Nutrients, such as nitrogen and phosphorus, are the keystones of high-yield agriculture. They are produced at high cost in the form of mineral fertilizers through chemical processes. At the same time, enormous quantities of nutrient-containing residues produced in animal husbandry remain unused or have to be disposed of, likewise at high cost. In terms of resource conservation and environmental protection, recycling and utilizing valuable nutrients from such residues represents a cost-effective and sustainable alternative to mineral fertilizers. Thanks to the development and combination of key technologies for nutrient recycling, nutrient cycles can be closed efficiently.

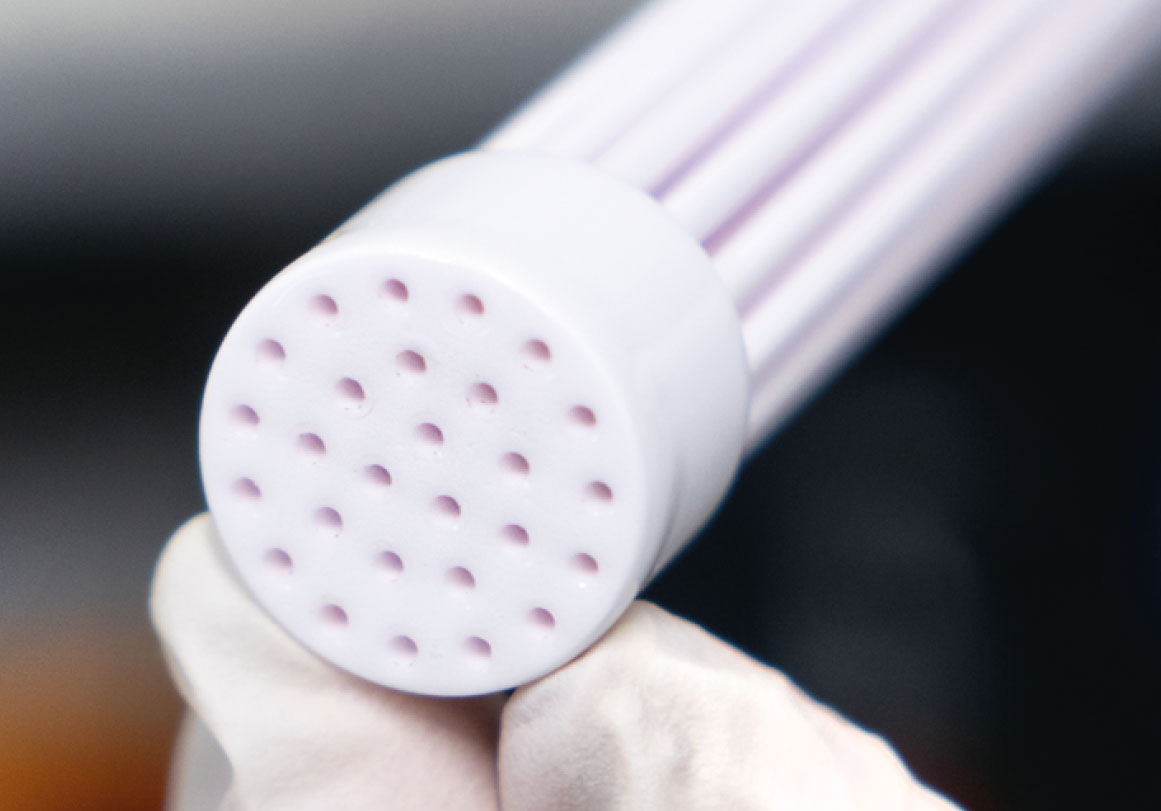

Membrane extraction is a promising technology for the recovery of ammoniacal nitrogen from aqueous agricultural residue streams. Temperature-stable, chemically resistant and abrasion-resistant materials are required for the process. For this application, Fraunhofer IKTS is developing and investigating robust ceramic membrane contactors based on single-channel tubes made of aluminum oxide which can meet the high requirements. A durable water-repellent (hydrophobic) membrane surface is one essential property required for the process. Such hydrophobic surface coating based on silanes has been successfully developed at IKTS. The coating prevents wetting of the ceramic membranes with the aqueous media and ensures a stable, gaseous phase boundary in the membrane pores.

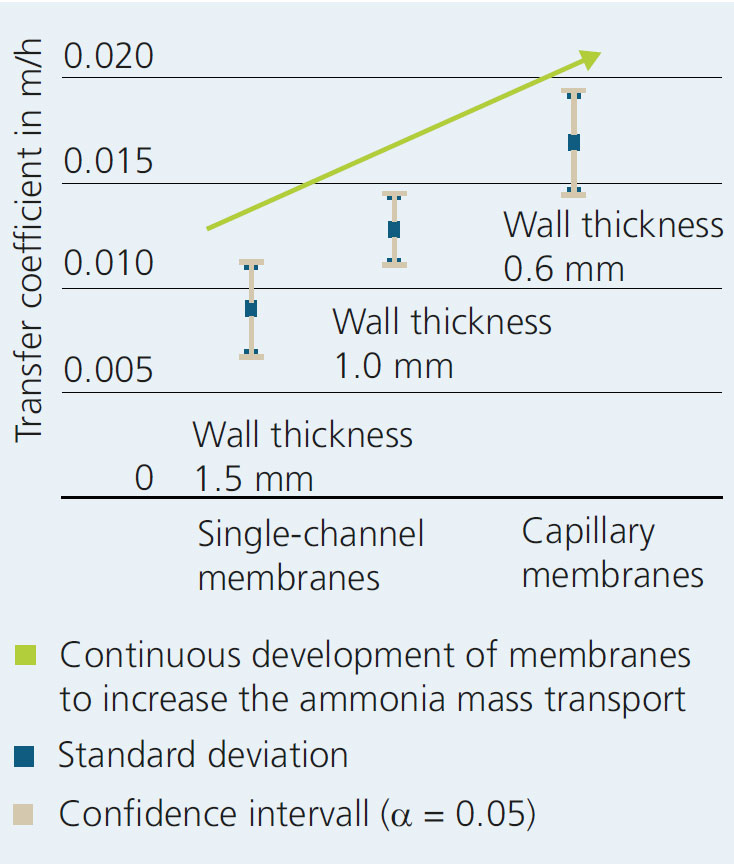

By setting a partial pressure gradient, the gaseous ammonia present in the residual stream passes through the membrane pores and can be extracted from the stream. The key process parameters have already been extensively evaluated on a technical scale. The diffusion path through the membrane layers is a limiting factor in extraction. With ceramic capillary membranes, manufactured at IKTS (top picture), with reduced wall thicknesses (600 μm) compared to conventional, ceramic single-channel tubes (1.5 mm), the ammonia transfer could be increased by almost 90 % (bottom figure). Ammonia can be redissolved in a sulfuric acid solution after passing through the membrane, producing ammonium sulfate solution – a valuable approved fertilizer in liquid form.

One advantage of the process is that ammoniacal nitrogen can be selectively recovered and impurities as well as pollutants are retained by the membrane.

Other applications can also be realized with ceramic membrane contactors, such as the recovery of ammonium in industrial processes for the subsequent decentralized production of hydrogen.

The scientific work is supported within the growth core abonocare® by the funding program “Innovative Regional Growth Cores” (German: Innovative regionale Wachstums-kerne) of the German Federal Ministry of Education and Research (BMBF).