Author: Annika Ballin

Printed electronics on tubes and 3D-printed parts – Customized efficiency for process and medical technology

Almost everyone has one: individually printed coffee cups. In the graphics sector, screen printing on round surfaces is firmly established, but in the electronics sector, it has so far only been a niche application. However, tubular screen printing and other new printing technologies, such as dispense jetting, promise significant increases in efficiency. Using optimally coordinated printing processes, thick-film pastes and ceramic substrates, researchers at Fraunhofer IKTS are printing highly efficient miniaturized heaters and sensors onto tubes and 3D-printed components, thus enabling completely new product possibilities for a wide range of applications. In doing so, IKTS is open to companies that want to use these technologies to significantly expand the functionality of their own products.

Thick-film pastes – a perfect fit for every application

For decades, heater and electronic components have been manufactured using screen printing or thick-film technology. In this process, the ceramic carrier is printed with a thick-film paste filled with ultra-fine metal particles and thus functionalized. Exactly where this paste is deposited on the ceramic surface, current paths are created. The composition of the thick-film paste defines the electrical properties. In this way, metal particles with defined electrical resistance can be produced for the manufacture of heaters, low-cost silver particles for the manufacture of solderable connection surfaces for LEDs, or chemically reactive layers as sensor surfaces for gas type detection.

In addition to the metal particles, the printable thick-film pastes contain other important components. For example, filler materials based on glasses or oxides ensure extremely strong adhesion to the ceramic, resulting in a gapless multilayer composite. It is important that the thick-film pastes are matched to the respective ceramic substrate material. Paste systems for alumina ceramics are particularly widespread, as these can be readily produced on an industrial scale.

Tubular screen printing expands range of applications

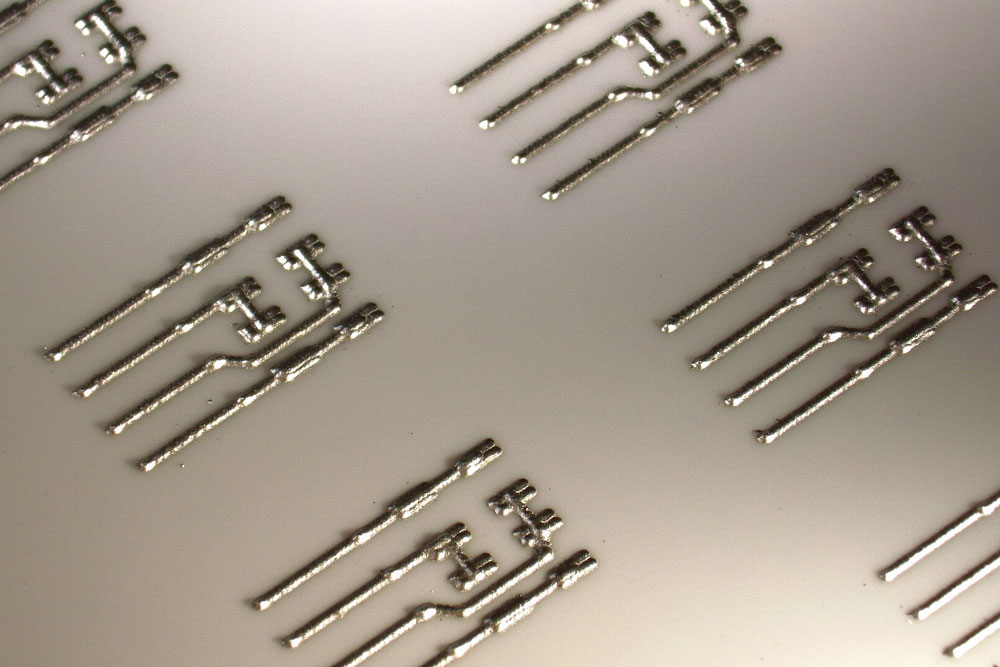

The production of planar thick-film components by screen printing is established worldwide because it is cost-effective and easy to automate. Several smaller individual components can be produced simultaneously on a commercially available ceramic plate. For many sensor or thermal applications, however, planar geometries are only suitable to a limited extent. This is because a rod, tube or 3D component geometry would often significantly improve system efficiency.

