Comparison of methods for herbicide removal from drinking water in pilot scale

Current research

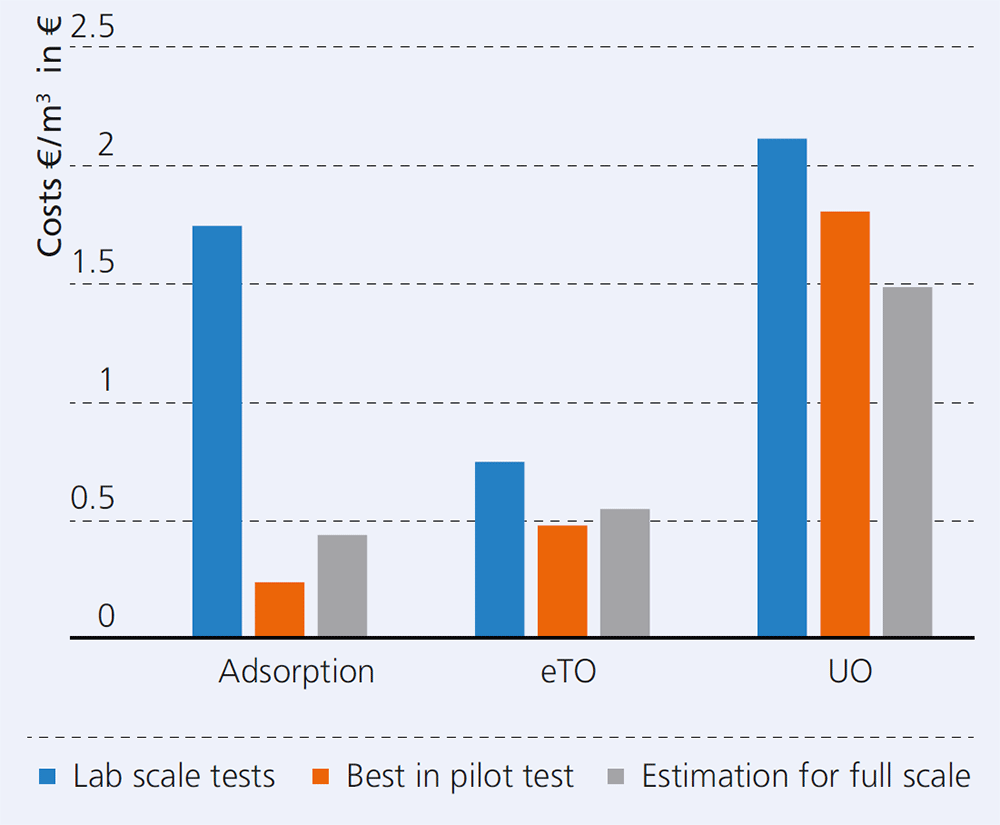

Pesticide and pharmaceutical residues in groundwater can impair the drinking water supply significantly and possibly lead to supply shortages. Sandy soils in particular are barely able to retain such substances. On behalf of mea Energieagentur Mecklenburg Vorpommern GmbH, the separation of the herbicide bentazone from well water was investigated by researchers at Fraunhofer IKTS and tested at pilot scale. This pollutant was found in concentrations of approx. 400 ng/l in the deep wells of a water supplier, rendering it unfit for consumption. Preliminary tests showed that the processes of electrochemical total oxidation (eTO), reverse osmosis (RO) and adsorption on activated carbon are best suited for herbicide removal. The eTO is the only process that offers the possibility to remove organic pollutants directly without pretreatment of the water, by oxidizing them to CO2. Reverse osmosis, in comparison, requires extensive preconditioning of the water, which leads to a high consumption of chemicals for de-ironing and softening as well as to large quantities of secondary waste. Adsorption on activated carbon is a simple, widely used technology. However, it is largely non-specific and carries the risk of germination and discharge of highly loaded particles from the bulk material. Subsequently, a modular pilot plant in container design was erected in the water plant and operated for more than 1000 hours (Figure 1 and 2). The throughputs were 30–60 l/h each. With all three processes, it was possible to reduce pollutant concentrations to the required target value of <100 ng/l in continuous operation. Accordingly, in this case, adsorption on activated carbon is the least expensive process, with costs of 0.24–0.45 €/m3 but this comes with the aforementioned limitations. Additionally, many trace substances are also poorly adsorbed on activated carbon. Bentazone can be destroyed by eTO at only slightly higher costs. The pollutant can also be removed by reverse osmosis but at significantly higher costs of >1.50 €/m3. In addition, the RO does not produce drinking water. In summary, the analysis shows that eTO processes certainly have the potential for wider use, as they are by no means associated with high costs per se.