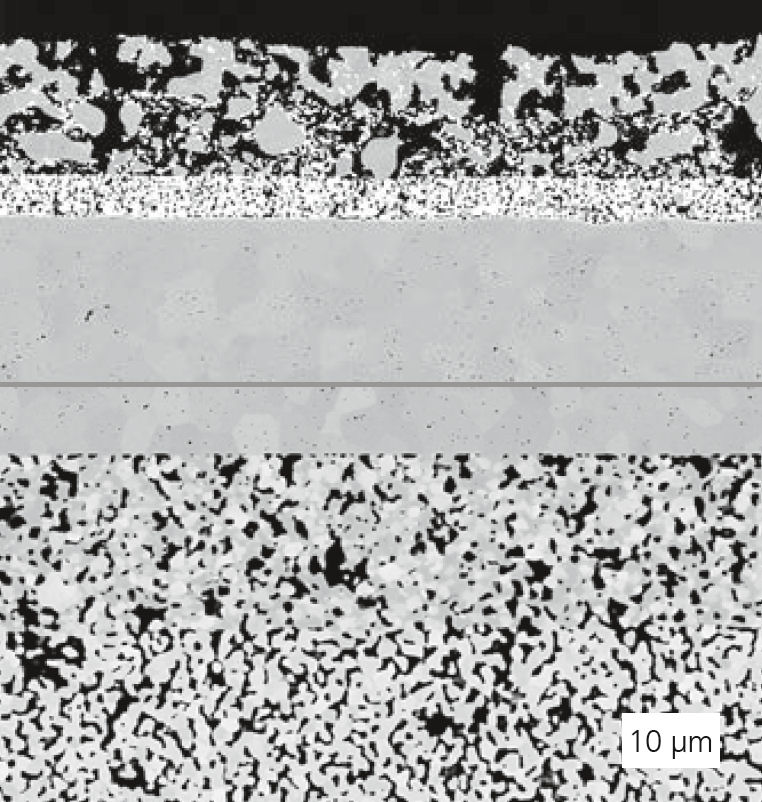

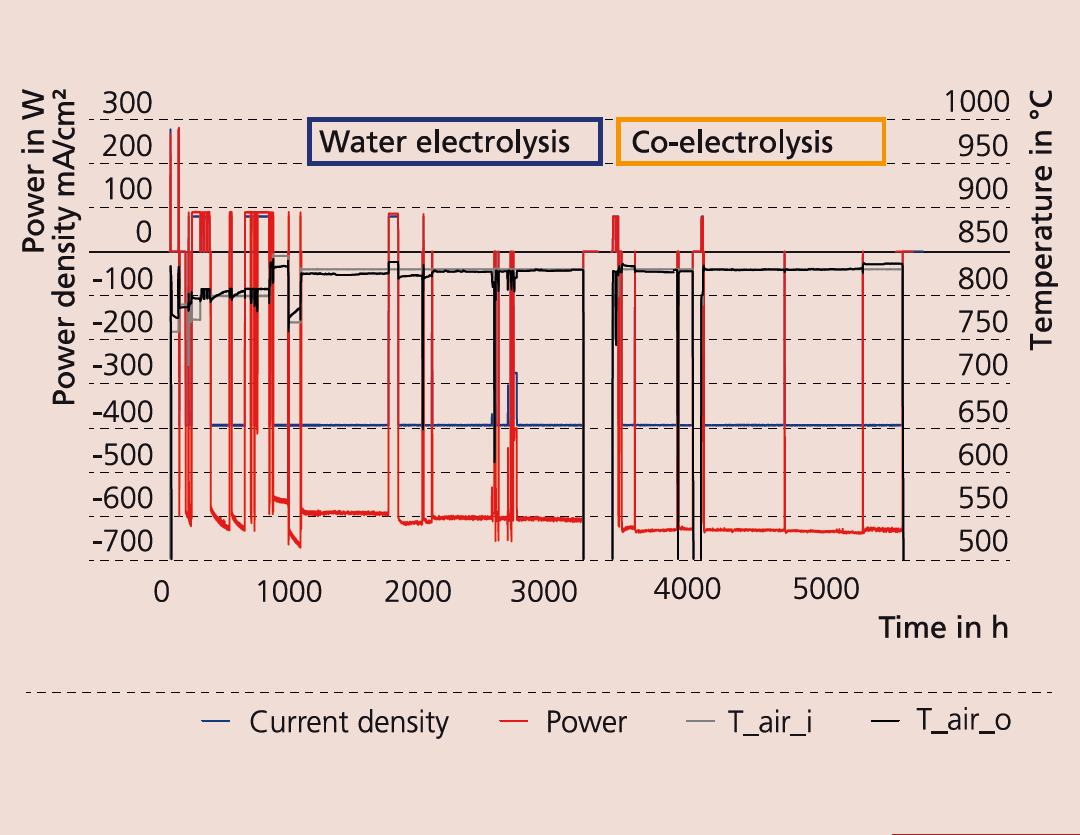

The production of synthetic hydrocarbon fuels through the co-electrolysis of steam/CO2 mixtures using renewable energy has been presented as a promising solution to reduce problems related to hydrocarbon consumption. The possibility to recycle CO2 into chemicals and value-added fuels helps to reduce the accumulation of atmospheric CO2 and realize the carbon-neutral cycling of fuels. The solid oxide cells have great potential within this field and can be used to convert steam/CO2 mixtures into syngas at high temperatures above 750 °C, followed by a Fischer-Tropsch conversion using excessive electricity, allowing to produce any desired carbohydrates. However, as process efficiency decreases with CO and CO2 present, it is important to select the right electrode materials and operating conditions. Fraunhofer IKTS has investigated the electrochemical performance of the electrolyte-supported cell with standard IKTSG3 electrodes for use as SOEC and SOFC over a wide range of operating conditions, varying the ratio of H2O:H2 and CO2:CO, operating temperature (750–850 °C) and current. The ASR of IKTSG3 cells at 850 °C and 800 °C are 0.178 ± 0.010 Ωcm2 and 0.286 ± 0.013 Ωcm2, respectively. In the performance test above ~ 4.000 h the cell resistance increased only by ~ 5 mΩcm2/1000 h (DP/P0 < 0.5 %/1000 h). Based on the results of electrochemical and microstructural analysis, the electrodes were additionally optimized for co-electrolysis operation to avoid anomalous increases of the working voltage during the first 50 to 100 h of operation. The new cell (IKTSG5), with an additional layer between the substrate and the multilayer air electrode as well as an optimized microstructure of both electrodes, was successfully realized and tested. The calculated linear power degradation rate for co-electrolysis mode over the complete durability test was about DP/P0 = 0.4 %/1000 h. Subsequently, this new IKTSG5 cell generation was integrated into the robust MK352 CFY stack design of IKTS and tested in steam and co-electrolysis operation. Across a wide range of applications, the performance map of the stack shows only a tiny difference in electric power demand (less than 2 %) compared with water electrolysis. The stack durability (> 4000 h) was demonstrated successfully with the new cell generation. The next step will be to demonstrate the production of various hydrocarbons by coupling the SOFC stack with a Fischer-Tropsch reactor, which will pave the way for storing excessive renewable energy and enable the CO2-neutral production of high-value chemicals.

Services offered

- Cell development and technology transfer

- Test of stack components for SOFC/SOEC under real operating conditions

- Development of stack modules for utilization in SOC systems

- Sale of SOC stacks and modules