Multifunctional test stand for the characterization of ceramic components in water treatment

Current research

The concentration of anthropogenic trace pollutants in the water cycle is constantly increasing. These substances include human and veterinary pharmaceuticals (antibiotics, hormones, contrast media), which are discharged into the wastewater system and into surface waters via hospital wastewater, private households, and industrial processes. Against this background, innovative advanced oxidation processes (AOP) are playing an increasingly important role in the treatment of water to make it a safe and pollutant-free resource.

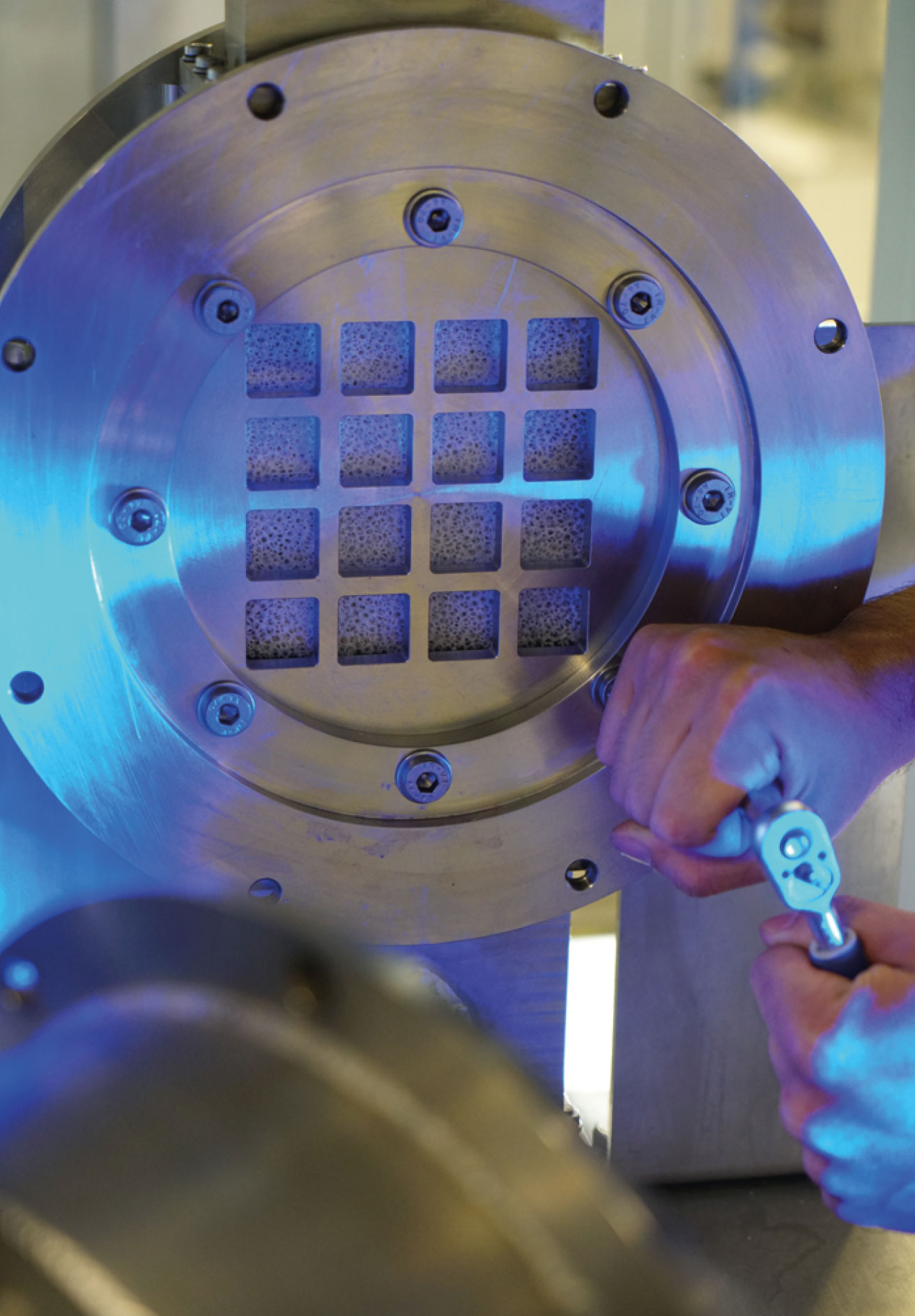

For this purpose, Fraunhofer IKTS develops complex AOP functional components based on functionalized cellular structures catalytically coated with titanium dioxide (TiO2). For the systematic further development of these multifunctional components into systems ready for practical application, a special test stand was developed, manufactured and put into operation.

