Measuring dynamic fatigue in corrosive media

Current research

Testing ceramics under operational conditions

Ceramic components are high-strength and functionalizable, which makes them ideal as construction elements in the industrial environment. This requires new methods for the investigation of their long-term stability under real operational conditions. The fatigue behavior under dynamic load as an essential aspect of material selection and component design is especially of interest. Depending on load frequency and ambient medium, ceramic materials show different tendencies for subcritical crack growth resulting in different fatigue behavior. Current test methods usually focus on low-frequency load scenarios up to 20 Hz. Thus, tests with a high number of load cycles above 108 become very costly and time-consuming. In addition, unlike many metals, ceramics are also used in corrosive media. Current dynamic tests, however, often do not allow any variation of the ambient medium and therefore do not sufficiently consider this aspect of real operational conditions.

Automatic load test

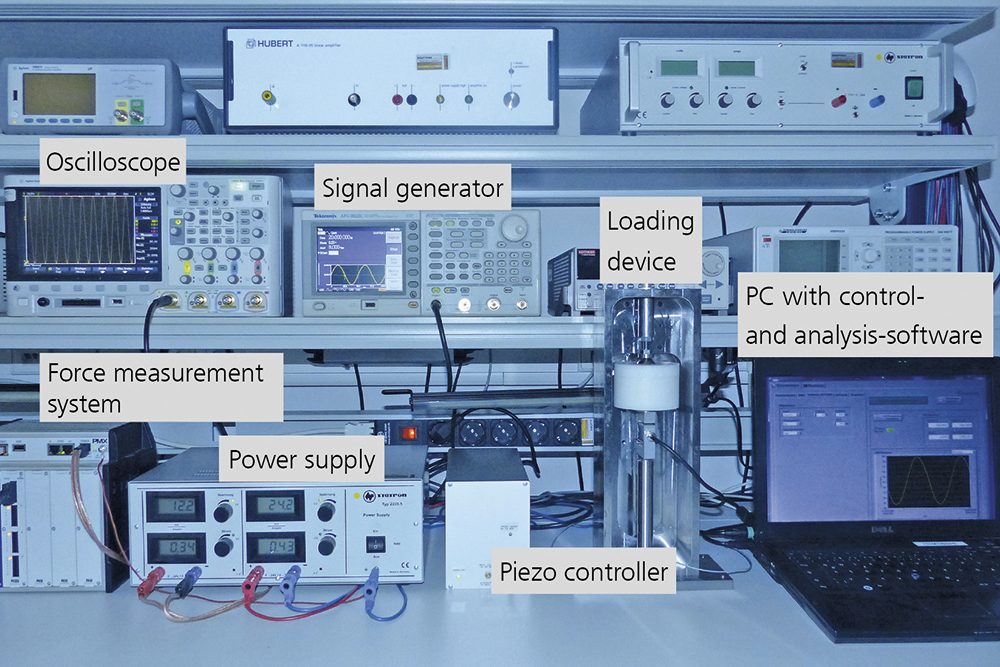

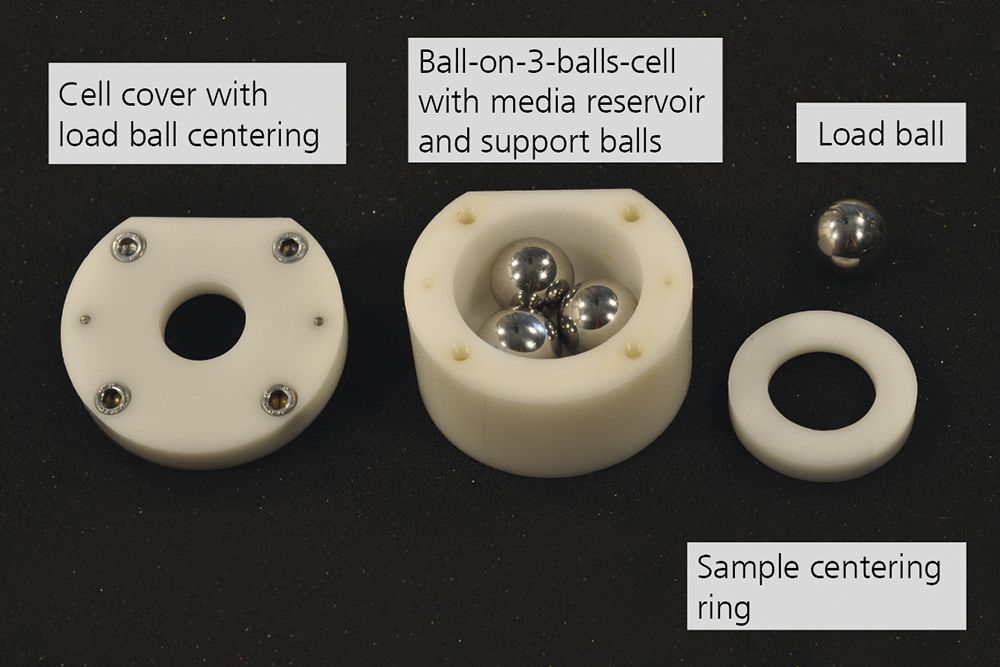

A new test stand developed at Fraunhofer IKTS now allows testing ceramic materials in corrosive media with dynamic loads and load frequencies up to 250 Hz and above. In conjunction with strength measurements and structural analyses, this enables a detailed and systematic investigation into the media- and frequency-dependent fatigue behavior of materials even at very high numbers of load cycles. The load scenario used is the established “Ball-on-3-balls” setup, which allows for sample testing without expensive and property-changing surface treatments. The setup is then immersed in a liquid medium. The modular design of the system facilitates the simple adaption of the setup to suit other standardized and customer-specific load scenarios. The entire test procedure is software-controlled on the basis of flexibly definable load parameters and termination criteria, so that the stand-alone continuous operation of the test stand including data acquisition is possible.

Independently controllable components for a static preload and a superimposed dynamic load can be defined as load parameters. In addition to an integrated logic for fracture detection of the sample and the maximum number of load cycles, definable corridors for static, dynamic and total load, as well as temperature measurement points are available as termination criteria. The functional verification of the system was carried out in endurance tests on SiC-bonded diamond materials in an aqueous medium. Investigations of the samples after 107 load cycles have shown the very high cyclic stability of the materials.

Services offered

- Testing of the fatigue behavior of ceramics

- Development of application-oriented test methods