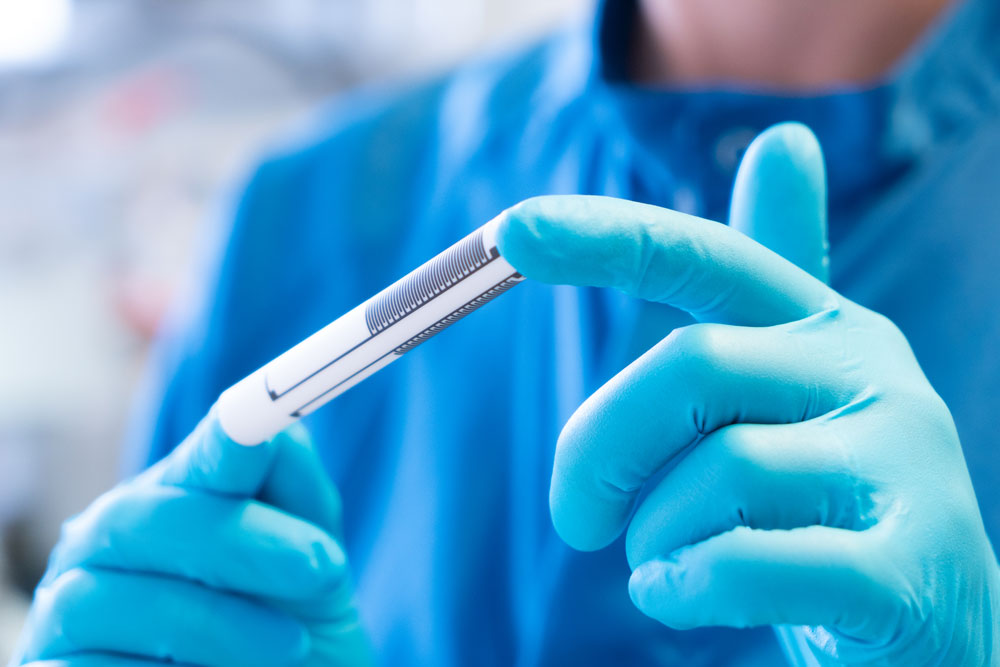

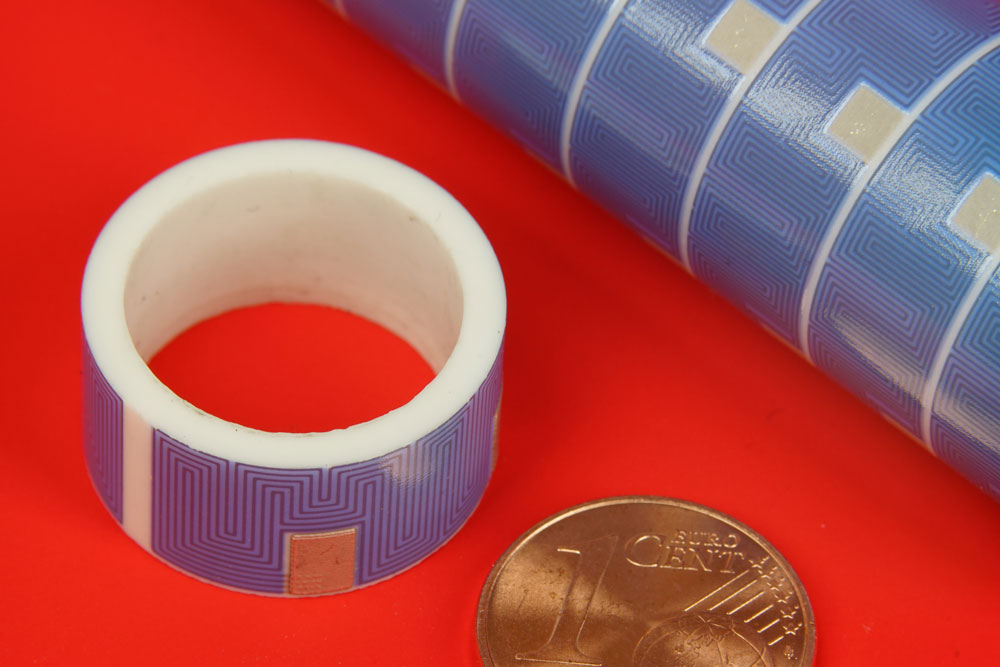

Fraunhofer IKTS is therefore working on materials and technologies that can also be used to functionalize tubular elements and even completely free ceramic 3D-printed bodies. In recent years, IKTS has built up extensive expertise in tubular screen printing on the smallest components with diameters of only 2 mm up to tube segments with diameters of 70 mm.

Tubular screen printing is particularly suitable for applications that require a greatly enlarged functional surface, such as heaters or sensors. In the case of heaters, a large heating surface usually has to be realized in a very small space in order to minimize undesirable heat dissipation. At Fraunhofer IKTS, tubular screen printing has already been used to manufacture efficient continuous flow heaters for a wide range