications or optical cooling systems (LED cooler)

- Prototypes up to sample production