Ceramic electrodes and cold plasma – a combination for efficient wastewater treatment

Current research

The purification of wastewater from industry and urban settlements requires new technologies and processes due to more stringent requirements with regard to water quality and the environment.

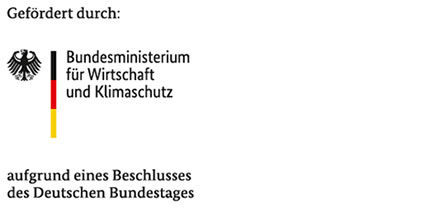

Cold atmospheric plasma technology may prove a solution for the challenging chemical and biological decontamination of water. Cold atmospheric plasma can be generated with simple technical equipment and in an energyefficient way. However, the technical components needed for this relatively new technique have not yet completely matured. Some of them require intensive service and frequent replacement, particularly for long-term use. In order to apply plasma in commercial wastewater technology, it becomes particularly essential to adapt the materials and design of the plasma electrodes, which work under high electrical and chemically-corrosive stress.

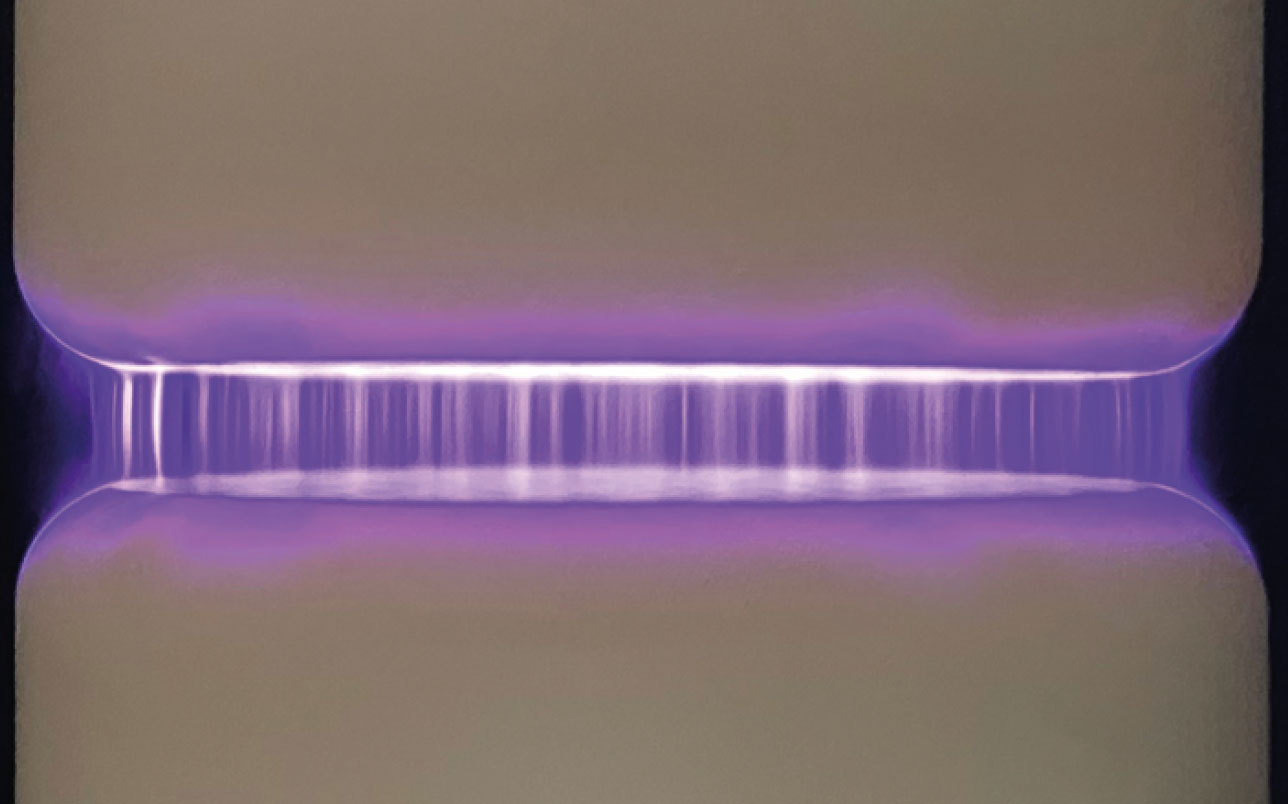

Ceramic solutions for plasma electrodes

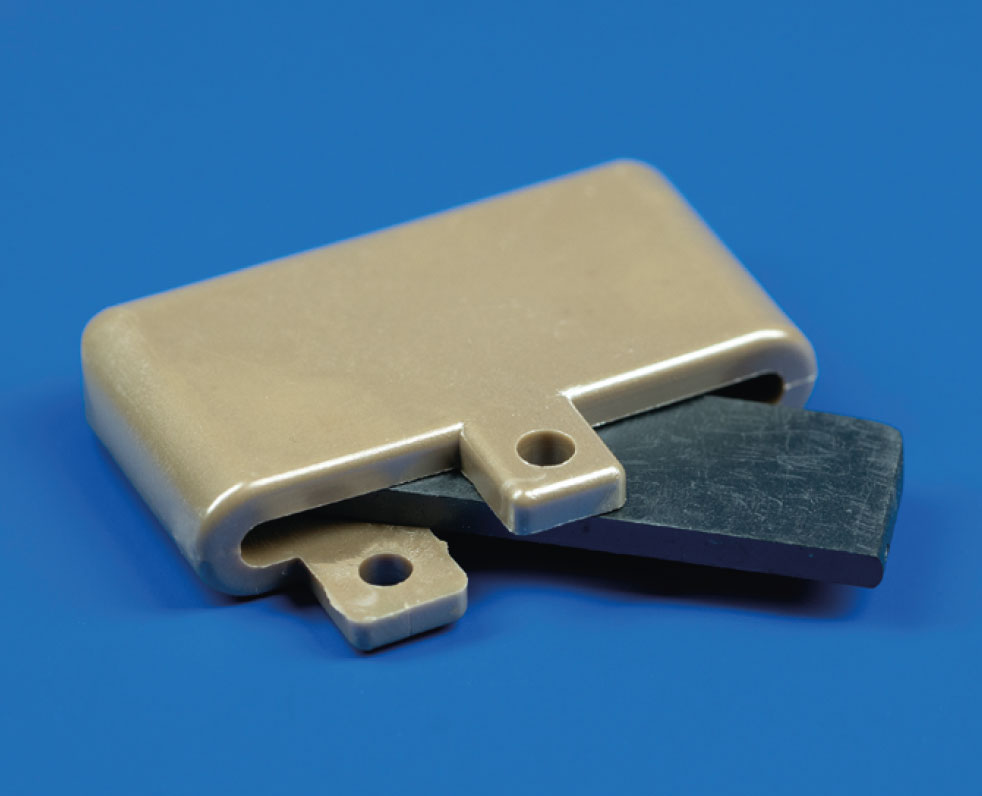

Plasma electrodes consist of two basic components – an electrical insulator and an electrical conductor. The insulator in particular determines the quality and characteristics of the plasma through its material properties. The plasma characteristics depend on the strength of the electrical field, the frequency and voltage. The electrical permittivity and the dielectric strength of the insulator make it possible to operate the electrode with extraordinary high electrical frequencies or high voltage levels. Extremely high electron temperatures can be reached within the plasma while the overall temperature of the gas is kept around 40 °C. Thanks to this phenomenom it becomes possible to use the high electron temperature to treat temperature sensitive materials against microorganisms or chemical substances. As a side effect, ozone (O3-) is generated. It efficiently neutralizes numerous harmful substances.

The use of plasmas for wastewater purification requires a redesign of electrodes, e.g. a combination with cellular or porous components. Alternatively, aerosol could be an option for supplying water into the plasma. So far, Fraunhofer IKTS has performed manufactural testing of titania-based ceramics as plasma electrodes. Their operational performance was successfully tested in cooperation with HAWK Göttingen (funding code: IGF 20546 BG). The results are promising. The generation of ozone, which can be considered an indicator of plasma efficiency, is superior to other ceramic and glassy insulator candidates. Ceramic insulators achieve much longer operating life compared with plastics. Consequently, service tasks on cold plasma devices can be reduced enormously in future.

Services offered

- Development of ceramic components for cold plasma systems

- Combination of plasma technology with wastewater technologies

- Electrical functional ceramic materials with high chemical and mechanical stability for wastewater technologies

Supported by