of materials, miniaturized satellite engine elements and heating elements for PCR modules. In the field of sensor production, gas sensors are of particular interest. These are based on a large contact area between gaseous medium and sensor metallization. For example, highly efficient residual moisture sensors can be manufactured for gas-filled production lines.

Technological challenges

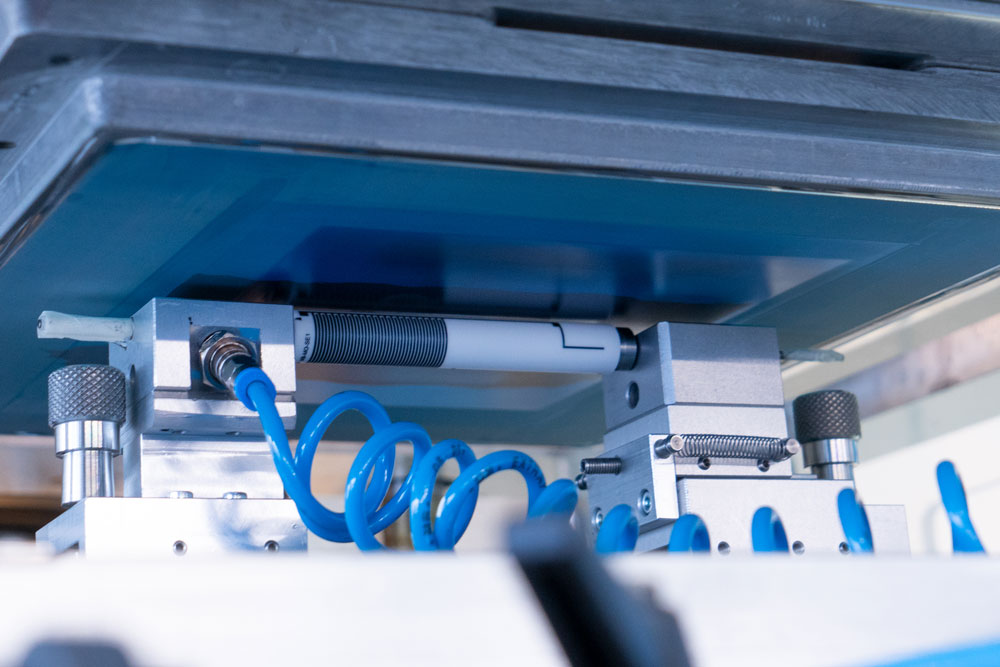

As with screen printing on planar objects, the object to be printed in tubular screen printing is positioned under a structured printing screen and the functional paste is printed onto the object by means of a squeegee through open screen meshes. This is followed by a thermal process to dry and burn in the paste. Automation of the printing process is also possible with tubular screen printing, but substrate handling is more complex.

