Acoustic diagnostics – Defect detection | Signal evaluation | Quality assurance

Artificial Intelligence

Measuring and test devices have always had the purpose not only of displaying data and values but also of providing an interpretation and a meaning for the information displayed. Industry 4.0 is experiencing the emergence of test tasks of wider scope and greater complexity. The huge volumes of data generated by new measurement methods and different sensors often make interpretation difficult. Artificial intelligence (AI) is capable of assigning meanings to complex measurement data and assessing overall situations.

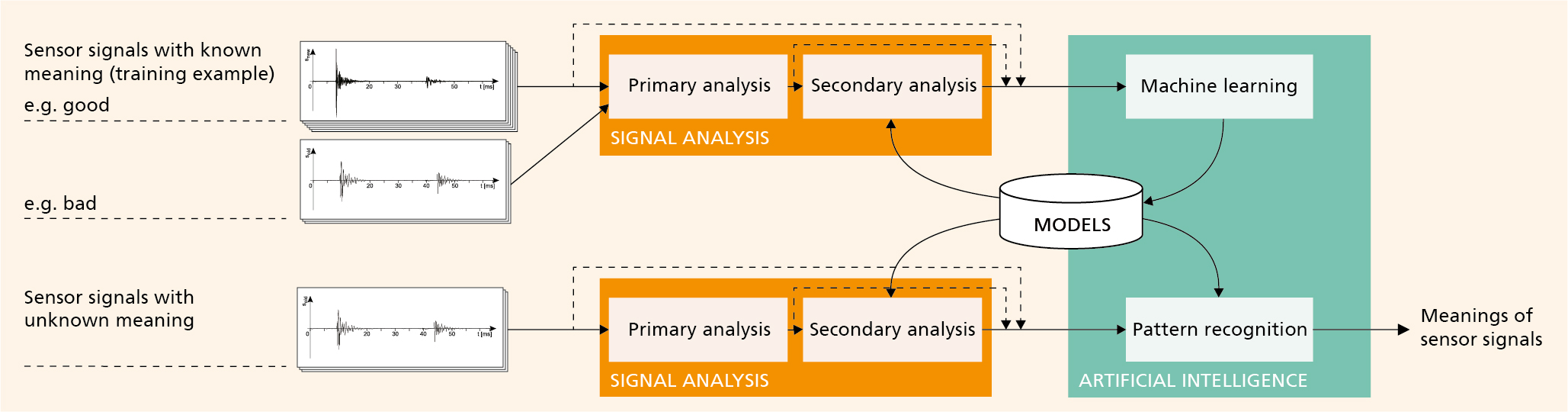

Fraunhofer IKTS offers a comprehensive range of state-of-the-art AI methods for automated evaluation of technical and non-technical processes. With the help of signal analysis, pattern recognition, and machine learning processes, sensor signals can be automatically interpreted and assigned meanings, e.g., “Test specimen good“ or “Component remaining lifetime at 20 %“. In the industry 4.0 era, humans no longer perform the task of interpreting data displayed by measuring instruments. Instead, they interact with and monitor AI systems. AI-based measuring and test systems learn the fundamental relationships between sensor signals and their meanings for their specific test tasks by means of examples prior to being used. Later on, they can be “supervised“ and corrected by humans in such a way that they can subsequently adjust and improve themselves in operation. This technology is much more flexible and powerful than traditional test methods are. Apart from the actual AI components, Fraunhofer IKTS uses established signal analysis technology. Primary analysis is essentially based on signal processing methods, including time-frequency transformations (STFT, WT, etc.), digital filters and filter banks, signal modeling (e.g., with optimal filters), and AI-based signal analysis (e.g., CNNs). Secondary analysis is performed to extract relevant information for pattern recognition from the primary features, e.g., by principal component analysis (PCA) or linear discriminant analysis (LDA).

Pattern recognition is based on, e.g., deep neural networks (DNNs), Gaussian mixture models (GMMs), hidden Markov models (HMMs), or support vector machines (SVMs) and includes interpretation of results. The class models required for this are built through special machine learning processes, such as deep learning (DNN), EM algorithms (GMM, HMM), and convex optimization (SVM). In a training phase, the system is supplied with training examples, or sensor signals with known meanings (e.g., “good test specimen“ or “bad test specimen“). Models can then be taught further (adapted) during operation for improving the AI system or adapting it to changed tasks. In certain DNN configurations, the pattern recognizer assumes the task of secondary analysis, as well as primary analysis in part.