Author: Annegret Kolarow

World Ocean Day 2021

Green at sea – alternative ship power in the fight against climate change

Overfishing, a plastic vortex in the North Atlantic over four times the size of Germany, illegal dumping of wastewater, deep-sea drilling, oil spills, underwater noise and much more – the seven seas are struggling with numerous man-made challenges. The oceans are both a source of life and a habitat, and they also store and transport heat, making them an important stabilizer of global climate. In an effort to bring responsible and sustainable handling of the world's oceans to the public's attention, the United Nations have proclaimed World Oceans Day. Every year on June 8, actions by governmental and non-governmental organizations aim to raise awareness about the threat to the sensitive oceanic eco-system, our role in this threat, and its impact on our planet.

Ceramic technologies at work for the oceans

It may not seem obvious at first glance: but as a ceramics institute, Fraunhofer IKTS has many touchpoints with the ocean. Only recently, a new research group of the Fraunhofer-Gesellschaft began its work at the “Ocean Technology Campus Rostock” (OTC), where IKTS is working together with three other Fraunhofer institutes, for example on technologies for analyzing and filtering pollutants in the ocean. Ceramic membranes are used in the treatment of industrial process water and in sustainable aquacultures – environmental technologies which have an impact not only on inland waters. IKTS researchers also accompanied a research vessel to the Great Pacific Garbage Patch to apply on-site analysis technologies of microplastics under real-world conditions. However, while the issue of microplastics has now reached the middle of society, there are other ocean-related polluters that have so far caused far less outrage.

Polluter Ocean Ships

Almond milk from California, tofu from Brazil, T-shirts from Bangladesh and cell phones from China: 90 percent of global trade is conducted by sea. In principle, shipping is considered a climate-friendly means of transport because it emits less harmful CO2 per ton of transported goods than road, rail or air. But this comparison falls short. Ocean-going ships run on bunker fuel, a waste product of gasoline and diesel refineries. It contains sulfur, phosphorus, heavy metals and other highly toxic substances that should essentially be disposed of as hazardous waste. As a cheap fuel, however, they end up in the tanks of ocean-going ships. This is not only a major problem in the event of a spill, because the ships' exhaust gases are also harmful to the climate, environment and health. Around 40 percent of the world's population lives near the coast and has to bear the consequences: according to one study, around 60,000 people die prematurely each year as a result of ship emissions. However, these are not covered by the Kyoto Protocol or the Paris Climate Agreement. Reason enough for the International Maritime Organization (IMO) to intervene: in 2020, the limits for sulfur emissions were reduced from the previous 3.5 percent to 0.5 percent. By comparison, the value for road traffic is 500 times lower. The IMO's ambitious target, which is still far too low for many island states directly affected, is to halve global ship emissions compared with the 2008 levels. High time, then, to talk about alternative ship power systems!

Of course H2 – The HyMethShip concept

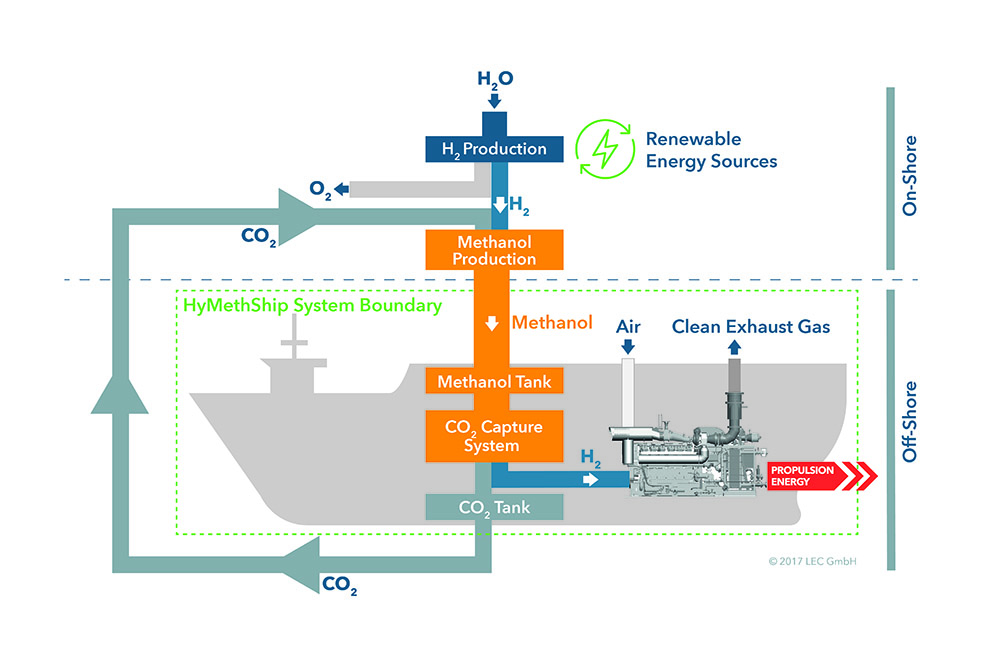

“The answer is hydrogen! What was the question?” At least that is how it seems in view of the current discussions about climate-neutral industry and mobility. The enormous potential of hydrogen as an energy carrier is undeniable, and at sea – H2O of course contains H2, it seems an obvious choice. But pure hydrogen has a transport and safety problem – it would have to be stored on board under high pressure in heavy steel containers. In the EU project "HyMethShip", an alternative has been found. Together with project partners, such as shipyard Meyer Werft, the engine manufacturer INNIO and the ship operator EXMAR, IKTS has developed a pioneering propulsion concept that integrates the main engine into a closed carbon cycle.