During the printing process, a tubular object must be supported so that it can move freely along its axis and guided exactly parallel to the squeegee. The contact pressure of the squeegee causes the object to rotate under the screen so that it can be printed all around. Even the smallest position shifts of just 0.1 mm offset can impair the function of the sensitive electronic components. Positioning accuracy in the printing process is therefore particularly important. The object movement changes the release behavior of the printing screen. The functional paste must be adjusted accordingly. In addition, ceramic tubes usually have significantly larger volumes compared to the thin ceramic plates. This affects the thermal processing of the thick-film pastes. Due to the metallization coating on all sides, the conventional continuous furnace process may no longer be operational. A change to larger furnace chambers (batch furnaces) is possible but must be thermally profiled accordingly and approved for the respective thick-film pastes. This is because sintering in a batch furnace requires a significantly different temperature-time profile than the continuous furnace process.

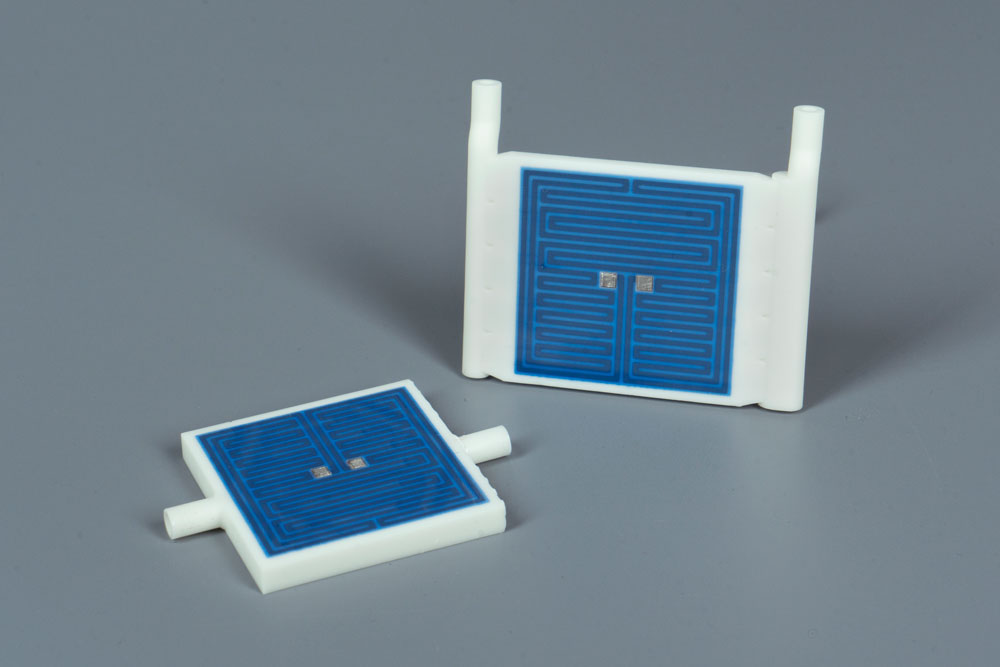

3D printing of complex geometries

In the case of particularly demanding geometric requirements, e.g. concealed channels in the ceramic, the only option is often one-off production using 3D printing. Depending on the component complexity, Fraunhofer IKTS uses different additive manufacturing technologies for this purpose. For aluminum oxide-based electronic components, vat photopolymerization (CeramVPP) has been established. In this process, a ceramic suspension produced with special binders is selectively solidified with light of a defined wavelength. This creates a ceramic 3D body layer by layer.

In this way, for example, sensor housings with complex internal stages or heating-cooling elements with integrated cooling channels can be produced. The miniaturized flow bodies produced in this way have a very large inner surface. This allows for large heating capacities to be coupled into the flowing medium from the outside or the flowing medium to be used to cool an external heat source. In particular, the cooling approach with inner channels has already been technologically demonstrated in power electronics by multilayer structures in planar form. For deviating geometries, such as tubes or complete free-form bodies, the possibility of integrating such structures has been lacking until now.

