Zirconium carbide – high-temperature material for high technologies

Current research

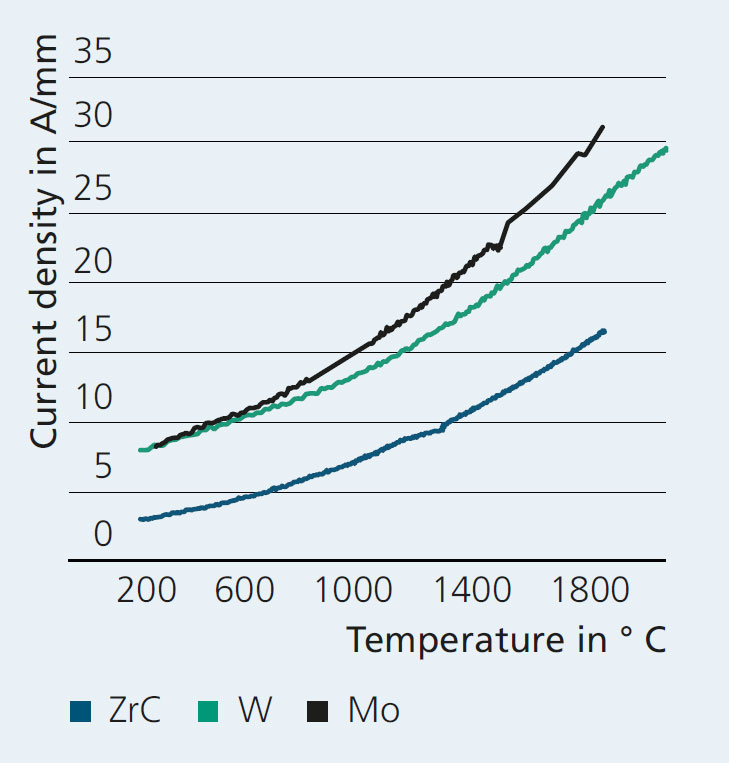

At Fraunhofer IKTS a technically practicable and inexpensive method to produce high-quality zirconium carbide ceramic materials has been developed. Due to its very high melting point (3540 °C) and its very low vapor pressure (<10-6 mbar at 2000 °C), zirconium carbide (ZrC) is an outstanding high-temperature and high-vacuum material on par with the strategically critical tungsten, tantalum and molybdenum materials.

Up to now, zirconium carbide has mainly been used in nuclear energy technology. Until now, compact ZrC components were not economically attractive for other applications. The IKTS development of pressureless sintering of ZrC opens new cost-effective processing options. Tungsten components provide an orientation on the potential uses of ZrC materials. Tungsten is a high-priced material which, due to its outstanding properties in high-temperature and high-vacuum technology, could not be replaced by any other material so far.

| Material characteristics of ZRC components (> 98 % of the theoretical density) | |

