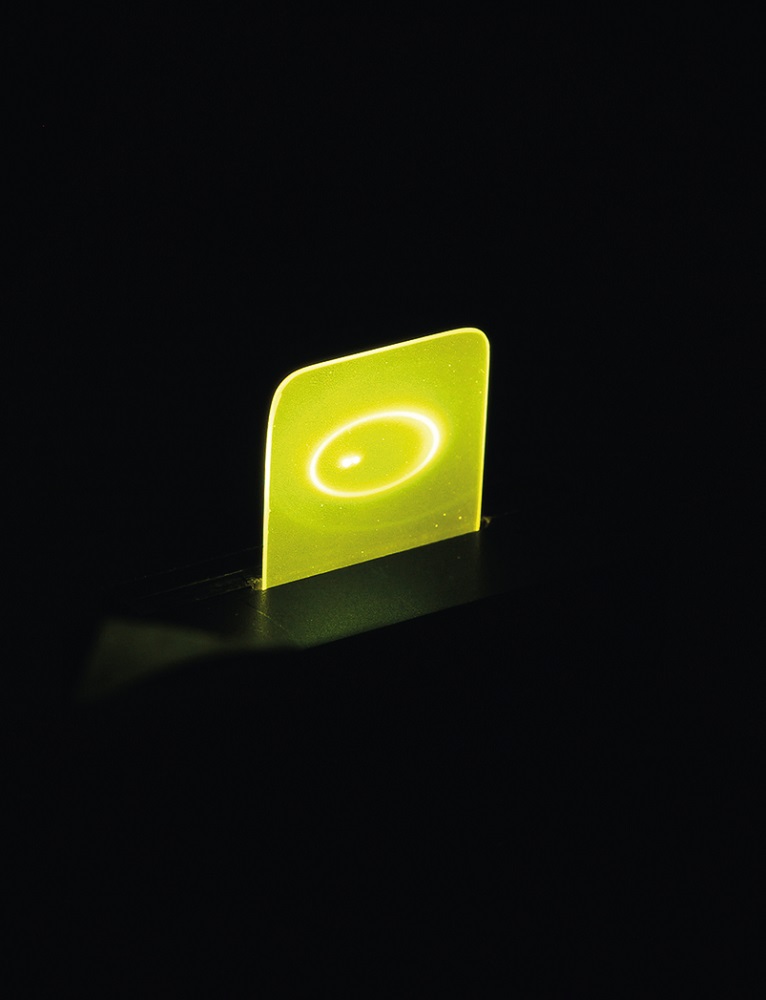

With the current surge in interest in light-converting ceramics for the high-power lighting segment, optimization and adjustment of cerium-doped Y3Al5O12 (YAG:Ce) ceramic phosphors are more important than ever. Applications in this area currently draw on both excitation possibilities for blue light of wavelength 450 nm: laser- and LED-based systems. At Fraunhofer IKTS, scale-up of the process to 4-inch ceramic phosphor wafers is being addressed in the Fraunhofer project “HeraKLED“, which stands for “Hermetically sealed luminescent ceramics for LEDs“. The aim is to enable use of ceramic light converter disks in LEDexcited packages as hermetic sealing in wafer-to-wafer technology. For scale-up, the binder-free granules that had been optimized for transparent 2-cm disks were adjusted with respect to binder content and processed in a spray drying process. Uniaxial pressing was performed alone or in combination with CIP at pressures of 100–350 MPa to generate defect-free green bodies with a diameter of 130 mm. Optimization of sintering conditions yielded crack- and nearly distortion-free disks (Figure 1).

For laser-based applications, the 4-inch YAG:Ce disks are optimized for high-power illumination in cinema and flight simulation projectors and the smaller disks for headlight systems. In order to enable new functionalities for adaptive illumination, research on the combination of laser headlights with MEMS scanning mirror technology is performed with partners.

The YAG:Ce phosphor ceramic has to be optimized for each different application in consideration of several aspects, i.e., if the excitation is performed by laser or LED, if the ceramic phosphor is in transmission or reflection geometry, if sharp image edges are required, or if the resulting white light beam should be formed and therefore the ceramic structured.

For all applications, adjustment of the scattering parameters for the intended use is crucial. At Fraunhofer IKTS, different approaches for incorporation of scattering into the ceramic are considered and compared against a transparent defect- and scattering-free YAG:Ce standard for determination of the influence of the scattering centers. Parameters, such as pore content and size, introduction of secondary phases, or dispersion of a YAG:Ce powder in a transparent ceramic matrix are investigated and compared with the aim of obtaining optimum results for various applications (see article by Ludwig and Barth).

Acknowledgments

Gabriele Eberhardt from LDT GmbH as well as Dr. Ulrich Hofmann and Dr. Thomas von Wantoch from Fraunhofer ISIT are gratefully acknowledged for their cooperation.