Dispense jetting – functionalization of 3D bodies

The functionalization of complex molded bodies requires suitable deposition processes. Planar or tubular outer surfaces can be coated by screen printing. Inner contours, metallization in recesses or printing over stepped sections, on the other hand, can only be realized using selective direct-writing technologies.

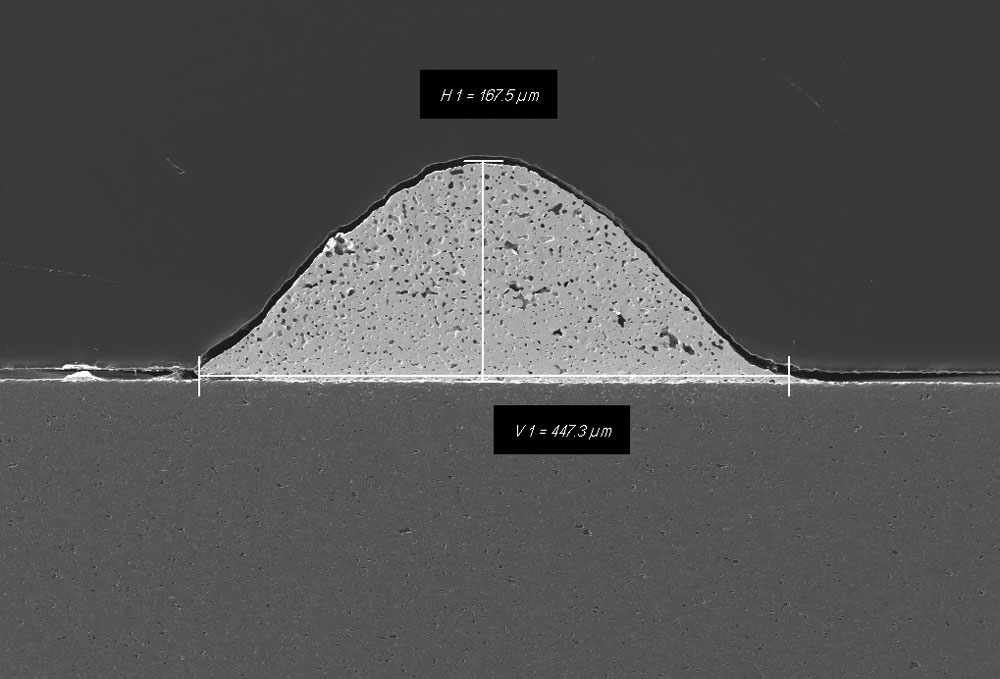

To this end, Fraunhofer IKTS is working on establishing dispense jetting of thick-film pastes. In this process, the functional pastes are applied to the substrate surface without contact by shooting them onto the surface as small drops from a nozzle. The process is similar to established aerosol printing, in which a fine particle mist is sprayed onto the surface. However, with dispense jetting, a much thicker layer can be applied and thus a greater range of functions can be achieved. In this process, too, the thick-film paste is subjected to significantly different loads than in conventional screen printing and must be adjusted accordingly.

Higher printing resolutions, new applications

Fraunhofer IKTS is currently working on optimizing the flow properties of thick-film pastes for dispense jetting, and thus achieving even further miniaturizable print resolutions on 3D bodies. Combined with the possibilities of ceramic 3D printing, this opens up completely new design options.

These new technologies make extremely high-performance and energy-efficient components producible for applications in process technology, medical devices and many other application scenarios – which can be reliably used even at high temperatures or in demanding environmental conditions. We would like to invite companies to use our technologies to improve their own products. Contact us!

More informationen

- IKTS group »Thick-Film Technology and Functional Printing«

- Development of functional pastes and inks

- Functionalization

- Industrial solution "Additive manufacturing"

- Press release "Compact ceramic thermal cyclers for accelerated Covid-19 lab testing"

- Brochure "Thick-film components for industrial applications"

- Product sheet "Integrated heater"

Stay informed: You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.