The idea: On land, the ship refuels with methanol, which, unlike hydrogen, can be stored without difficulty and does not pose a problem for the environment even if the tank were to empty completely in the event of an accident. On board, the methanol is converted with water by steam reforming. This process produces the required hydrogen, which is separated by a membrane (here lies the ceramic!) and drives the ship's engine by direct combustion. This process releases significantly more hydrogen than is stored in the methanol itself, since the water provides additional hydrogen. On the other hand, CO2 is produced, which is stored in tanks, pumped off on land, and used again for methanol production, thus closing the cycle.

Compared with conventional operation with bunker fuel, this propulsion system can save up to 97 percent of CO2 and almost all sulfur and particulate matter emissions. The project will expire at the end of 2021. A pilot plant is currently being equipped for test operation at Graz University of Technology. With software support, operation is being optimized and validated to determine whether the desired emission reductions and high system efficiency can be achieved simultaneously. The next step would be test operation in real conditions at sea. The project partners have already made initial contacts during presentations and introductions in the industry and are looking for additional players in the shipping industry who would like to take the HyMethShip concept further, optimize it and ultimately use it.

Underdog with high potential – green ammonia as energy storage and fuel

While hydrogen is currently the answer to almost every question, ammonia seems to be the answer to a question no one is asking. Known to many only for its use as a fertilizer, ammonia has long been a secret favorite among insiders for climate-friendly ship propulsion, however. In the German Federal Ministry of Education and Research (BMBF)-funded WIR consortium (WIR - Change through Innovation in the Region) "CAMPFIRE" and in the EU project "HiPowAr", IKTS is working with other European research institutions and stakeholders in the shipping industry to establish ammonia as a synthetic fuel without CO2 emissions.

The use of hydrogen is only “green” if it is produced from renewable energies, such as wind power – this is also where the ammonia projects have their starting point. Established paths of ammonia synthesis, using the Haber-Bosch process, are based on fossil fuels. In the future, ammonia will be produced decentrally and from renewable energy sources. The chemical formula of ammonia NH3 reveals it: hydrogen is also involved here. H2 production using oxide ion-conducting membranes via a solid-state electrolysis (SOEC) process from water vapor is particularly efficient. Together with air nitrogen, green ammonia can thus be produced anywhere from water, air and green energy. Direct synthesis of NH3 from water vapor and nitrogen with proton-conducting membranes appears even more advantageous because the entire process takes place in only one reactor. The process is easier to scale up and less expensive than the conventional Haber-Bosch method, and most importantly, it is free of CO2 emissions.

But why ammonia? Unlike pure hydrogen, which has to be stored and transported in special tanks under very high pressures, ammonia is already liquid at 8 bar and can therefore be easily stored and transported. Its energy density is comparable to methanol. Another advantage: at 200 million tons per year, ammonia is one of the most widely produced chemicals in the world – so the infrastructure for production and transport is in place. The aim of the projects is to use ammonia in internal combustion engines and gas turbines, to convert it directly into electricity in fuel cells, or to convert it directly into propulsion energy in novel membrane reactors. And the exhaust gases? If they are treated with selective catalytic reduction and added NH3, all that remains is water and nitrogen.

Decarbonized, emission-free maritime shipping seems possible. However, the development must also be accompanied by research into the safe transport of NH3 and possible countermeasures in the event of an accident. It will also be decisive whether large-scale industrial plants for the production of green ammonia can be operated economically.

Green maritime transport – not just a matter of research

The transport volume in maritime shipping continues to rise. Strategies, such as “slow steaming”, i.e. reducing the speed at which ships travel in order to cut fuel costs and emissions, are already being implemented, but they can only be a medium-term solution. IMO Secretary General Kitack Lim agrees:

"It will be difficult to achieve IMO’s 2050 GHG reduction ambition only through energy-saving technologies and speed reduction of ships. Therefore, under all projected scenarios, in 2050, a large share of the total amount of CO2 reduction will have to come from the use of low-carbon alternative fuels."

The researchers have many ideas and are working with shipping stakeholders to implement them. But for a sector that distributes 90 percent of global trade, consumers also have a responsibility. They need to ask not only whether their shampoo is plastic-free, but also whether it was transported sustainably.

Further information:

- Group "High-Temperature Membranes and Storage Materials"

- Current research: Green revolution on the high sea – EU project HyMethShip

- Research projects: HyMethShip, Campfire, HiPowAr

- World Ocean Day

Stay informed: You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.