Microprocessors and electronic devices are highly complex structures made of numerous materials with specific thermal and mechanical properties. Different thermal expansions during manufacturing and operation can lead to crack formation due to mechanical stresses and subsequently to the failing of the device. Therefore, it is necessary to characterize these materials and the influence of mechanical stress on the structures. A common method to apply stress is loading components and test structures with the 4-point bending (4PB) mode.

In-situ 4-point bending system

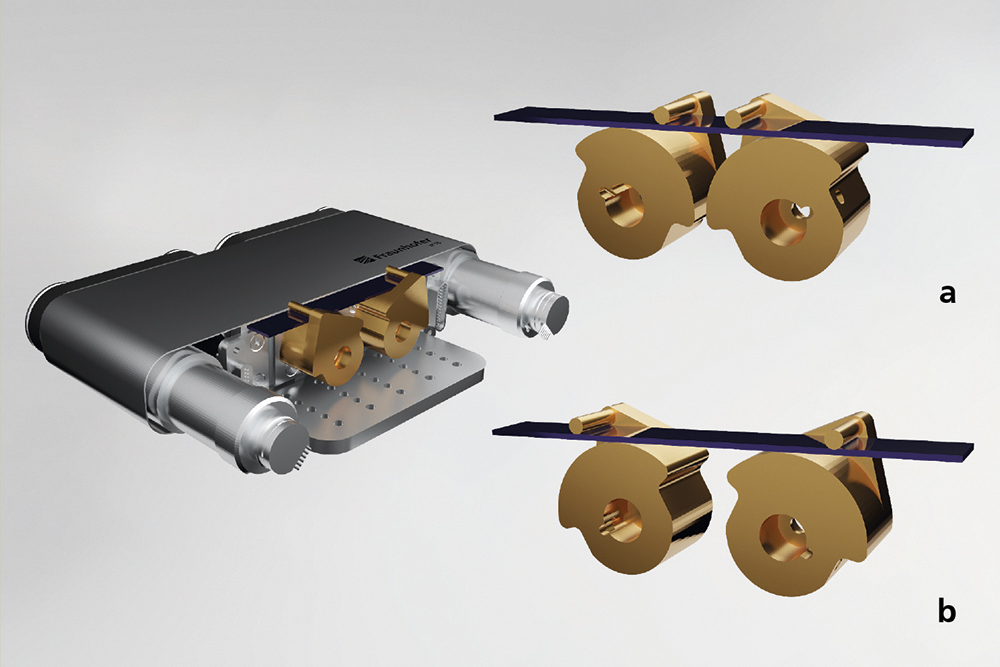

4-point bending is an often-used loading mode to bend beam-shaped specimens. The advantage of 4PB is the homogeneous bending moment between the inner support points. A novel 4PB device for in-situ scanning electron microscopy (SEM) was developed at Fraunhofer IKTS (Figure 1). One distinctive feature is the low height of the system, which enables use in closed and limited spaces, such as the vacuum chambers of SEM systems. Another unique feature is the ability to apply tensile and compressive stress on the specimen surface without changing the sample mounts. In contrast with standard 4PB devices, this is achieved by rotational sample mounts, which create the necessary relative linear displacement of the support points by eccentric rotation (Figures 1a and b). The mechanical stress on the sample surface can be determined at any point based on the knowledge of the sample geometry by measuring the actual torque on both sample clamps.

Flexible tool transfer

The tool can keep the bent state of a specimen due to the high 2 Nm holding moment even when powered off. This enables easy transfer to additional imaging or analytical tools. Hence, it is possible to conduct indentation experiments on a bent specimen, transfer the setup from the nanoindenter tool to an SEM, investigate the indents in the SEM and validate the applied mechanical stress with Raman spectroscopy.

Services offered

- Analytical measurements on clamped samples combined with SEM, nanoindentation (NI) or Raman spectroscopy analysis

- Correlated evaluation of the stress conditions of the sample with accompanying experimental techniques

- Customer-specific adaptation of the 4PB device on request