Current Research: Water treatment using autartec® systems

Autarkic, flexible, decentralized supply and storage technologies for electricity, heat, and water are gaining in importance in rural areas, where infrastructure often has to be removed as a result of demographic change. These technologies enable growth of urban areas in regions around the world with increasing populations without the need for grid expansion. They also support efforts to improve urban resilience in the face of increasingly extreme weather-related events. Under these circumstances, the autartec® alliance, an association of 11 corporations and 4 research institutions, was formed to develop advanced flexible, decentralized supply and storage technologies for modular integration into building parts, such as walls, ceilings, and staircases. The modular components can be prefabricated at low cost and are easy to use in new and existing buildings. The research findings will be demonstrated in the form of a floating house (“FreiLichtHaus”, Figure 1) that embodies the idea of self-sufficiency or autarchy. Funding of 8.2 million euros over a period of three years is being provided by the Federal Ministry of Education and Research of Germany (BMBF) to support the autartec® alliance. Fraunhofer IKTS has the task of developing and testing non-chemical and non-biological water and waste water treatment systems in line with the latest practices.

Decentralized waste water treatment systems are already the state of the art. Normally, because these systems are based on biological techniques, their performance and availability are limited. Substances such as pharmaceutical residues cannot be broken down biologically. Biological systems are also inflexible in that they cannot be switched on and off freely.

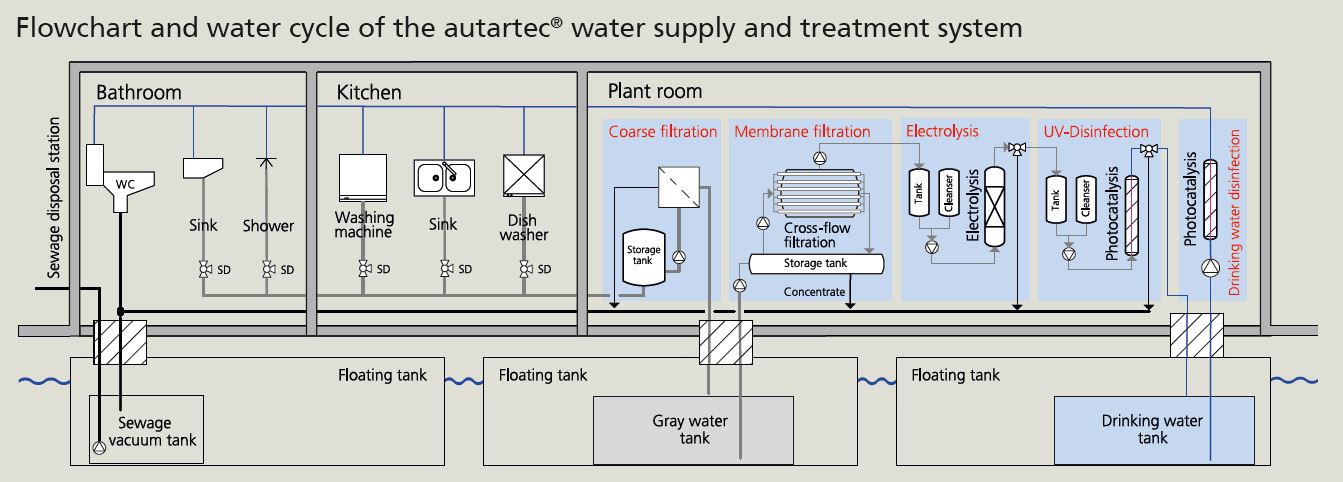

autartec® water treatment systems get around these problems by being based solely on physical and physicochemical processes, such as filtration, electrolysis, and photocatalysis. The goal of the present research was to develop reactors and process chains combining the above processes in a very confined installation space and with the highest energy efficiency possible to refine waste water up to drinking water quality. These strict purification standards can be met using functionalized high-strength ceramic materials and components, such as membrane filters and cellular monoliths. Recent results demonstrated the efficiency of these key components in waste water treatment.

The first challenge was to build test rigs for all process steps in such a way that they could be freely interconnected and operated continuously. With these test rigs, the entire process chain could be examined at pilot-plant scale. Based on compositional analysis of real domestic waste water (gray water), standardized recipes for the generation of synthetic model water fractions (e.g., shower, washing machine, and sink) were developed so that the experiments could be conducted under reproducible conditions. The results showed that particle- and bacteria-free permeates could be generated in stable operating conditions using ceramic membranes during cross-flow and gravity-flow operation. The residual organic pollutants were completely removed in an additional oxidative waste water treatment step. A specific permeate flux of up to 30 L/(m2h) was achieved during gravity-flow operation.

The results of gray water oxidation experiments demonstrated the applicability of electrochemical and photocatalytic processes for the energy-efficient breakdown of organic contaminations, especially persistent trace substances, such as pharmaceutical residues (e.g., Diclofenac). Even intermediate decomposition products generated during water treatment were mineralized completely. In parallel with the practical experiments, a conceptual design for an integrated, largely closed-loop water supply and treatment system was developed based on a detailed use and load case analysis. Because energy is limited in the autarkic floating house powered with renewable energy sources, the requirement of economical use of available energy is especially difficult to meet. The focus of subsequent development work will be on coordination of the individual components to optimize their operating behavior and cleaning performance.

Integration and demonstration of the new components in a floating, autarkic house structure are planned for 2017. This attractive and unique advertising platform will provide a springboard for future performance enhancements and acquisition of new partners for the application of advanced non-chemical and non-biological autartec® water treatment systems.