Functional oxide layers can be manufactured by electrochemical methods. Thin oxide film (5–30 nm) on valve metals like Ti or Ta are applied for capacitor applications. Again, thicker and porous anodic layers (2 µm–60 µm) for example on aluminum and its alloys are mainly applied in the field of corrosion and wear protection. Different properties and a wide functionality can be tailored by systematic variation of the anodizing parameters.

Services offered

- Producing of functional layers for corrosion protection by anodic oxidation

- Space- and time-resolved temperature measurement during anodic oxidation

- Optimizing of process parameters

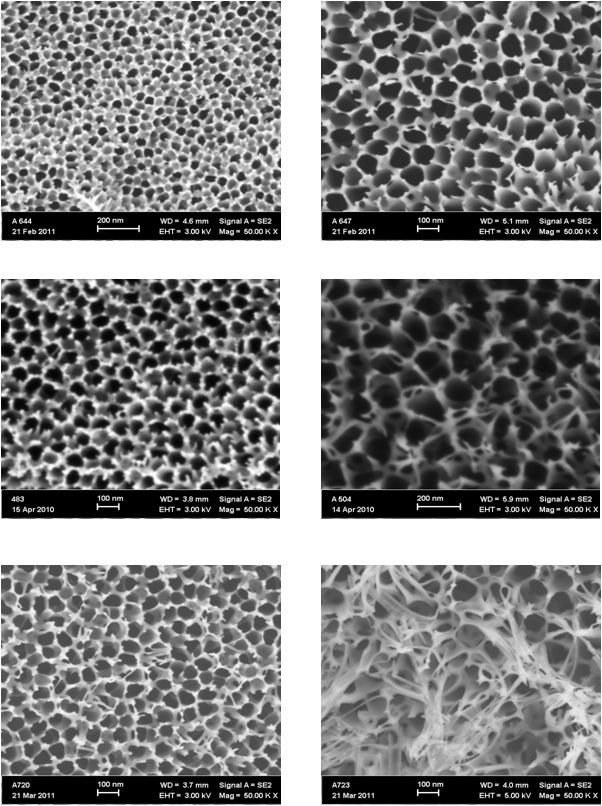

- Investigation of surface morphology and layer composition by FESEM

- Locally-resolved electrochemical measurement by micro capillary cell technique

- Investigation of the corrosion resistance

- Electrochemical analysis by cyclic voltammetry and impedance measurement

Equipment

- Anodizing equipment with two 18 liter baths plus alkaline etching and pickling baths, dipping- and rinsing sink (max. 300 V, 10 A)

- 200 V (1 A) potentiostat for investigation of the anodic process

- Micro capillary cell in combination with polarized microscopy and electrochemical potentiostatic system Reference 600

- Extensively equipped laboratory for electrochemical analysis