Innovative methods of packaging and joining technology are elementary for tape casting technology. In the end, they significantly determine the performance and load capacity of a component. The research group “Ceramic tapes” uses various printing and coating techniques to functionalize ceramic tapes as well as innovative joining technologies to assembly complete systems.

Services offered

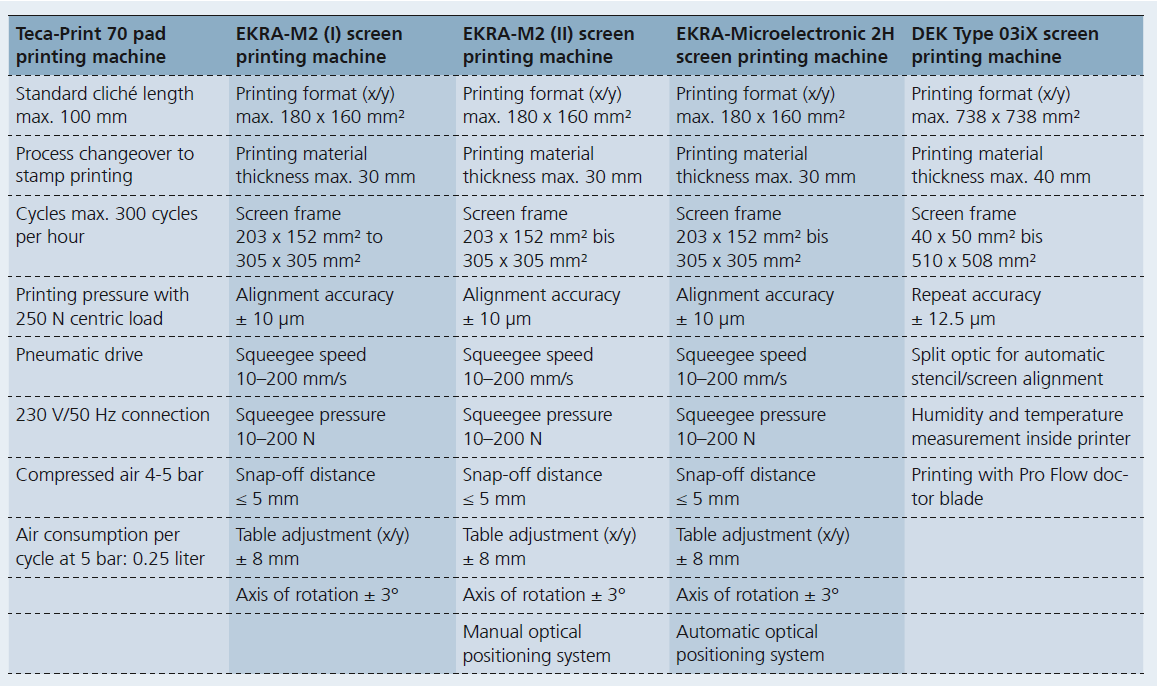

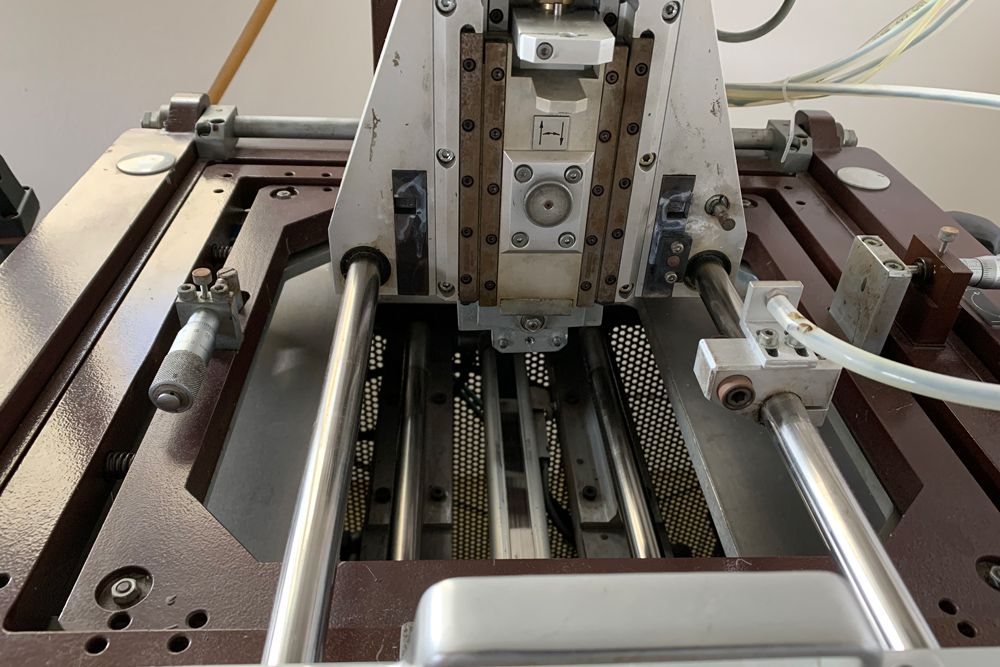

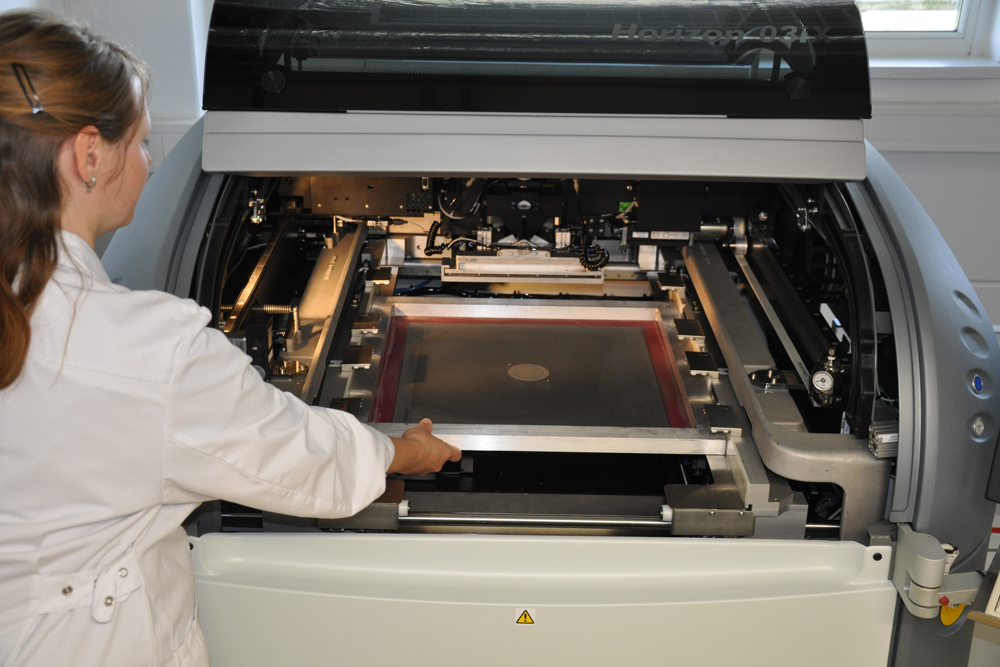

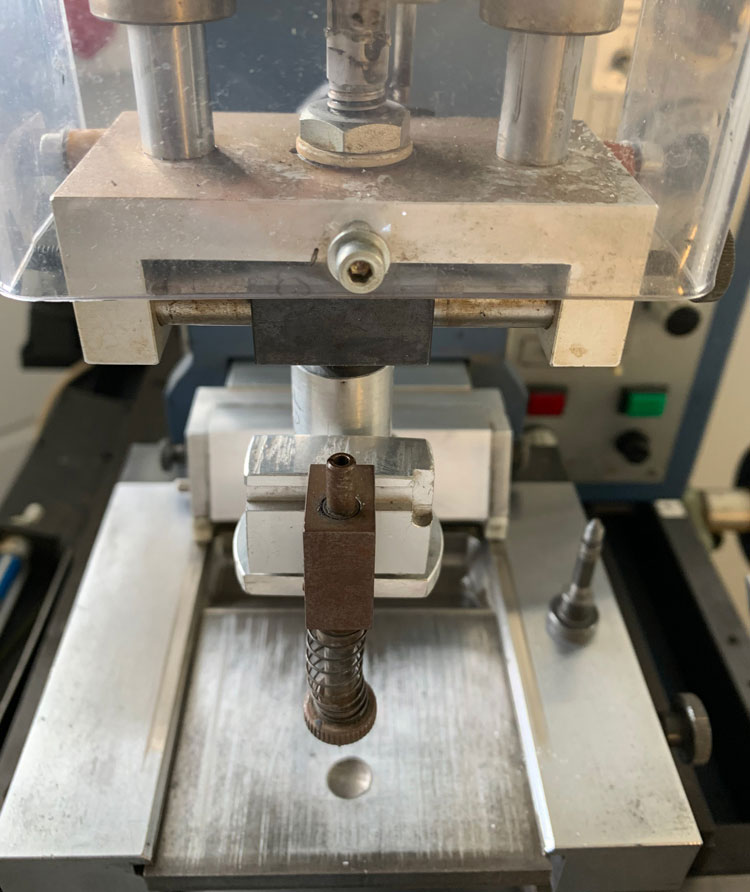

- Printing and coating techniques (e.g. screen printing, pad printing, 3D electrode internal coating) for the functionalization of ceramic green tapes

- Development of adapted special pastes (conductive, insulating and resistive pastes) for microsystems technology

- Development and production of electrical and electronic components and parts

- Joining of different ceramic components or metals

- Production of customer samples from laboratory to pilot plant scale

References

- Housings for sensors and reference electrodes with corresponding diaphragm

- Ceramic hollow fiber modules

- Internal metallization of electroceramic honeycomb bodies for self-regulating heaters

- Ceramic components for ozonizers, sensors for determining chemical and physical parameters such as pressure, displacement or angular position, temperature-stable pressure sensors for high and low voltage applications