Test field for the development of industrial water treatment processes

Current research

No living being can exist without clean water. The sustainable purification and treatment of wastewater and its return to the natural cycle are therefore highly important. The scarcity of our most important resource, water, due to global warming is also presenting the water industry with new challenges. To ensure that water remains available at industrial sites, treating and reusing wastewater, e.g. treatment plant effluent, is therefore increasingly coming into focus. In this context, the treatment of highly saline process water and the removal of endocrine disrupting trace substances (micropollutants) and thus the fight against the spread of antibiotic resistance and fertility disorders are particularly important topics within the German industrial water management. In order to test innovative water treatment technologies and forwardlooking water utilization concepts in practice, Fraunhofer IKTS and Fraunhofer partner institutes have set up an experimental technology and innovation platform on the site of the Bitterfeld-Wolfen Joint Sewage Treatment Plant (GKW). The GKW is one of the largest and most modern wastewater treatment plants in central Germany, treating not just municipal wastewater but also the industrial wastewater from the Bitterfeld-Wolfen Chemical Park (top image).

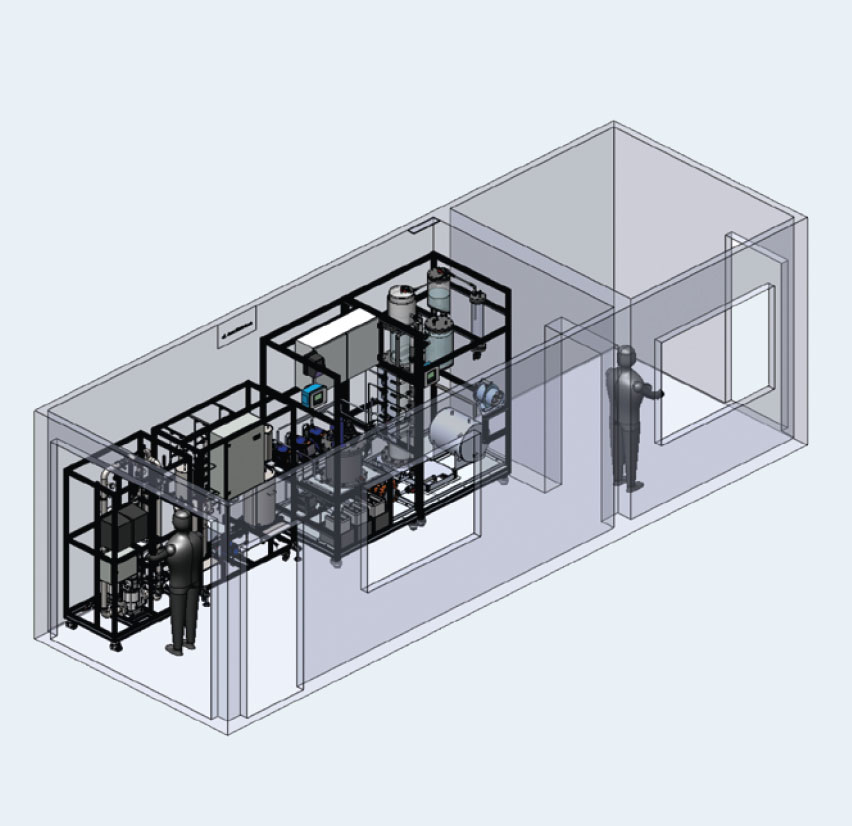

Technology platform

The platform comprises several test containers as well as test facilities in the form of interconnected modules, flexible to use, for the development, testing and transfer of new technologies. These technologies refer to water desalination and the recovery of process chemicals and raw materials, as well as water stemming from complex industrial wastewater of the Bitterfeld-Wolfen Chemical Park.

The pilot-scale test plants include filtration plants equipped with ceramic membranes, molecular and bipolar electrodialysis systems for electrochemical separation and recovery, electrolysis plants for the electrochemical total oxidation of water constituents that are particularly difficult to break down, and for sulphate separation and hydrogen generation using the RODOSAN® process. Special attention is paid to the technical replication of processes that are established on a large scale at the GKW, such as expanded granular sludge bed reactors for anaerobic wastewater treatment. This makes it possible to directly investigate the effects of new treatment concepts on the operation of the GKW and to draw important conclusions for a large-scale transfer of the technologies into practice.

With the technology platform, process optimizationsand developments can now be transferred directly, and suitable technical solutions can be offered. Transfer potential exists at the specific site of the Bitterfeld-Wolfen Chemical Park itself, in the neighboring Bayer Industrial Park, in the entire Central German Chemical Triangle and beyond.

The authors acknowledge the financial support by the German Federal Ministry of Education and Research (BMBF) in the framework of the stimulus program.

Supported by