There has been increasing public concern in recent years about the ongoing contamination of fresh and ground water by pharmaceutical residues. In addition to medical deposits such as antibiotics, waste resulting from pesticides has become increasingly problematic. Pesticides are easily washed out, especially from sandy soils, to reach ground and surface waters. In the case under investigation here, the contamination of the ground water by the pollutant Bentazon, a broadband herbizide, lead to the closure of a drinking water well with a rated capacity of 20 m3/h in a municipal waterworks.

Water purification processes in long-term trials

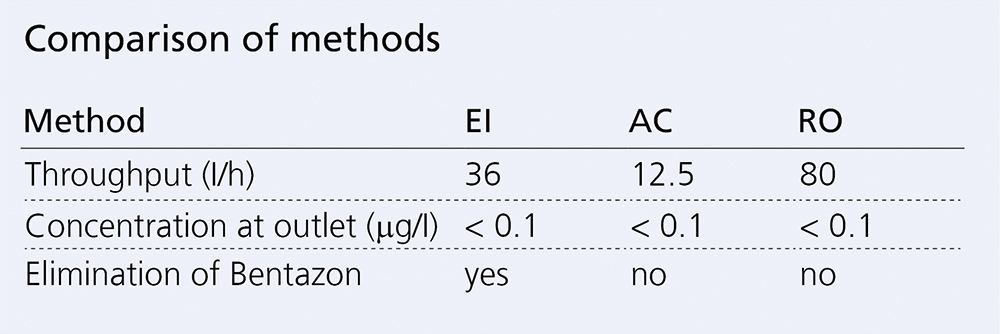

In order to prevent such drastic measures in the future, scientists at Fraunhofer IKTS examined and evaluated the efficacy of established technologies for the separation of Bentazon from well water: electrochemical incineration (EI), adsorption at activated carbon (AC) and reverse osmosis (RO). Oxidation by means of UV light, a method that had also been considered initially, proved to be unsuitable in preliminary tests. As part of this project, a pilot plant for the waterworks was specially planned and installed on site. Subsequently, all three methods were tested over a period of four months in continuous operation with a throughput of up to 80 l/h – partly as combined processes. All processes ran without failure. As the results (table) show, each of the methods is generally capable of separating the contaminant. Despite this, the real removal of Bentazon is only possible by electrochemical oxidation, which yields CO2 as the main product. With 0.5 kWh/m3, the energy consumption of the electrolysis is comparatively low.

The adsorption at activated carbon is also effective but for large-scale applications an additional pretreatment of the pumped water is needed, creating additional disposal costs. Reverse osmosis also permitted an almost complete separation of Bentazon. However, the treated water is desalinated so that it is no longer drinking water and has to be remineralized. More importantly, RO requires elaborate and costly pretreatment, such as deironing and softening by ion exchange. In addition, large amounts of concentrates are generated, which amount to approximately 25 % of the feed water stream and have to be disposed of.