The production of highly efficient solar cells requires front-side metallization with minimum contact resistance to the semiconductor and highly conductive conductor paths. Different technologies are investigated in conjunction with electrolytic processes.

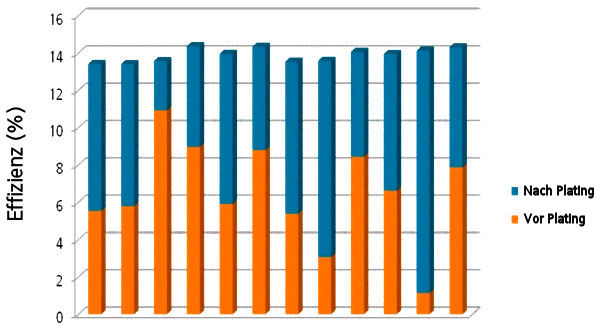

The galvanic reinforcement of screen printing layers is already used in an industrial context. The knack here consists in finding the best possible combination of a thick-film metallization and a suitable electrolytic bath to attain maximum efficiency and produce stable layers. The most important aspects are the adaptation and the suitable combination of thick-film metallization and the galvanic bath.

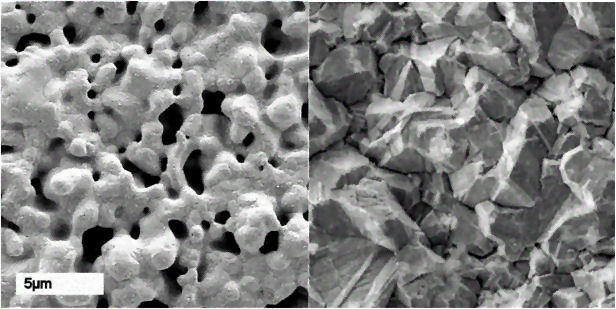

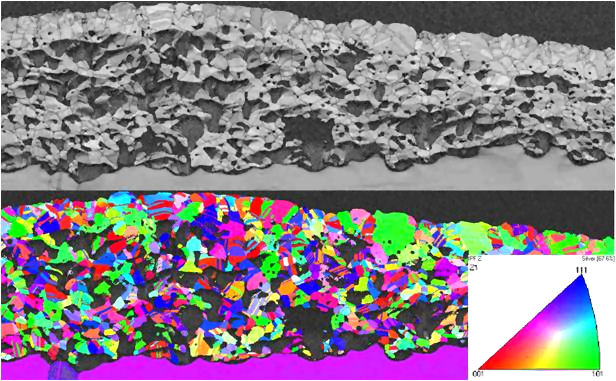

Different types of metallization can be combined if each technology has its own advantages to offer. One example is seed layers in aerosol printing, which were galvanically reinforced. In this way, a uniform level of efficiency across all cells is ensured. As an alternative, direct metallization of PV wafers with metal multilayer deposition from nickel-silver and nickel-copper-tin is developed.

Services offered

- Analyses on the interaction of thick film and electrolyte

- Adaptation of processes and bath to thick-film substrates

- Electrolytic reinforcement (silver, nickel, copper, tin) on seed layers