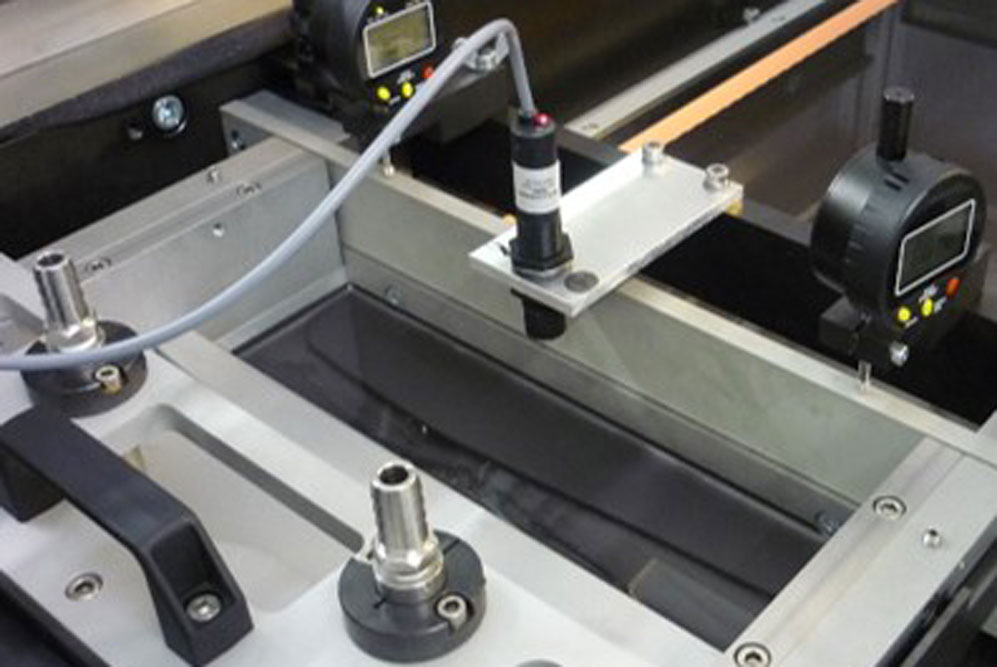

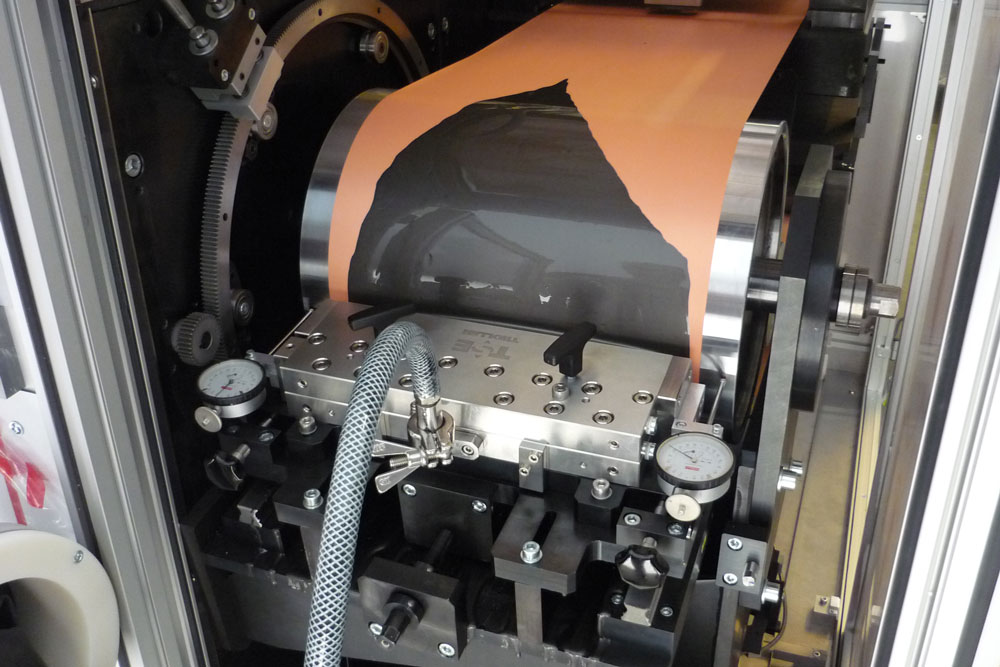

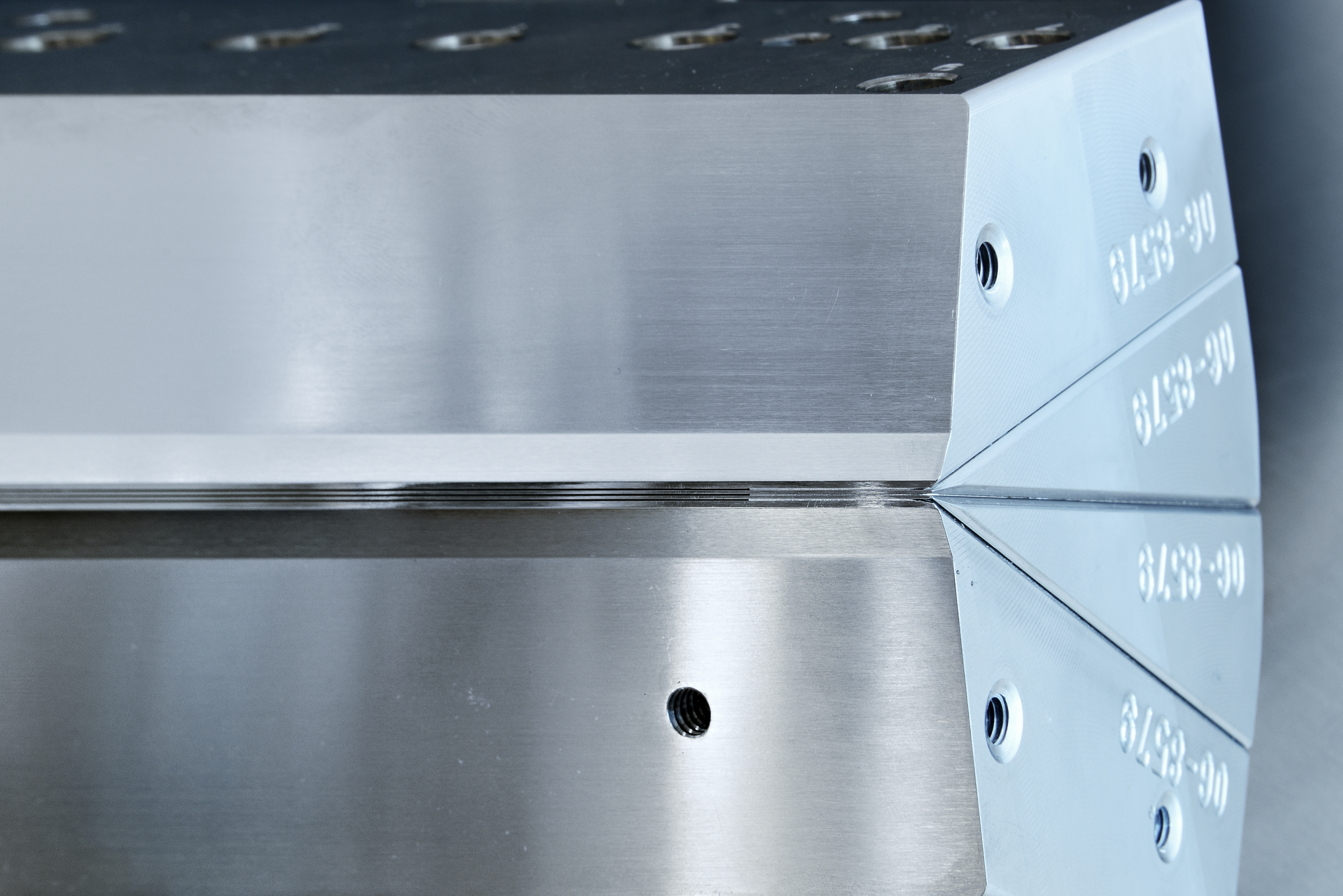

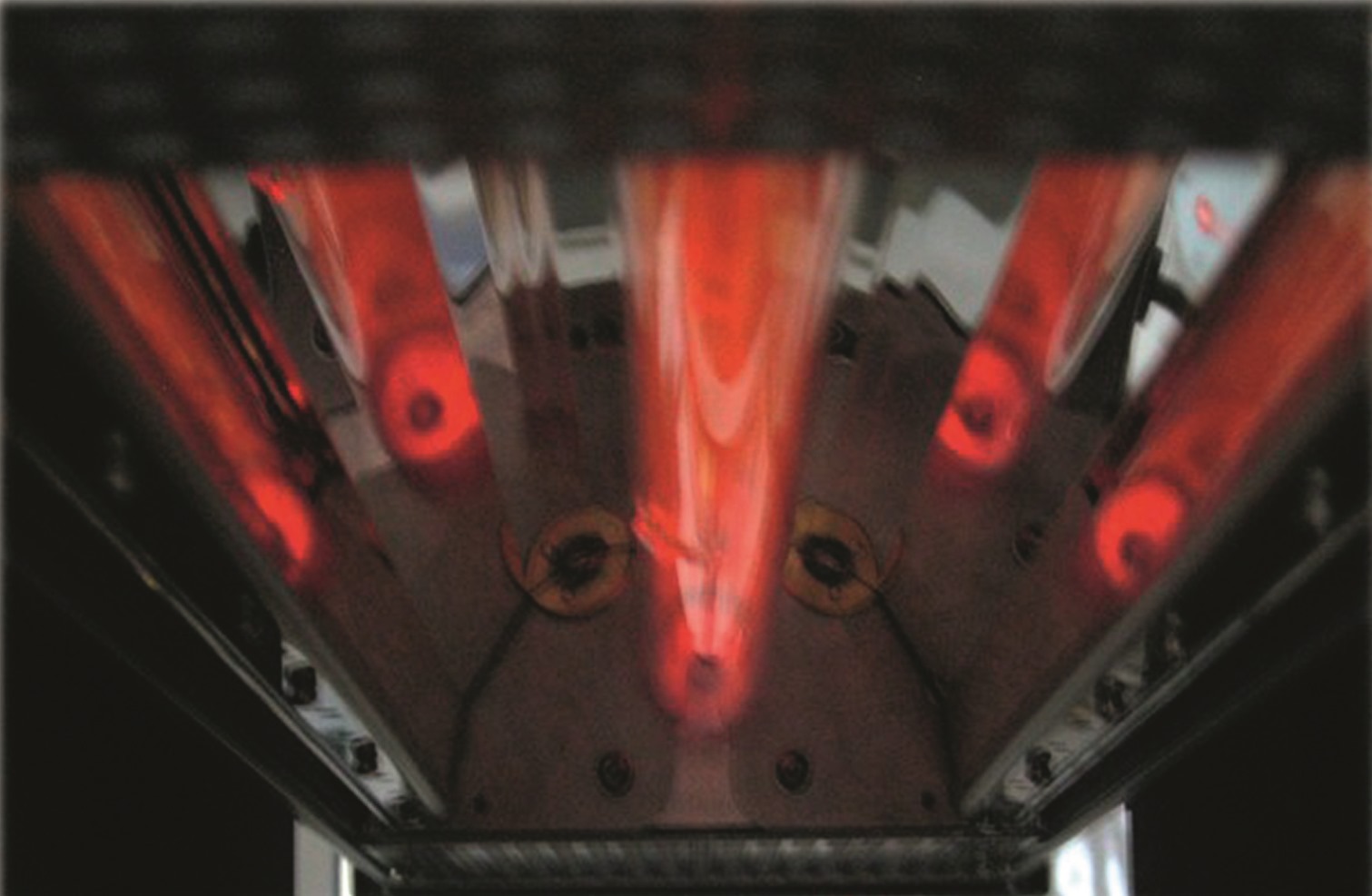

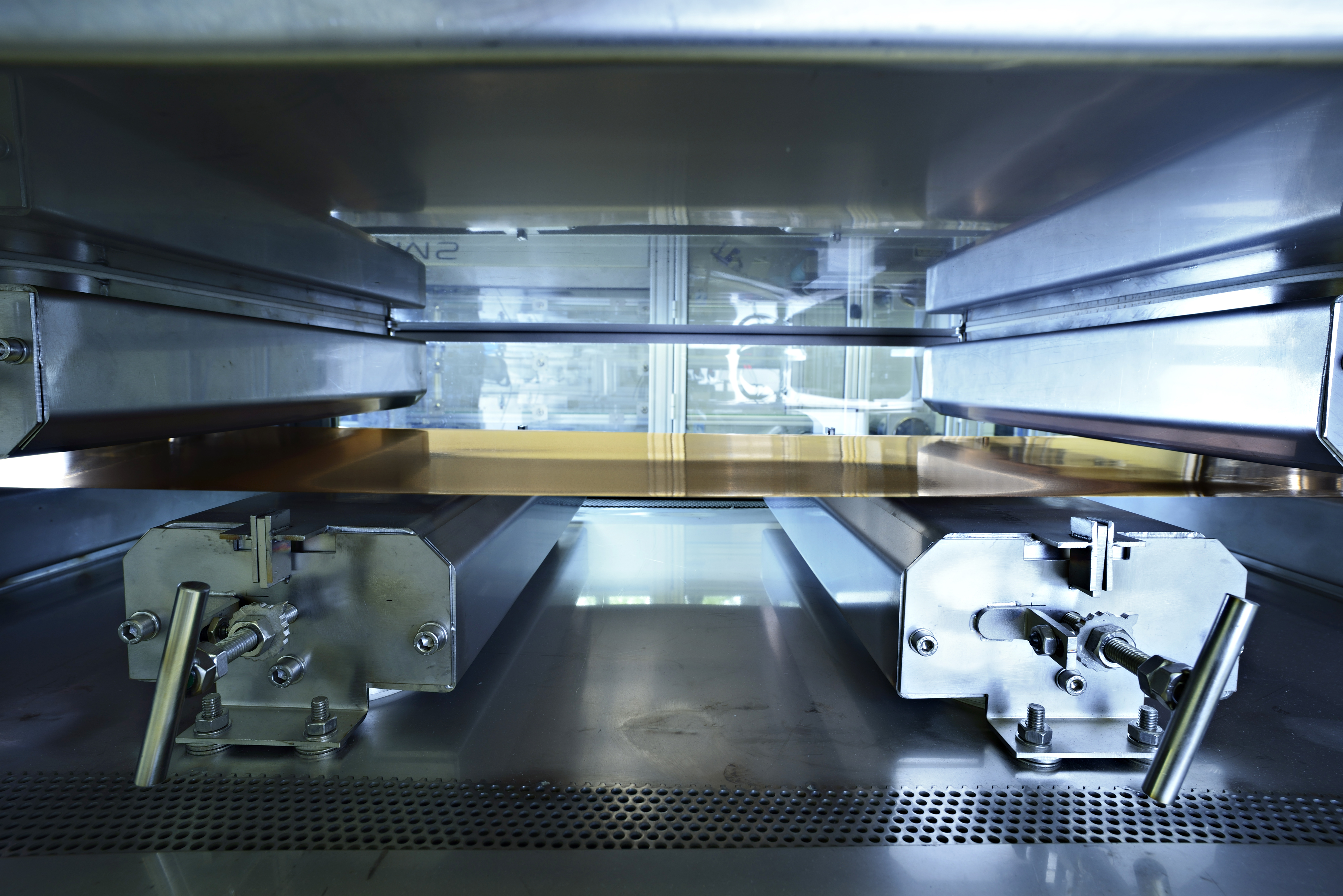

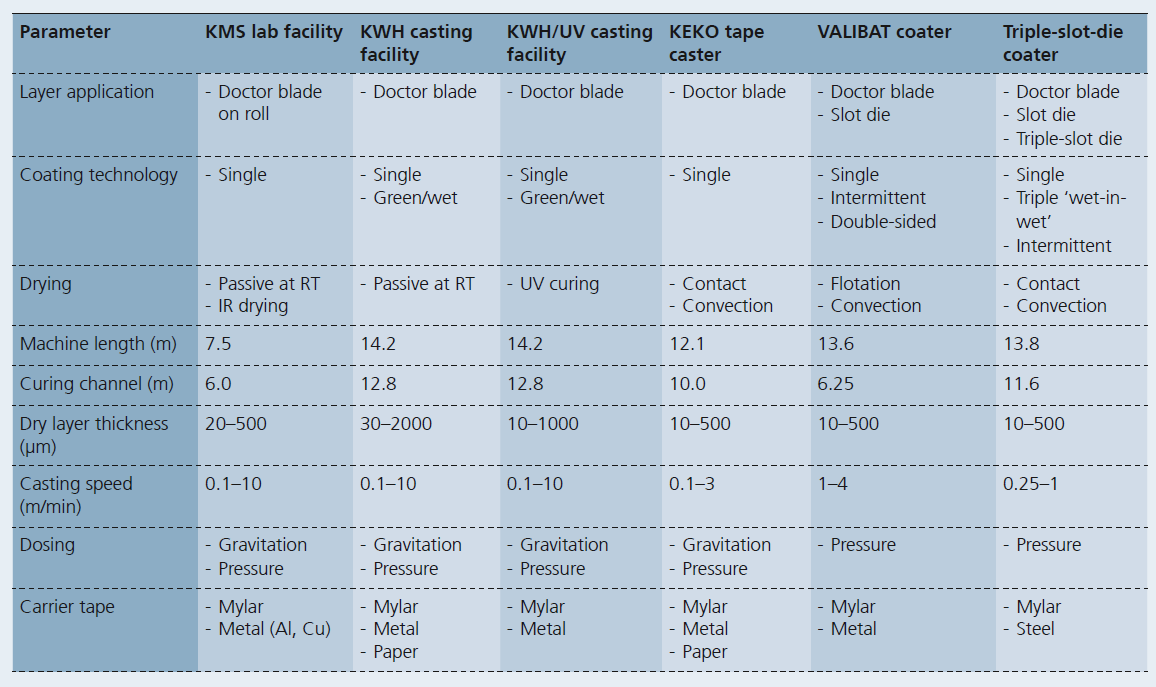

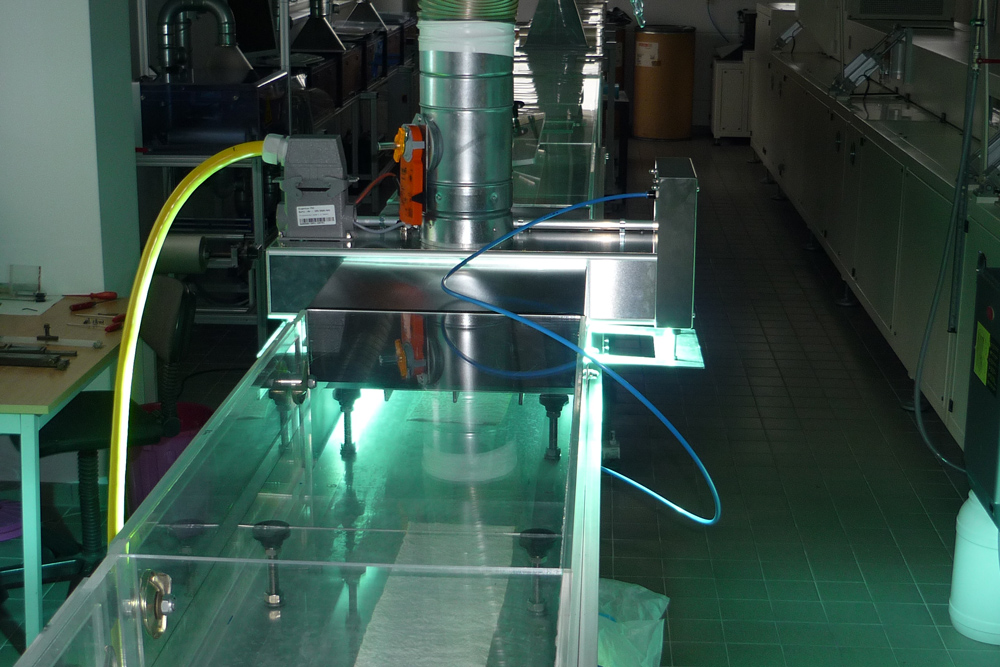

The Competence Center for Tape Casting Technology at the Hermsdorf site has five tape casting machines that implement different layer formation and drying methods. Three casting lines operate according to the classic doctor blade process. These lines differ in terms of line length, casting speeds and the drying principle (convection, contact, UV, infrared). The other two plants are based on slot die casting. Among other things, this allows innovative, modular and ecological tape casting concepts for Li-ion batteries to be realized or multiple layers to be produced in one process step using a triple slot die.

In the tape casting center, aqueous and organic tape casting slurry systems with viscosities in the range of 100 to 30 000 mPas can be processed. Both established tape organics such as polyvinyl butyrals and novel systems are used. The solids contained in the tapes have densities of up to 19 g/cm³ and average particle sizes from d50 = 200 nm to d50 = 30 μm. The applications of the tapes range from classical ceramic microsystems technology (LTCC, HTCC) to the currently strategically developed field of battery production, filtration and separation technology and a wide range of tapes for special applications.

The tape casting systems in the Competence Center Tape Casting Technology are also available to companies for carrying out their own test trials.