Zirconium carbide (ZrC) belongs to the class of metal-like ceramics. It has – like only few other materials – a very high vacuum stability of 10–6 mbar up to 2000 °C und is extremely heat-resistant (Ts > 3500 °C). Thus, it can be utilized as a highly refractory, i. e. thermally insensitive material.

ZrC offers an outstanding protection against chemical and thermal corrosion of plant components under non-oxidizing atmospheres. Despite this, it has been rarely used so far due to the technically demanding manufacturing of massive and dense ZrC materials. As soon as there is a cost-effective and reliable manufacturing technology available, this material will be an attractive alternative to conventional refractory metals in every respect.

A technology developed at Fraunhofer IKTS now enables, for the first time, the cost-efficient manufacturing of dense ZrC materials in various geometries through pressureless sintering.

When combined with an adapted powder processing route, this method even allows to manufacture large-scale components. The technology was registered with the German Patent Office (DE 10 2015 204 269).

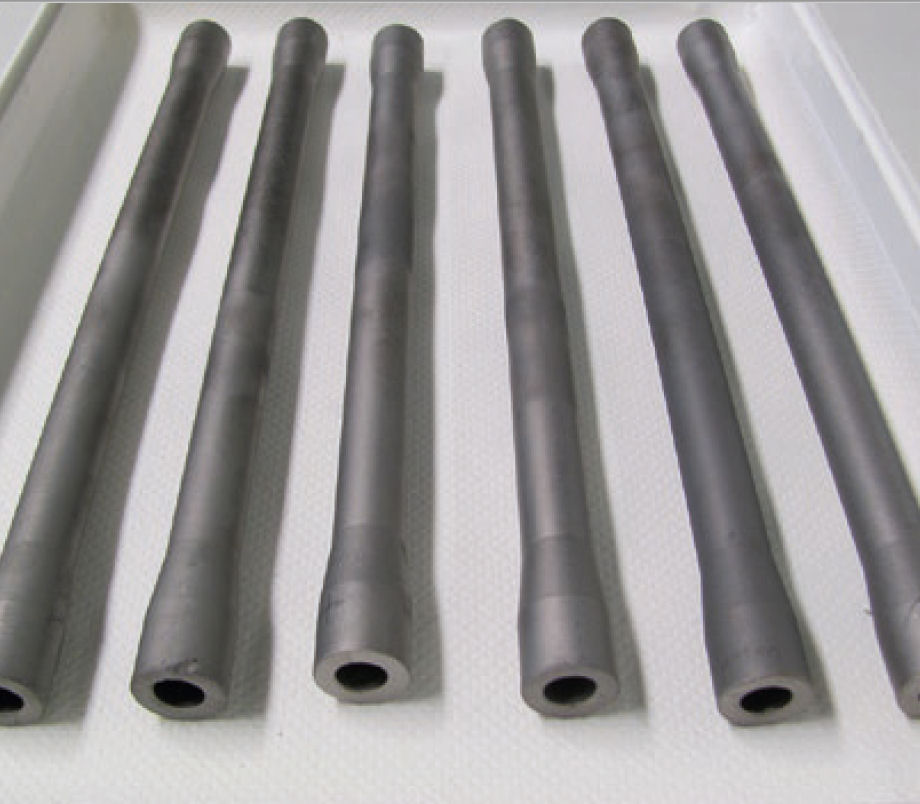

Tubes with a length of > 250 mm are the first components realized, but the production of plates and bars is also possible. These components can be applied as electric heat conductors, thermal protection, fluid lines or construction elements for high-temperature applications.

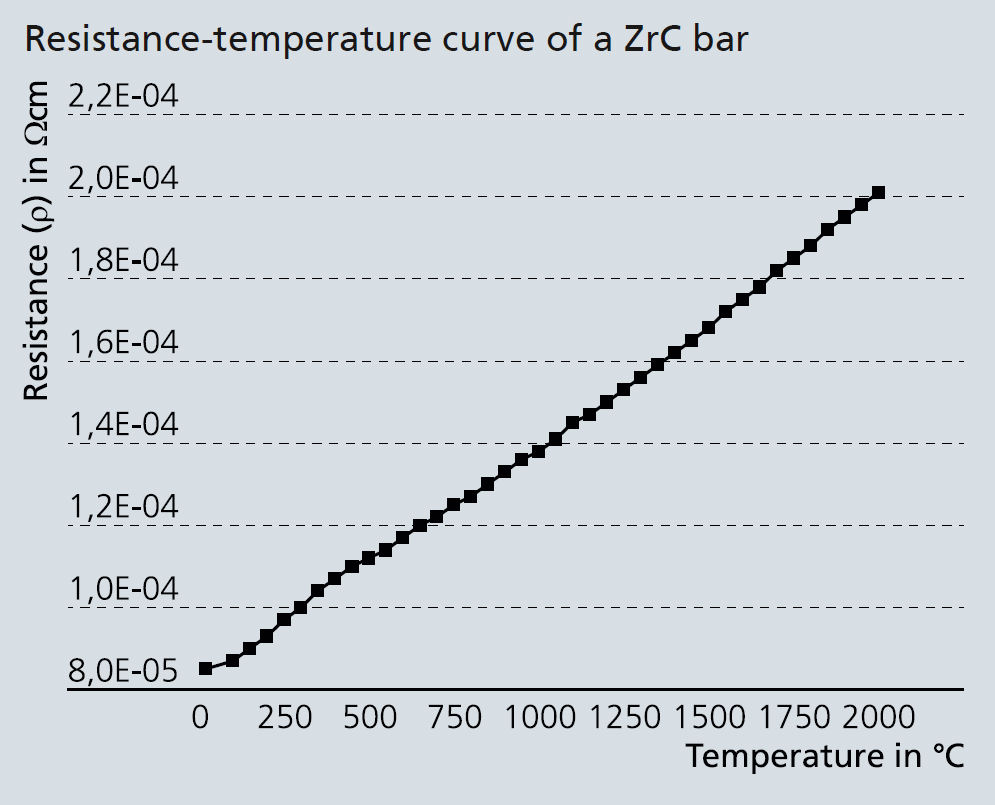

Tests so far have confirmed that the components have a stable electrical resistance up to 2000 °C, high thermal stability, high mechanical strength, as well as the fracture toughness that is typical for ceramic materials. The vacuum stability up to 2000 °C is currently being investigated in a new test stand.

Services offered

- Development and manufacturing of ultra-high-temperature

ceramics (UHTC) - Characterization of UHTC up to 2000 °C