|---|---|

| Flexural strength / 20 °C | 350 MPa |

| Flexural strength / 1400 °C | 200 MPa |

| Flexural strength after annealing 1900 °C |

350 MPa |

| Fracture toughness | 4 MPa√m |

| Thermal conductivity / 20 °C | 31 W(mK)-1 |

| Thermal conductivity / 2000 °C | 38 W(mK)-1 |

| Spec. resistance / 20 °C | 1-10-3 Ωcm |

| Spec. resistance / 2000 °C | 2-10-3 Ωcm |

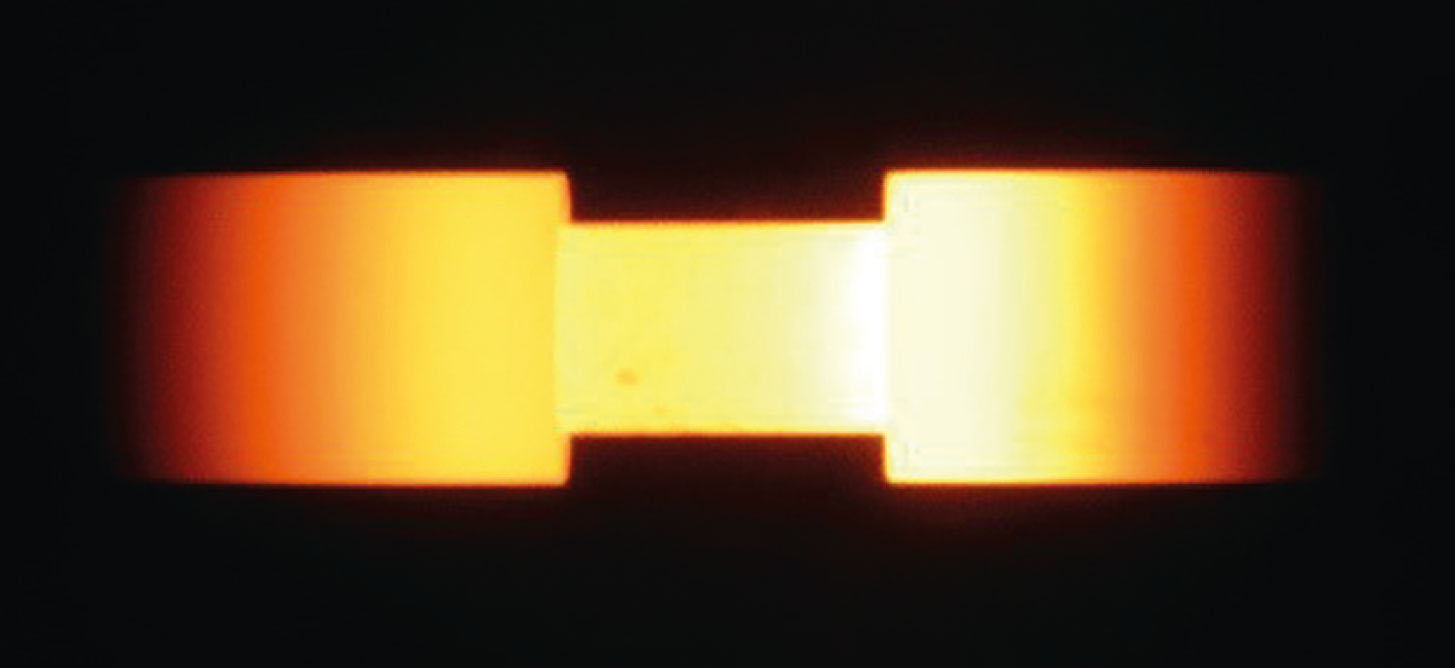

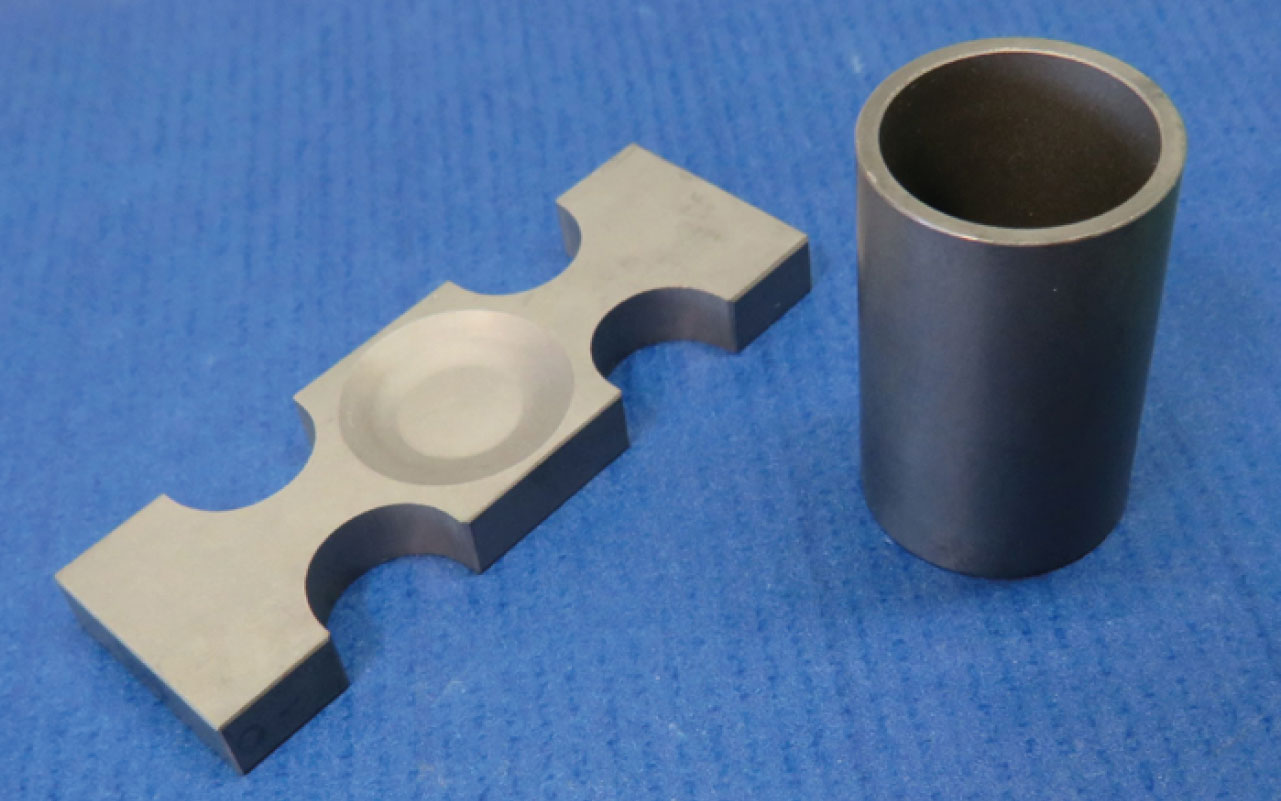

It combines properties such as corrosion resistance, chemical stability, maximum thermal load capacity (> 2000 °C), temperature change resistance, good electrical conductivity and mechanical properties such as modulus of elasticity, strength, fracture toughness over a wide temperature field. Only the combination of these properties enables the reliable and long-lasting function of certain system components, such as heating elements in high vacuum furnaces. The developed zirconium carbide materials can be used advantageously as a substitute for refractory metal components. Because besides their material characteristics, they are lighter, more cost-effective and contain no critical raw materials. Their application as heating elements and evaporation boats up to extremely high temperatures under vacuum has already been successfully tested in laboratory conditions (FKZ: 003VP05870). But also in other fields, such as semiconductor technology, photovoltaics, OLED, and nanoelectronics, zirconium carbide can bring its unique features into play. At the same time, the use of ZrC in the production of components in mechanical and plant engineering results in a significant reduction of weight and energy compared to refractory metals.

Services offered

- Manufacture of heating conductors in customer-specific dimensions

- Manufacture of kiln furniture

- Manufacture of targets and vaporizer accessories