Functionality

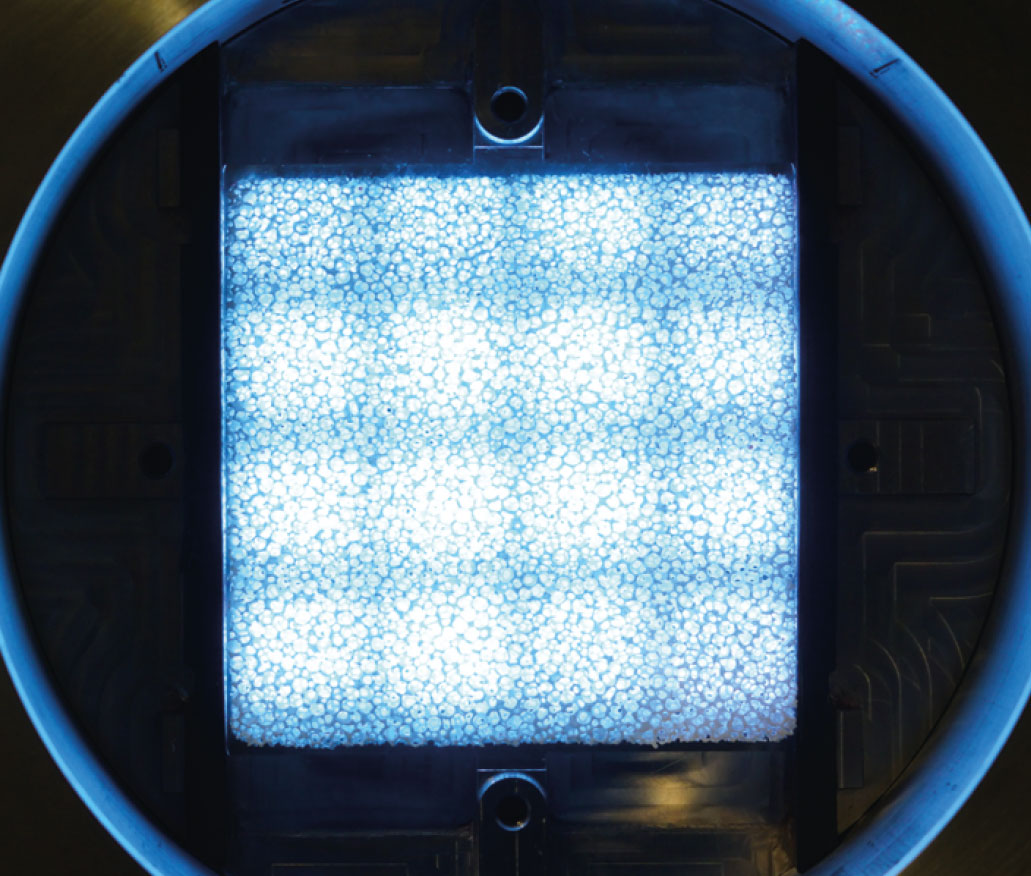

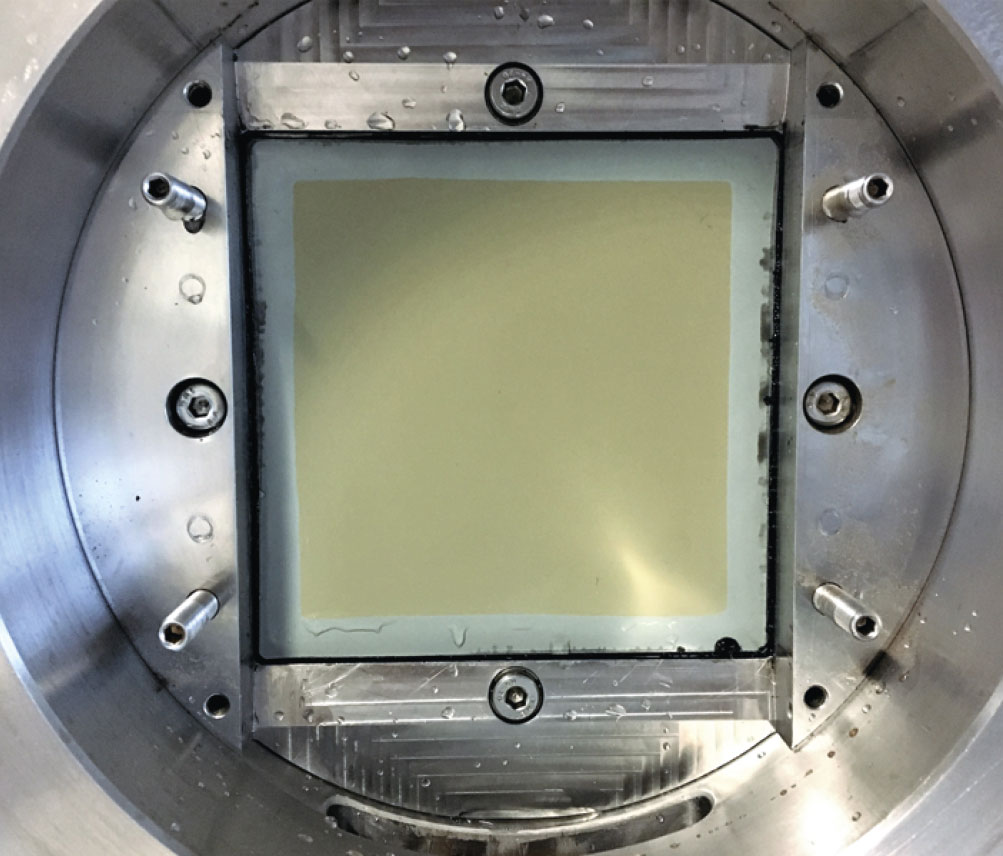

The developed multifunctional test stand combines the processes of membrane filtration and photocatalysis in a unique way. The flat ceramic membranes used are produced through the multilayer ceramic tape casting of glass-bonded silicon carbide (SiC) and subsequent co-firing. Commercial ultra-fine-grained SiC powders with narrow particle size distributions and d50 values of 3 μm and 0.7 μm are used for the membrane layers. This results in pore distributions with d50 = 1.5–2 μm and d50 = 0.25–700 μm, respectively. The membrane structure is thus in the range of microfiltration. The filtration is operated in cross-flow mode, whereby the feed side of the flat membrane is continuously overflowed in parallel. By adjusting the cross-flow velocity, it is possible to control the particle-laden top layer that forms during filtration. At the same time, the differential pressure between the feed and permeate circuits, the so-called transmembrane pressure, can also be defined. The overpressure generated on the feed side produces a largely particle-free filtrate, which is then immediately subjected to an intense photo- catalytic reaction. The catalytically generated, non-selectively reacting hydroxyl radicals are capable of achieving complete oxidation of persistent substances and converting complex water constituents into non-toxic and biologically recoverable substances. After treatment, the purified water is discharged quasi-continuously from the system via relief valves.

Outlook

In the future, the process engineering possibilities of the multifunctional test stand will be systematically expanded. In addition, the traditional low- and medium-pressure UV lamps are to be replaced by UV LEDs, which are currently under development. In the long term, this will enable a significant reduction in the energy required to reduce pollutants.

The project was funded by the European Union and the Free State of Saxony as part of the InfraPro program.

Supported by