ReWaMem – Project launched for the reuse of wastewater in textile cleaning

Due to climate change and longer periods of drought, natural fresh water resources are becoming increasingly scarce. Nevertheless, several billion cubic meters of water are used annually for production processes in the manufacturing sector. The resource-saving use of water, especially in industrial production processes, is therefore crucial. This is where the "ReWaMem" project, funded by the German Federal Ministry of Education and Research (BMBF) and led by the Kompetenznetzwerk Wasser und Energie e.V., comes in. Using the laundry and textile cleaning industry as a testing ground, the consortium intends to develop new technologies over the next three years that treat process wastewater in such a way that it can be fed back into the cleaning process as fresh water. The aim is to significantly reduce freshwater intake from rivers.

The ReWaMem project stands for "Recycling of laundry wastewater to reuse the wastewater by means of ceramic nanofiltration". It is embedded in the funding measure "Water Technologies: Reuse" of the BMBF, which aims to develop innovative technologies, operational concepts and management strategies for water reuse and desalination and thus contribute to a sustainable increase in water availability as well as to a sustainable water management.

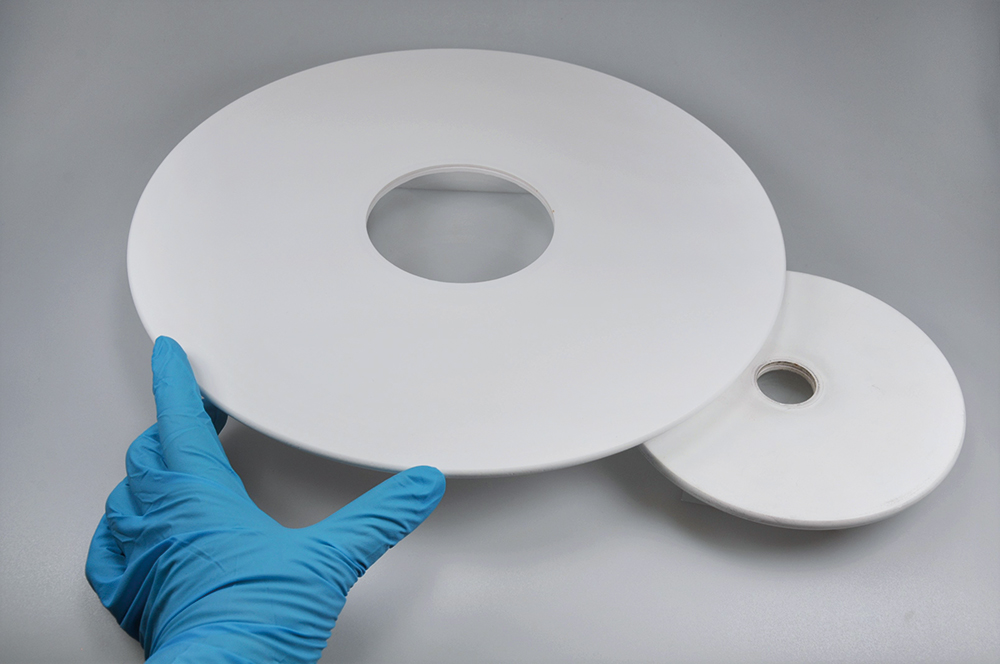

The industrial partner in the ReWaMem consortium is Coburger Handtuch- und Mattenservice GmbH & Co. KG (CHMS). The textile cleaning company has already successfully implemented water reduction measures on several occasions and has won environmental awards for its efforts. In the search for further ways to reduce water consumption, CHMS is participating in the project and making its own facilities available for pilot tests. For this purpose, the Thuringian companies Rauschert Kloster Veilsdorf GmbH and E.S.C.H. Engineering Service Center und Handel GmbH from Unterwellenborn are developing customized cleaning processes using ceramic nanofiltration, which will be integrated into the CHMS process flow.

As research partners, Hof University of Applied Sciences, the Fraunhofer Institute for Ceramic Technologies and Systems IKTS at its Hermsdorf site, and the Bavarian Center for Applied Energy Research e. V. located in Garching are working on the development of new technologies for the filtration and purification of wastewater, as well as methods to better determine the energy and resource requirements of the processes.

The customized solutions for recycling laundry wastewater can also be transferred to other industries where wastewater occurs. The project thus makes an important contribution to reducing the burden on our lakes and rivers.